Ultimate Guide_Polish Polycarbonate You Need To Know

Discover the art of polishing polycarbonate with our expert guide. Learn proven methods and easy steps to achieve a clear, radiant shine.

Polishing and cleaning polycarbonate materials is a professional gig. Because with a simple mistake, the whole process can end in vain. On the other hand, a simple unconsciousness can damage the surface even badly. So, it is important to know how to polish polycarbonate like a pro or hire professionals.

In this article, we will discuss the way of polishing polycarbonate like a pro.

Polycarbonate Polishing Guide

Here is the guide to polishing a polycarbonate plastic like a pro.

Necessary Supplies

Before starting the polishing method we need to prepare the polycarbonate. To do so, we have to gather some necessary supplies that will be needed during the process. However, there are lots of polishing methods available in the market.

Which one of them will cover your needs depends on how much polishing your workpiece needs. Therefore you have to gather microfiber cloths, water, mild soap or dish detergent, non-abrasive components, and water-based wax or polish.

Remove Dirt

After gathering the necessary supplies, we have to clean the surface of the polycarbonate. Most of the time the surface of the plastic might hold mud, debris, offshoots, or other dirt. Washing them with clothes will create extra scratches on the surface.

So, you have to apply some dirt-removing tactics. However, you can easily remove the dirt from the surface by using mild soap or dish detergent and clean water. The soap will soften the grip of the dirt and the clean water will wash all of them out.

Apply Cleaning

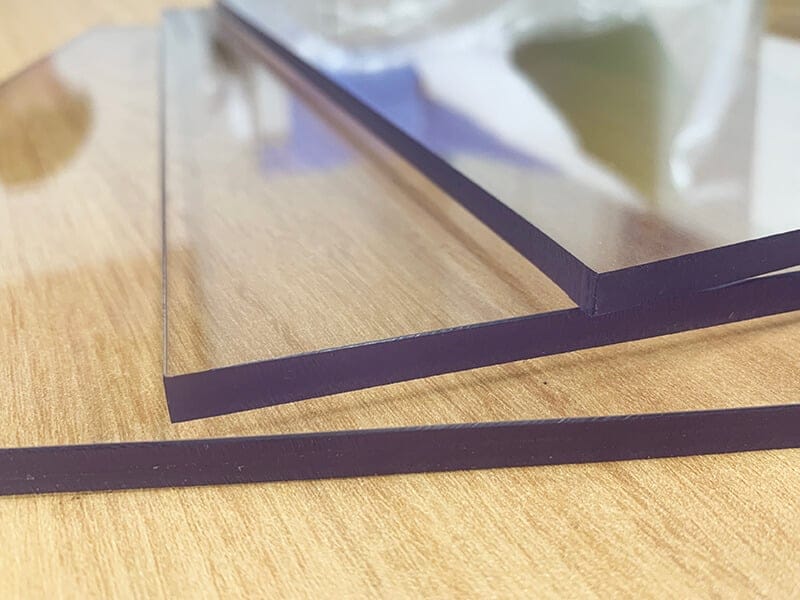

Cleaning is also the same as dirt removal, but it mentioned the deep cleaning of the surface and edge. Most polycarbonate plastics have smooth and transparent surfaces, which is why they need more care than other materials.

After removing the dirt from the surface the polycarbonate will be exposed to the scratch and other damages. Some of them will disappear with proper deep cleaning. So, before applying final polishing, we have to use deep cleaning.

Use Microfiber Cloth

When the surface and edge are cleaned properly, we have to apply microfiber cloths to dry the entire polycarbonate. Microfiber cloths are better than any other clean cloths. They soak up water drops and other cleaning materials from the surface.

While washing the polycarbonate we must maintain medium washing pressure. Otherwise, it will deepen the damage instead of softening it.

Use Any Suitable Polishing Method

It is necessary to fully clean the surface and edge before applying polishing the polycarbonate. However, the polycarbonate and other plastic and glass materials need deep cleaning before polishing.

Therefore, polycarbonate supports plenty of suitable polishing methods including wet sanding, vapor, sanding, and chemical polishing. Different types of damage and scratches are needed for different types of polishing.

Before jumping to any conclusion, you must have proper knowledge and experience about those methods. On the other hand, you could hire professionals to do the job.

Repeat Cleaning with water

When the cleaning and polishing finally get done, then you have to apply washing the polycarbonate with previous cleaning materials. Then carefully remove the water and wet waste that is produced by the polishing method. It will soften the surface and become more shiny and transparent.

