About infrared transmitting polycarbonate

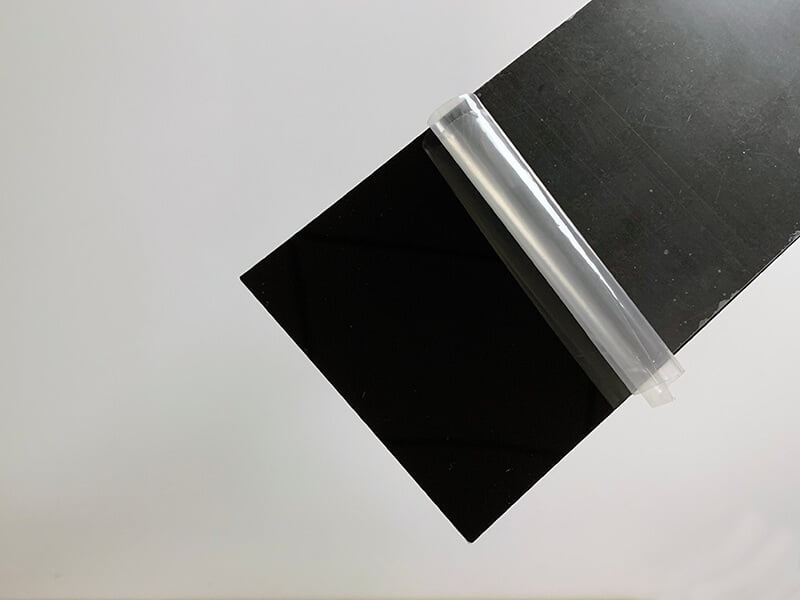

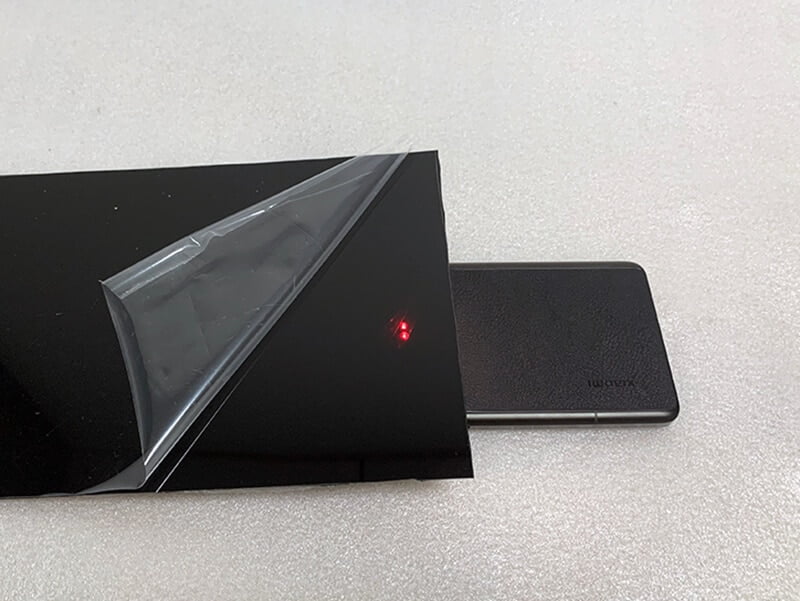

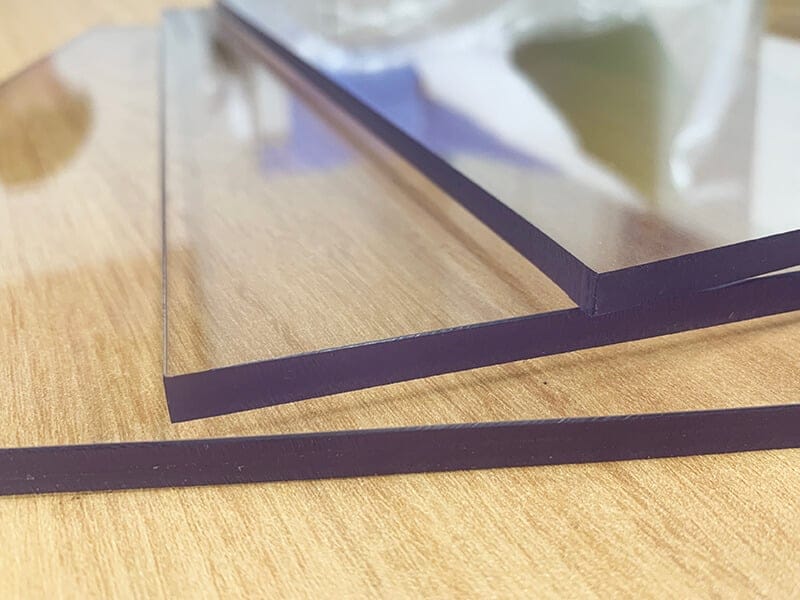

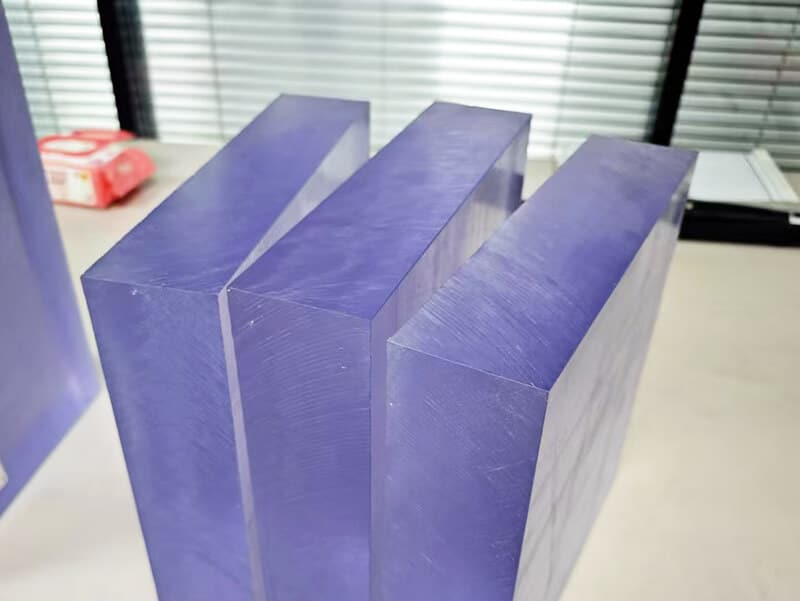

Infrared-transmitting polycarbonate can transmit infrared rays and block ultraviolet (UV) and visible light. Some people call it “IRT polycarbonate” or “IR polycarbonate”. It is recommended to be used for the