Acetal, Polyoxymethylene (POM) You Need To Know

Acetal, also known as polyoxymethylene (POM), polyformaldehyde, and polyacetal, is one of the engineering plastics. The density ranges from 1.41 to 1.5 g/cm3. It is mainly used for precision mechanical components, for example, gears, pulleys, rollers, bearings, housing parts, bushing, cams, valves, seals, gear wheels, and other parts with high stiffness, low friction, and excellent dimensional stability, low thermal expansion because acetal plastic offers high strength, hardness, and rigidity to −40°C.

Changing the ratio between acetal plastic and another material or annexing agent can obtain or enhance some special physical properties, such as higher toughness, flame retardant property, and electrostatic discharge (ESD).

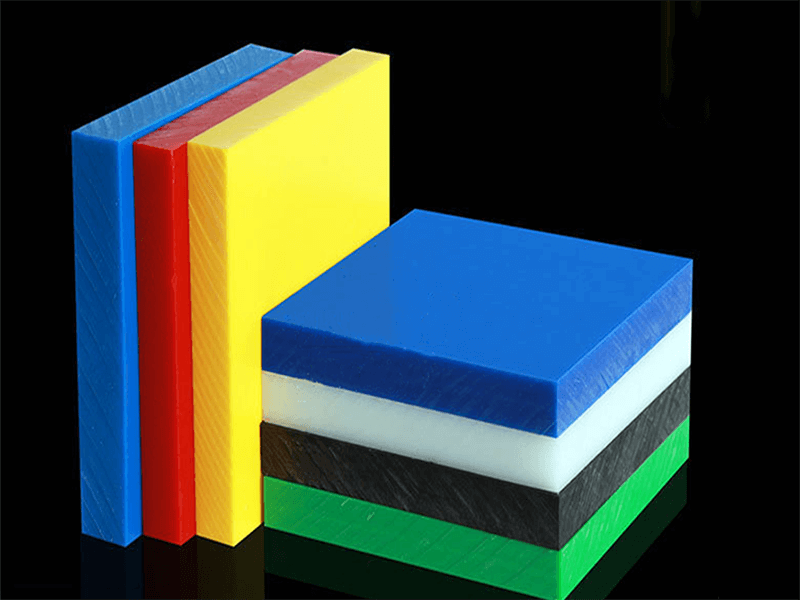

Acetal plastic’s natural color is intrinsically opaque white because of its high crystalline composition, but it can be produced in a variety of colors by adding colorant. Normally, Acetal or POM plastic is supplied in plastic granules and can be formed into the desired shape by heating and pressing. The common forming methods are injection molding and extrusion.

Specification of Acetal, Polyoxymethylene (POM) Plastic

Profile/Shape

Grade

Color

Custom Service

Acetal Sheet

Acetal Film

Acetal Rod

Acetal Tube

Custom Profile

Injection molding part

Remark

Properties of Acetal, Polyoxymethylene (POM) plastic

Main Usage of Acetal Plastic

Main Feature of Acetal Plastic

Industry

Can’t find what you need? Or Need custom Acetal/POM Plastic?

Leading Supplier of Acetal, Polyoxymethylene (POM) In China

As one of the leading suppliers of Acetal plastic (POM) in China, UVTECO provides all forms of POM, including Sheet, Rod, and Tube with different grade Homopolymer, Copolymer, PTFE filled, Glass-filled, Static Dissipative (ESD), UV Resistant, etc. Otherwise, UVTECO provides machining services, for example, cutting, CNC machining, lathe turning, drilling, injection molding, etc.

As an ISO-certified company, UVTECO stocks frequently used Acetal sheets, rods, and tubes for fast delivery, available in natural, white, and black colors. Meantime, we provide high-quality POM-based products and parts/components for more than 2500 clients from more than 45 countries, who are working in automation, the automobile industry, medical industry, food industry, aerospace industry, appliance industry, electrical & electronic, etc.

Contact UVTECO for machining Acetal/POM service

Related Blogs about Acetal/POM Plastic

Frequently Asked Questions about Acetal/POM Plastic

Looking for a trustworthy Supplier

Need a Trustworthy Supplier of Plastic, Foam, Sponge, Rubber, Metal, and Machining Solution. Click the Button, We Will Be In Touch With You As Quickly As Possible.