Nylon 101: Quick Insights on Properties, Types & Applications

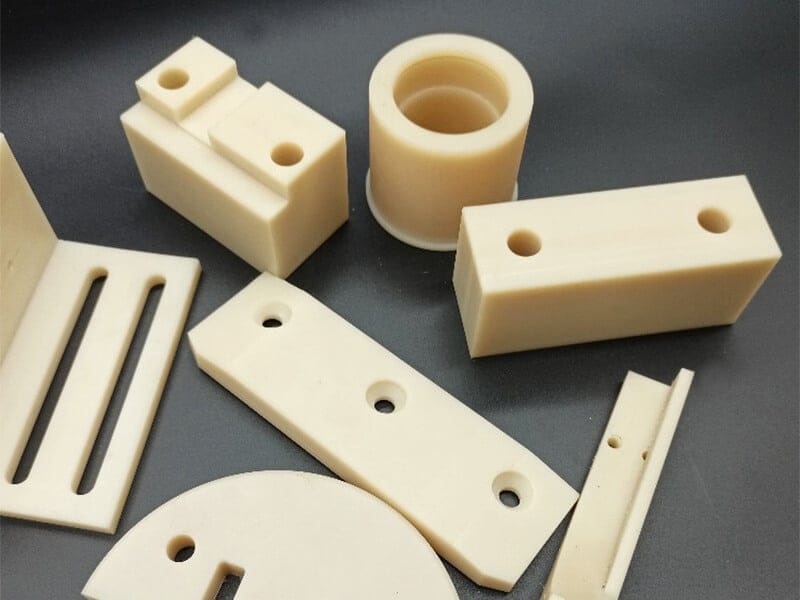

Explore the versatility of Nylon with our quick guide, covering essential properties, types, pros, cons, and practical applications.

Exploring Nylon 101: Discussion on This Versatile Plastic

Nylon 101 is one of the best construction materials. This polyamide form of plastic incorporates superior mechanical and electrical properties. From toughness to stiffness, in every criterion, this unmodified Nylon is one of the best construction materials. While contacting various chemicals, substances, etc., the decay of Nylon 101 is nearly zero.

This plastic material’s superiority does not end here. We know in-depth knowledge about this plastic is crucial for manufacturers, product designers, users, etc. Following this, we elaborate on Nylon 101 along with its properties, applications, advantages, and disadvantages.

Basics of Nylon 101

In 1935, DuPont’s Wallace Carothers invented Nylon 101. It is a polyamide. In the industrial world, it is well-known as PA 6/6. It is to be noted that this plastic type was known as Quadrant Nylon 101 in the earlier period.

How Nylon 101 Is Formed

In general, PA 6/6 is formed by the polymerization of Adipic acid and HMDA. This polymerization process also includes the removal of water. Another popular way to produce Nylon 101 for industrial use is the hydrogenation of 3-Nitrotoluene in the presence of the catalyst.

The catalyst type is determined in consideration of the desired outcome’s rigidity, toughness, and physical properties. Typically, the polymerization type is solid-state polymerization.

Properties of Nylon 101

The following are the various properties of this plastic material.

Mechanical Properties

The associated flexural strength is 15,100 PSI.

Physical Properties

Thermal Properties

Other Important Properties

Applications of Nylon 101

In this section, we list the most common and effective applications of Nylon 101.

Advantages & Disadvantages of Using Nylon 101

The following are the pros and cons of Nylon 101’s use.

Advantages of Using Nylon 101

Disadvantages of Using Nylon 101

Related Blogs

Looking for a trustworthy Supplier

Need a Trustworthy Supplier of Plastic, Foam, Sponge, Rubber, Metal, and Machining Solution. Click the Button, We Will Be In Touch With You As Quickly As Possible.