transmitters and receivers of infrared rays, for example, Cameras, Rifle Optics, Sighting Devices, Unmanned Aerial Vehicles, Automatic Drive, Home Automation, etc.

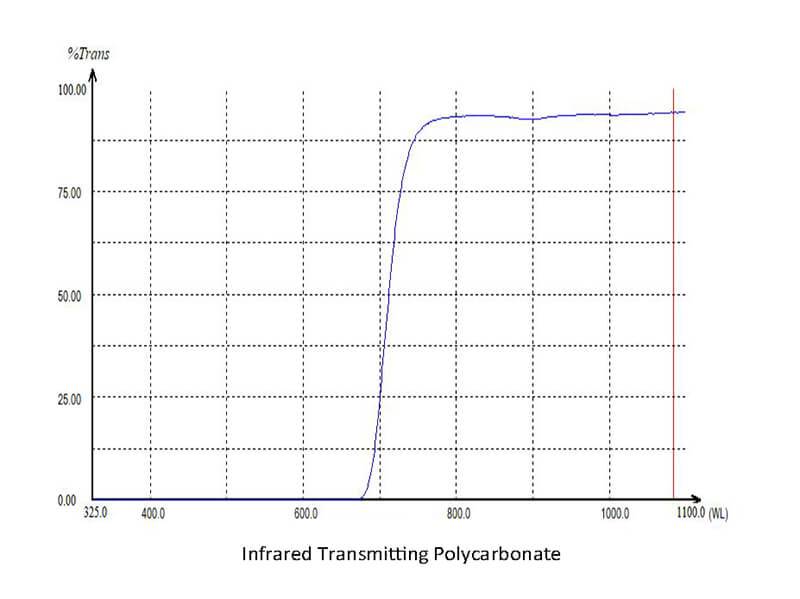

UVTECO Infrared Transmitting Polycarbonate is made from specifically formulated polycarbonate plastic. It offers a standard threshold value of 700 Nanometers and custom threshold values from 570 to 800 nanometers.