Ultimate Polycarbonate Polishing Methods

Polycarbonate polishing is a versatile process. You can either apply one method or experiment with them to find out which one works best. Here are the most used polishing methods that are suitable for polycarbonate materials.

Vapor Polishing

It is a most advanced method of polishing that is also known as solvent polishing. This method usually uses the chemical vapor technique. Initially, it heated the rough area to an optimum temperature and then the material rebuilt the atomic structure to its previous state with Weld-ON 4 solvent.

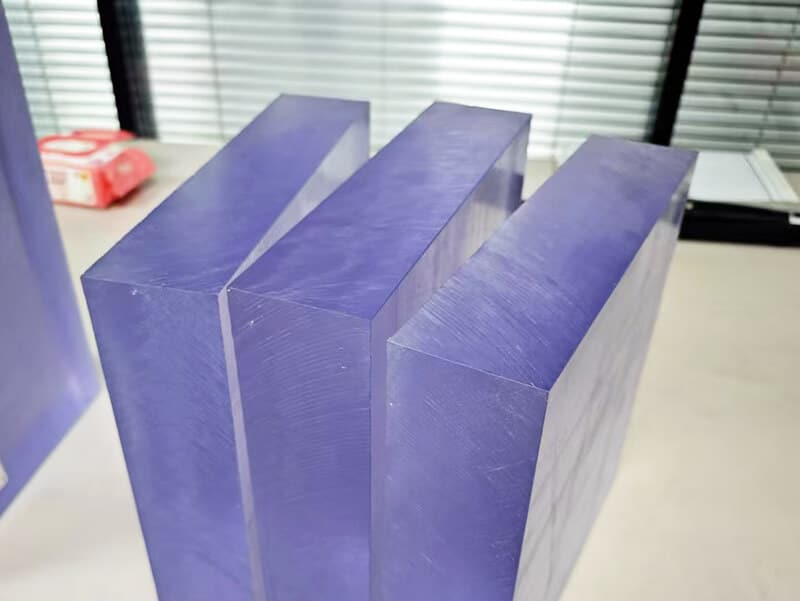

So, the roughness of the polycarbonate reduces itself and makes the surface softer than before. This process is efficient for highly transparent polycarbonate applications like windscreens, laboratory equipment, and optical lenses.

Sandy Polishing

Sandy polishing is performed by either wet or dry methods. This process is mostly used for polishing deep scratches or damages. This polycarbonate polishing method is performed with different grit-counted sandpapers. Sandpaper polishing is widely common for hard finishing in wooden materials.

But with the proper grit count between 80, 200, 400, 600, 800, and 1000, you can remove the polycarbonate materials. Generally, it is a cheaper method for polishing but provides better results for deep damages like cuts and rough scratches. You can apply this method with water or without water. The result will vary with those different processes.

Chemical/Optical Mechanical Polishing

This polycarbonate polishing covers mechanical, chemical, and ultrasonic polishing at the same time. This method also works like vapor polishing but in different ways. However, chemical polishing introduces the methylene chloride solvent to refurbish or restock the parallel dissolution of the upper layer. Then the solvent changes the formation and clears the scratch or rough surface of the polycarbonate.

Flame Polishing

This method is also described as the thermal treatment. It uses a special kind of torch flame to provide controlled flame. Though flame polishing is mostly used to soften the edge of a plastic sheet, it also works better in polycarbonate surface polishing.

Usually, the thermal treatment uses a controlled oxidizing flame to melt the material. Then it loses the heat, returns to its natural state and becomes more glossy.

Buffing Polishing

Buffing the material surface is quite popular for metal and plastic materials. For instance, the polycarbonate sheets also get better polishing treatment with this method. Initially it uses a spinning cloth wheel called buffing-disk.

While polishing the polycarbonate, don’t press the product hard against the spinning mop with contentious pressure. Rather use the workpiece agents the spinning wheel press-lose, press-lose method. So, the polishing will be even and shiny.

Pro Tips

Here is some user advice you have to remember.

Final Words

Proper polishing is a great way of achieving super transparent and shiny surface output. This article covers all the essential details about how to polish and clean rough polycarbonate surfaces and edges. Sometimes, two or three polishing methods are needed for a perfect result.

If you are looking for a trustworthy supplier of polycarbonate components with polished surfaces and edges, contact UVTECO now!

Related Blogs

Looking for a trustworthy Supplier

Need a Trustworthy Supplier of Plastic, Foam, Sponge, Rubber, Metal, and Machining Solution. Click the Button, We Will Be In Touch With You As Quickly As Possible.