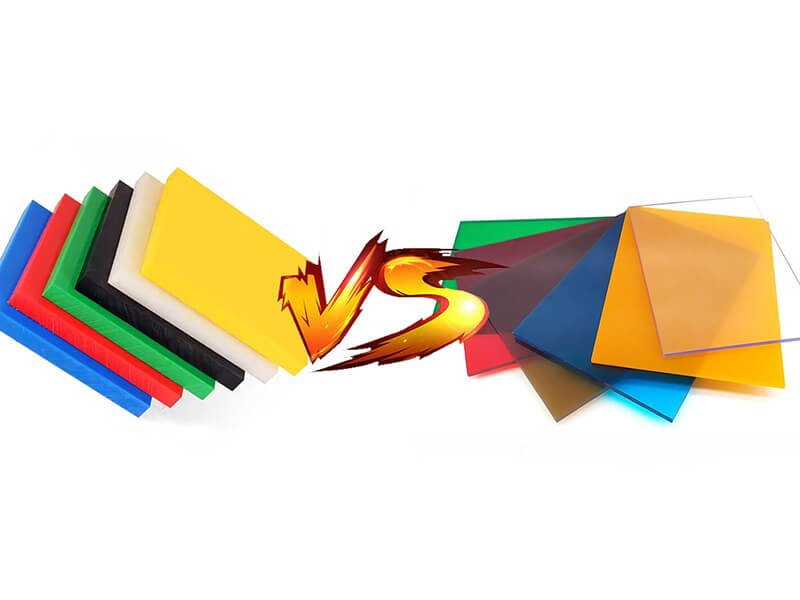

HDPE Vs. Acrylic Plastic: Breaking Down the Pros and Cons

HDPE Plastic, also known as high-density Polyethylene, triggers a higher level of durability and strength in the final production. HDPE is popular among plastic-item manufacturers. Acrylic, also known as Polymethyl methacrylate, has a short form: PMMA. This transparent thermoplastic material is considered versatile and used in various industries, such as glass manufacturing and paint production.

Understanding the context of HDPE Vs. Acrylic is crucial for product design, determining the production cost of associated final products, projecting requirements against potential outputs, and more. This article informs the pros and cons of each material to assist engineers, designers, and manufacturers in the suitable material selection process.

HDPE Plastic: Everything you need to know

The invention of HDPE includes two stages. First, in 1951, Paul Hogan and Robert Banks discovered the polymerization process of producing polypropylene. Second, in 1953, Nobel Prize winner Karl Ziegler used their concept and foundational research to produce HDPE.

At present, slurry polymerization is used to produce HDPE. In this case, intense heat is applied to petroleum, forming ethylene. Then, the slurry is made by mixing a catalyst and a small amount of liquid ethylene in a reactor. Finally, earlier produced ethylene gas is inserted into the reactor to polymerize the monomers. And the HDPE particles are formed.

Common Characteristics of HDPE Plastic

High-density polyethylene showcases various base characteristics you must know to understand this material better.

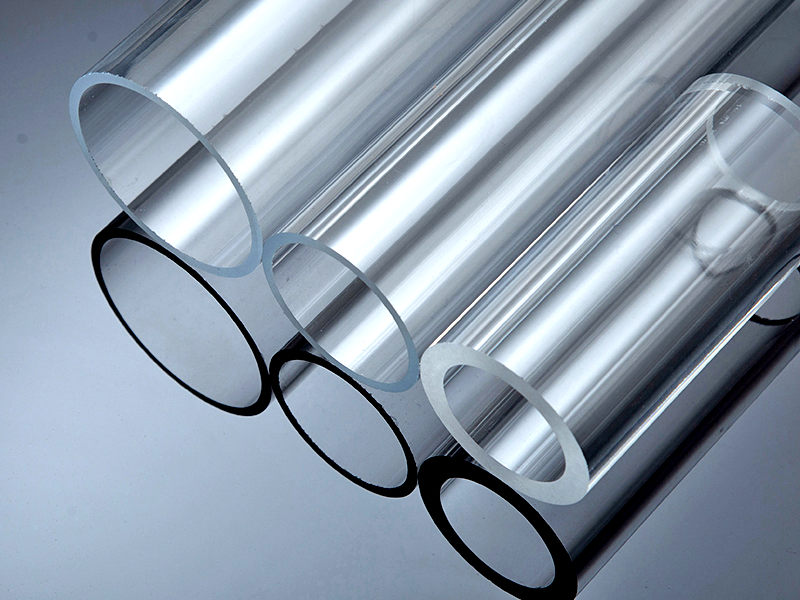

Common Applications of HDPE Plastic

Below are the most common applications of HDPE Plastic in various industries.