As a leading supplier of IRT polycarbonate sheets in China, UVTECO offers different thicknesses from 0.8mm to 3mm. We also offer machining services, such as cutting to size, die-cutting, CNC routing, thermal forming, silk-screen printing, and injection molding.

Specification of infrared-transmitting polycarbonate

Infrared-transmitting Polycarbonate Sheet

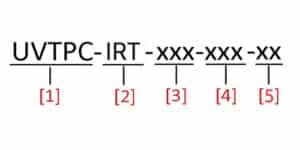

| No. | Code Name | Description |

|---|---|---|

| 1 | UVTPC | UVTECO Polycarbonate |

| 2 | IRT | Infrared-transmitting |

| 3 | xxx | Threshold Value |

| 4 | xxx | Thickness |

| 5 | xx | Ending Code |

| No. | Item | Description |

|---|---|---|

| 1 | Product Name | Infrared Transmitting Polycarbonate Sheet |

| 2 | Color | Black |

| 3 | Threshold Value | 570, 650, 700, 780, 800 Nanometer or Custom |

| 4 | Infrared Transmittance | >88% |

| 5 | Main Material | Polycarbonate plastic |

| 6 | Thickness | 0.8mm, 1mm, 1.2mm, 1.5mm, 2mm, 3mm |

| 7 | Thickness Tolerance | <3% |

| 8 | Transmission of Visible Light | <3% |

| 9 | Transmission of UV Light | <3% |

| 10 | Machining Service | YES |

| 11 | Custom Service | YES |

Grade of UVTECO infrared-transmitting polycarbonate

UVTECO provides high-quality infrared-transmitting polycarbonate in different grades for different applications. In the meantime, we also provide custom parts through the injection molding process.

The standard Threshold Value is 700 Nanometers, but we provide custom Threshold Values for different applications.

| Item | Model | Grade | Infrared Ray Transmittance (%) |

|---|---|---|---|

| IRT Polycarbonate Sheet | UVTPC-TRT-700-N | Normal | >88% (850~1100nm) |

| IRT Polycarbonate Sheet | UVTPC-TRT-700-SR | Scratch Resistant | >88% (850~1100nm) |

Properties of infrared-transmitting polycarbonate

| Properties | Unit | Value | Testing Method |

|---|---|---|---|

| Thickness | mm | 0.8mm, 1mm, 1.2mm 1.5mm, 2mm, 3mm | |

| Standard Threshold Value | Nanometer | 700 | |

| Available Threshold Value | Nanometer | 570, 650, 700, 780, 800 | |

| Infrared Transmission | % | >88 | 2mm thickness; 850 to 1100 nm; |

| Visible Light Transmission | % | <1 | 2mm thickness; 400 to 700 nm; |

| Density | g/cm^3 | 1.2 | ASTM D792 |

| Water absorption, 24H | % | From 0.5 to 0.7 | ASTM D570 |

| Refractive Index | 1.59 | ASTM D542 | |

| Melt Index | g/10 min | 10 (300°C/5.0KG) | ASTM D1238 |

| Notch impact Strength | J/M | 80 | ASTM D256 |

| Tensile Strength at Break | MPa or N/mm² | >630 | ASTM D638 |

| Elongation at Break | % | 100 | ASTM D638 |

| HDT, 1.82MPa, 6.4mm | °C | 125 | ASTM D648 |

| Hot deformation temperature 1.80 MPa annealing | °C | 132 | ISO 75-2/A |

| Flammability | / | V-2 | UL94 |

| Surface hardness (Mormal grade) | / | 2B or HB | 750g |

Main Usage of IRT Polycarbonate

Anthropomorphic Robot

Pilotless Automobile

Robot Vacuum Cleaner

Camera of Robot

Unmanned Aerial Vehicle

Traffic Camera

Handheld Scanner

Smart faucet

Smart toilet

VR Glasses

Contact UVTECO for machining Polycarbonate service

Related Products of Infrared-transmitting polycarbonate

Related Blogs about Infrared-transmitting polycarbonate

FAQ about IR transmitting Polycarbonate

Looking for a trustworthy Supplier

Need a Trustworthy Supplier of Plastic, Foam, Sponge, Rubber, Metal, and Machining Solution. Click the Button, We Will Be In Touch With You As Quickly As Possible.