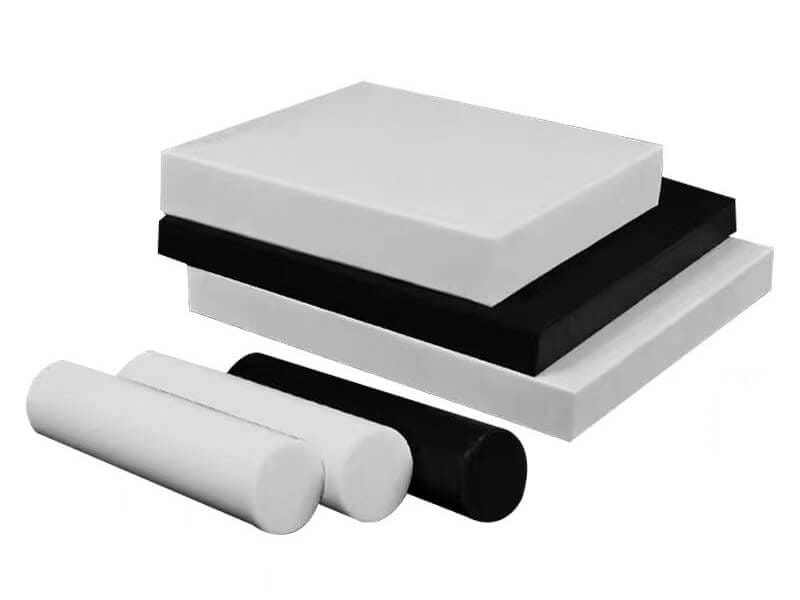

PET Plastic in all forms

PET Sheet, PET Rod, PET Tube, Custom Extrusion Profile, Injection Molding Part, Machining Service…About PET plastic

PET plastic is a short name for Polyethylene Terephthalate, therefore, some people call it “PET-P”. Although it has been called PET-P plastic for a long time, it is an outdated name. Nowadays, most people call it PET plastic.

PET plastic is a semi-crystalline engineering thermoplastic polyester. Its density is 1.38 g/cm³, which is relatively higher than most plastics. Compared to POM plastic, PET plastic offers excellent dimensional stability, low moisture absorption, and high strength. Therefore, it suits complex parts with high dimensional accuracy and surface quality requirements.

If a solid lubricant is inside, PET plastic can offer high wear resistance and a low coefficient of friction. It also offers outstanding thermal properties, such as good temperature and dimensional stability.

Specification about PET plastic

Grade

- Unfilled

- Lubricated

- PTFE Filled

- Food Grade

- PET-G

- PET-H

Profile/Shape

- Sheet

- Rod

- Film

- Tube

Color

- Nature (White)

- Grey (oil-filled)

- Transparent

- Black

- Blue

Custom Service

- Custom profile by extrusion;

- Custom part by injection molding;

- Custom part by CNC Machining;

PET Sheet

- Thickness: From 1mm to 100mm

- Width: from 500mm to 1000mm

- Length: from 610mm to 1220mm

PET Rod

- Diameter: From 2mm to 350mm

- Length: 1000 mm or custom

Custom PET part

- Custom extrusion profile;

- Custom injected molding shape;

Remark

- All sizes can be customized according to the requirements of clients;

- Machining services are available;

Properties of PET plastic

| Item | Description |

|---|---|

| Product name | PET Plastic (Polyethylene Terephthalate) |

| Available color | Nature (White), Grey (oil-filled), Black (), Green, Blue, Red, Yellow, Custom color |

| Density | From 1.39 g/cm3 to 1.44 g/cm3 |

| Flammability | HB/UL94 |

| Mechanical Properties | Testing Method | Unit | Value |

|---|---|---|---|

| Tensile yield strength | ASTM D638 | psi/MPa | 12300/85 |

| Tensile strain (elongation) at yield | ASTM D638 | % | 4 |

| Tensile strain (elongation) at break | ASTM D638 | % | 20 |

| Tensile modulus Elasticity | ASTM D638 | KSI | 460 |

| Compressive Strength | ASTM D695 | psi/MPa | 15000/103 |

| Izod Impact Notched | ASTM D256 | ft.lb/in | 0.5 |

| Flexural Strength | ASTM D790 | psi/MPa | 18000/124 |

| Flexural modulus Elasticity | ASTM D790 | KSI | 490 |

| Shore Hardness D | ASTM D2240 | 84 |

| Physical Properties | Testing Method | Unit | Value |

|---|---|---|---|

| Density | ASTM D792 | g/cc | 1.41 |

| Water absorption (Dipping in water at 23°C for 24 hours) | ASTM D570 | % | 5 |

| Thermal Properties | Testing Method | Unit | Value |

|---|---|---|---|

| Melting temperature | ASTM D3418 | °F/°C | 473/245 |

| Coefficient of Linear Thermal Expansion | ASTM E-831, Average value between -40 and 150°C | μin./in./°F | 33 |

