Delrin vs. UHMW: Exploring the Battle of Engineering Plastics

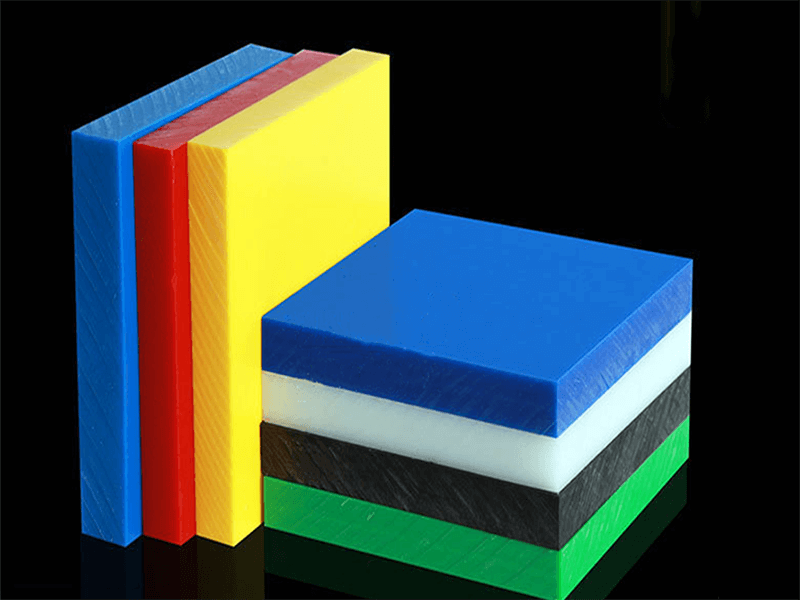

UHMW and Delrin are synthetic solid materials that do not stick together much. UHMW is known for being strong and not reacting with chemicals, while Delrin is known for being stiff and not changing shape.

UHMW is immune to most chemicals, bacteria, and UV light, but it does not have the same resistance to creep as Delrin. Both materials are often used in manufacturing gears, bearings, and wear strips, among other things.

Delrin: Everything you need to know

Polyoxymethylene (POM), also known as acetal and by the brand name Delrin, is a material for injection molding and machining. It is an engineering-grade thermoplastic with a semi-crystalline structure, excellent physical stability, high strength, a wide temperature range, and low friction. Delrin has many great qualities that make it ideal for making precise and long-lasting parts.

Common characteristics of Delrin

Delrin plastics have many qualities that make them useful for many uses. This plastic is strong and stays in its original shape to be used for a long time. Here are some common characteristics of Delrin plastics:

Common Applications of Delrin

Delrin is an industrial thermoplastic that can be used for many different things. So, it is often used in parts that need to be precise and have low surface friction, stiffness, and good physical stability. Delrin can also keep its shape and size even if it is subject to changes in humidity and temperature. Delrin can be used for many different things, including:

Advantages of Delrin

Disadvantages of Delrin

UHMW: Everything you need to know

UHMW is a semi-crystalline thermoplastic made of long chains. It is a very thick form of polyethylene. UHMW is made when molecules of ethylene stick together. The molecules that make up UHMW are much longer than those that make up other types of polyethylene. These molecules can act as catalysts and usually have positively charged metal ions between negatively charged cyclopentadienyl anions.

UHMW can be made into a sheet, stick, strip, or tube by pressing, sintering, ram extruding, or gel spinning. It was quickly seen as a flexible material that could be used in many ways.

Common Characteristics of UHMW

Common Applications of UHMW

UHMW is used in a lot of different ways, from industry to medicine to wire and cable:

Advantages of UHMW

Some of the advantages of UHMW are:

Disadvantages of UHMW

UHMW may become brittle at low temperatures, and at high temperatures, it may lose some of its strength to impact. This makes it not a good choice for places with very high temperatures.

Comparison Between Delrin Vs. UHMW

| Material | Delrin | UHMW |

|---|---|---|

| Short description | Delrin is a very flexible engineering polymer that was the first acetal resin in the world. | Ultra High, Molecular Weight Polyethylene, is what UHMW stands for in short. It is sometimes called UHMW-PE as well. |

| What ingredients are used to make this | Delrin, also known as POM-H (homopolymer acetal), is a type of POM material. The other kind of POM material is POM-C (copolymer acetal). | Thermoplastic polyethylene includes ultra-high-molecular-weight polyethylene (UHMWPE or UHMW). UHMWPE does not smell, taste, or harm you in any way. |

| Applications | Gears, bearings, bushings, wheels, fittings, and parts that keep electricity from moving through them are all common applications of Darlin. | UHMW is often used in belt scrapers, chain guides, idler rollers, sprockets, packing machinery parts, and gears because it is solid and durable. |

| Characteristics | Delrin plastic is strong, stiff, and immune to impact, creep, abrasion, friction, and wear and tear. | UHMW is rugged, smooth, and long-lasting, and it has a high tensile strength. |

| Pros | Due to its improved mechanical strength, Delrin is very resistant to wear and tear. | Some of the best things about UHMW are that it is strong, lasts long, and can take a lot of punishment. |

| Cons | Not a good choice for storing food because acidic foods can easily break it down. | There might be better material for parts that need to be very precise. |

Final words

Delrin and UHMW Plastic are both popular engineering plastics for industrial parts with different physical properties. Delrin, also known as acetal, offers superior stiffness and dimensional stability, making it the preferred material for precision mechanical parts like gears and bearings. Its mechanical properties and machinability make it a popular choice in industries such as manufacturing and aerospace.

UHMW and Delrin are both highly regarded engineering plastics with unique strengths. Delrin, also known as acetal, offers superior stiffness and dimensional stability, making it the preferred material for precision mechanical parts like gears and bearings. Its mechanical properties and machinability make it a popular choice in industries such as manufacturing and aerospace. UHMW is an excellent choice for applications that require exceptional wear resistance, impact strength, and low friction. Its properties make it ideal for various industries such as automotive, construction, and medical.

If you don’t know how to choose, contact UVTECO for help. UVTECO is a leading supplier of Acetal plastic, UHMW Plastic, and machining services in China.

Related Blogs

Looking for a trustworthy Supplier

Need a Trustworthy Supplier of Plastic, Foam, Sponge, Rubber, Metal, and Machining Solution. Click the Button, We Will Be In Touch With You As Quickly As Possible.