PEEK plastic in all forms

PEEK Sheet, PEEK Film, PEEK Rod, PEEK Tube, Injection Molding Parts, Machining Service…About PEEK plastic

PEEK Plastic (polyetheretherketone) belongs to the polyaryletherketone (PAEK) family and is a semicrystalline thermoplastic. It is an almost perfect plastic for parts and components used in environments with high temperatures and high corrosion.

PEEK Plastic’s unique chemical structure makes it incredibly strong and dimensionally stable under load and in the harshest environments. The operating temperature is up to 260°C (480°F), and the melting point is around 341°C (646°F). Therefore, PEEK Plastic is often used in hot water or steam environments.

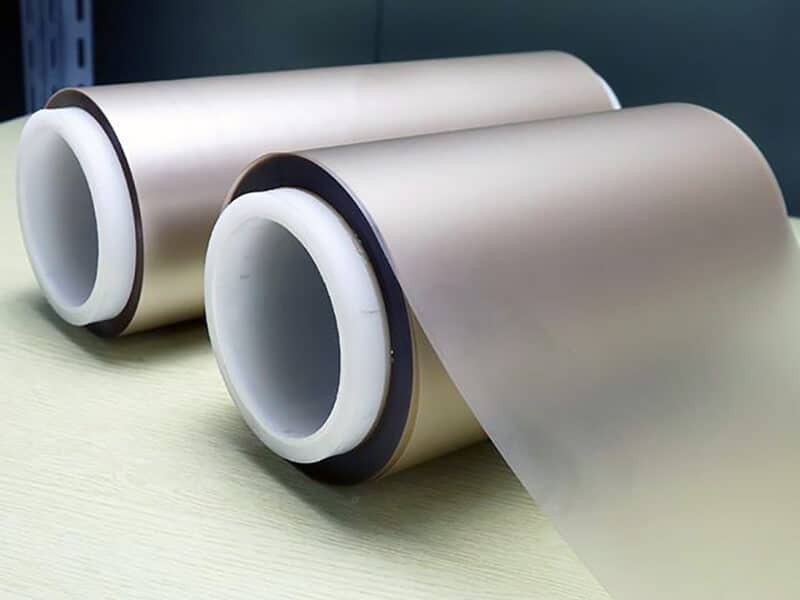

PEEK plastic is naturally light brown or tan and available in black. It is usually extruded into sheets, films, rods, tubes, and complicated parts by injection molding. Unlike other polymers, PEEK plastic offers machinability similar to that of metal. PEEK Plastic is also available in different grades, such as Unfilled Grade, Glass-Filled, Carbon-Filled, Antistatic PEEK, Etc.

As a popular material, PEEK plastic is used for Semiconductor components, automotive washers/bearings, aerospace parts, oil and gas components, medical devices and implants, and pump/valve components, among other uses.

Specification about PEEK plastic

Profile/Shape

Grade

Color

Production process

PEEK sheet

PEEK Film

PEEK Rod

PEEK Tube

Remark

Properties of PEEK Plastic

Main Feature of PEEK Plastic

Main Usage of PEEK Plastic

Main Industry

Can’t find what you need? Or have a technical question?

Leading Supplier of PEEK Plastic in China

UVTECO is a leading supplier of PEEK Plastic products, including sheets, films, Rods, and tubes. You can choose the custom PEEK materials in different grades from UVTECO, such as glass-filled, carbon-filled, PTEF-filled, and conductive grades.

UVTECO usually stocks high-quality PEEK sheets, films, rods, and tubes in standard sizes for fast delivery to global clients. We also provide machining services, including CNC Machining (three-axis and five-axis), Die-cutting, turning, injection molding, engraving, etc.

Today, UVTECO, an ISO-certified company, provides high-quality PEEK-base products/parts/components for over 2,500 clients in more than 45 countries.

Contact UVTECO for machining PEEK service

Related Blogs about PEEK Plastic

Frequently Asked Questions about PEEK Plastic

Looking for a trustworthy Supplier

Need a Trustworthy Supplier of Plastic, Foam, Sponge, Rubber, Metal, and Machining Solution. Click the Button, We Will Be In Touch With You As Quickly As Possible.