| Heat deflection temperature | ASTM D648 | °F/°C | 230/110 |

| Max. continuous service temperature in Air | °F/°C | 212/100 | |

| Min. continuous service temperature in Air | °F/°C | -4/-20 | |

| Flammability | UL94 | HB |

| Electrical Properties | Testing Method | Unit | Value |

|---|---|---|---|

| Electric strength | IEC 60243-1 | KV/mm | 22 |

| Volume Resistivity | IEC 62631-1 | ohm.cm | 1014 |

| Surface Resistivity | ANSI/ESD STM 11.11 | ohm | 1013 |

| Dielectric constant at 1MHz | IEC 62631-2-1 | 3.2 | |

| Dissipation factor at 1MHz | IEC 62631-2-1 | 0.014 |

Main Usage of PET Plastic

- Bearings and washers;

- Electronic component housings;

- Pump and valve parts;

- Gears and gear housings;

- Packaging and machinery parts;

- Food processing machinery components;

- Connector housings;

- Stop block, rollers and grabbers;

- Wear pads;

- Sliding elements;

Main Feature of PET Plastic

- Excellent strength and stiffness;

- Outstanding wear resistance;

- Good machinability and dimensional stability;

- High rigidity and hardness;

- Low water absorption rate and good chemical resistance;

- Great strength retention up to 85° C;

- Excellent chemical resistance;

- Low moisture absorption;

- Low thermal expansion;

Industry

- Food processing industry;

- Packaging machine;

- Aircraft & Aerospace Industry;

- Semiconductor industry;

- Pharmaceutical industry;

- Tobacco processing machines;

- Electronic industry;

- Automotive industry;

- Medical industry;

- Mechanical engineering;

Can’t find what you need? Or have a technical question?

Leading Supplier of PET Plastic in China

UVTECO is a leading supplier of PET Plastic profiles, including PET Sheets, PET Rods, PET Tubes, custom PET extrusion profiles, and injected PET parts. We also provide machining services, and the typical processing methods include CNC Machining (three-axis and five-axis), Die-cutting, turning, injection molding, engraving, etc.

UVTECO usually stocks high-quality PET Plastic Sheets and rods in standard sizes for fast delivery to global clients. Today, UVTECO, an ISO-certified company, provides high-quality PET-based products/parts/components for over 2,500 clients in more than 45 countries.