Advantages of HDPE Plastic

Below are the advantages of using HDPE to manufacture the respective products.

Disadvantages of HDPE Plastic

Below is a list of disadvantages associated with HDPE.

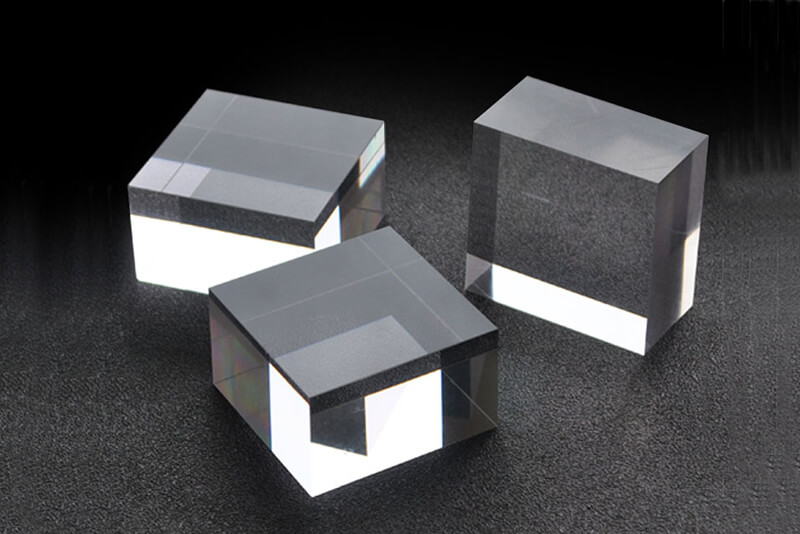

Acrylic Plastic: Everything You Need to Know

In 1928, German chemist and engineer Otto Haas and his team created the first clear and solid form of Acrylic by polymerizing methyl methacrylate. In 1933, they commercially marketed this material under the trademark “PLEXIGLAS.”

Typically, two procedures are applied to produce Acrylic: bulk and suppression polymerization. However, bulk polymerization is commonly used. In this process, the polymerization of monomer methyl methacrylate (MMA) and a catalyst like organic peroxide occurs. Second, this mixture is carefully mixed, poured, and sealed into a mold to apply controlled heating.

Common Characteristics of Acrylic Plastic

Below are the must-know characteristics of Acrylic Plastic.

Common Applications of Acrylic Plastic

Here, we list the typical applications of Acrylic.

Advantages of Acrylic Plastic

The following are the advantages of using Acrylic in various product productions.

Disadvantages of Acrylic Plastic

Here are some cons of Acrylic plastic:

Comparison Between HDPE Vs. acrylic Plastic

| Type | HDPE | Acrylic |

|---|---|---|

| Short description | HDPE is high-density Polyethylene | Acrylic is a transparent thermoplastic material |

| What ingredients used to make this | Liquid and gas ethylene from petroleum, catalysts | Monomer methyl methacrylate (MMA) and a catalyst like organic peroxide |

| Applications | HDPE is used to manufacture pipes, bottles, lids, auto parts, trash bins, etc. | Acrylic is used to produce vehicle’s lights, skylights, windows, etc. |

| Characteristics | It provides a higher degree of strength, stiffness, and durability. It has a low moisture absorption rate. And recyclable. | Transparent, strong, and stiff. It is also resistant to various chemicals. |

| Trade Name | HiTec, Playboard, King Colorboard, Paxon, etc. | Crylux, Hesalite, Plexiglas, Acrylite, etc. |

| Price | Per Ton price is $1,143 to $1,250 | Per Ton price is $2,350 to $2,550 |

Final Words

HDPE plastic differs from acrylic plastic, but some plastic parts/components can be made from either. Acrylic plastic will be the correct material if you need transparent plastic parts, but HDPE will be the suitable material if you need abrasion-resistant components.

If you don’t know which to choose for your project, please get in touch with UVTECO. As an expert in material and machining solutions, UVTECO is a trustworthy supplier of HDPE and acrylic plastic from China, and we will help you to choose the right material for your projects.

Related Blogs

Looking for a trustworthy Supplier

Need a Trustworthy Supplier of Plastic, Foam, Sponge, Rubber, Metal, and Machining Solution. Click the Button, We Will Be In Touch With You As Quickly As Possible.