Contact UVTECO for machining Rigid PVC Plastic

NEED HELP FROM ENGINEER FOR PLASTIC PARTS

If you need to submit files, please send email to info@uvteco.com

Related Blogs about PET Plastic

Process of Machining Nylon

By UVTECOPosted in Blogs About PlasticWhat is G10 Epoxy Sheet

By UVTECOPosted in Blogs About PlasticG10 Vs FR-4

By UVTECOPosted in Blogs About PlasticFR-4 Printed Circuit Board

By UVTECOPosted in Blogs About PlasticCNC Machining FR4 and G10

By UVTECOPosted in Blogs About PlasticNylon 101

By UVTECOPosted in Blogs About PlasticDigital Printing On Acrylic

By UVTECOPosted in Blogs About PlasticPlastic Sheet for Skylight

By UVTECOPosted in Blogs About PlasticPolypropylene Vs Acrylic

By UVTECOPosted in Blogs About PlasticPlastic Forming Process

By UVTECOPosted in Blogs About PlasticMachining Polyimide Plastic

By UVTECOPosted in Blogs About PlasticPETG Vs. Acrylic

By UVTECOPosted in Blogs About PlasticABS Plastic Property

By UVTECOPosted in Blogs About PlasticPainting Plastic Car Parts

By UVTECOPosted in Blogs About PlasticHow to Polish Polycarbonate

By UVTECOPosted in Blogs About PlasticPET injection molding

By UVTECOPosted in Blogs About PlasticNitrocellulose Vs PVDF

By UVTECOPosted in Blogs About PlasticPlastic for Signage

By UVTECOPosted in Blogs About PlasticWhat is PEEK plastic

By UVTECOPosted in Blogs About PlasticAcrylic Vs Polycarbonate

By UVTECOPosted in Blogs About PlasticDifference HDPE Vs PET

By UVTECOPosted in Blogs About PlasticDifference PVDF Vs PTFE

By UVTECOPosted in Blogs About PlasticPEEK Bushing and Bearing

By UVTECOPosted in Blogs About PlasticHow to Machine PEEK Plastic

By UVTECOPosted in Blogs About PlasticFood Grade Plastic

By UVTECOPosted in Blogs About PlasticDifference ABS Vs HDPE

By UVTECOPosted in Blogs About PlasticABS plastic Application

By UVTECOPosted in Blogs About PlasticABS Vs PVC

By UVTECOPosted in Blogs About PlasticMachining UHMW Plastic

By UVTECOPosted in Blogs About PlasticAcetal Vs Polypropylene

By UVTECOPosted in Blogs About PlasticHDPE Vs Acrylic

By UVTECOPosted in Blogs About PlasticHDPE Vs PVC plastic

By UVTECOPosted in Blogs About PlasticHDPE Vs ABS

By UVTECOPosted in Blogs About PlasticHDPE vs UHMW

By UVTECOPosted in Blogs About PlasticTeflon vs UHMW

By UVTECOPosted in Blogs About PlasticDelrin vs UHMW

By UVTECOPosted in Blogs About PlasticAcetal Vs. UHMW plastic

By UVTECOPosted in Blogs About PlasticWhat is Rapid Tooling?

By UVTECOPosted in Blogs About Plastic

Frequently Asked Questions about PET Plastic

PET has a high melting point, typically ranging from 256 to 260°C or 392 to 500°F. At 260°C, PET starts melting and deforming its structure. Since it can easily withstand higher temperatures, it can be used in applications where temperature resistance is important, such as food packaging, automotive parts, or electronics.

Different types of cutting tools like fine-toothed saws, rotary cutters, or laser cutters are used to cut the PET plastic. Before starting, you need to place the PET on a flat surface with solid support underneath it. Now, hold the sharp knife at a slight angle and start cutting the plastic. Make sure to put firm and steady pressure while running the knife. It ensures precise cutting without cracking or breaking during the process.

A PET plastic sheet is a solid structured sheet that is made from a special kind of polyester resin named PET. This plastic is highly known for its super physical and chemical properties. It is transparent, glossy, and resistant to microorganisms and chemicals. Besides, it works as a sturdy electric insulator as well as having low to zero hydrophobicity.

Yes, PET is a very strong and durable plastic. The superior physical and chemical properties make it heat and wear-resistant and prevent it from degrading. It has excellent dimensional stability, which is ideal for various high-stress applications. The plastic can withstand heavy use in industries like automotive, electronics, and packaging.

Yes, PET can easily be recycled. You can even recycle PET products over and over again and turn them into different forms like new sheets, rods, and tubes. Recycling happens in a few steps. First, it is cleaned to remove dirt and then ground into small pieces called flakes. Lastly, flakes are shortened by color and type so you can use them right away.

No, PET plastic is not biodegradable. Its high molecular weight and hydrophobicity make it difficult for microorganisms to break it down. Due to this, it takes a long time to decompose in nature. However, PET is fully recyclable, which lowers its environmental impact.

Yes, PET is in the range of safe and non-toxic plastic. It is widely used in food packaging, consumer goods, and industrial parts. Typically, PET doesn’t release harmful chemicals. That’s why it is a reliable material for industries where safety and stability are essential. Like automotive and electronics manufacturing.

You will find PET plastic used in different industries. Such as packaging, textiles, or automotive. Mostly you will find this plastic in food and beverage packaging like water bottles, soft drinks, juices, salad dressings, peanut butter, cooking oils, and so on. In the textile industry, the plastic is known as polyester.

Look for the recycling code “1” when considering the best PET plastic for your application. It is the Resin Identification Code, which should be stamped on the bottom of the packaging. This code identifies plastic that is tough, clear, and chemically resistant. It’s available in sheets, rods, and tubes.

Yes, PET offers better stability than PVC. It’s stronger, more wear-resistant, and easier to recycle. The high-grade thermal and chemical resistance properties make it ideal for demanding applications. On the other hand, PVC is used for less critical applications where high performance is not typically required.

PET is a durable plastic, and you can expect to use the PET plastic product for up to several decades. Its higher performance properties and resistance to wear and chemicals allow it to perform well for many years. However, the time it takes to degrade depends on several factors. Long exposure to UV radiation is one of them.

Yes, PET plastic can be glued, but it is difficult to work with some specific adhesives. Some of the adhesives that work on PET bonding are Permabond TA4600 series, Permabond POP, Permabond 105, Permabond 2050, and SuperTAC 500 Plastic Bonding Hot Melt Sticks. With these adhesives, it forms durable connections and makes a strong product used for industrial applications.

Yes, PET plastic can be injection molded. Its chemical resistance and low moisture absorption properties ensure effective molding and produce high-precision parts. Due to its high accuracy and consistency in the molding process, it is widely used to make automotive and medical components.

Yes, PET has good machinability and shows minimal resistance when machining. It can be easily cut, drilled, and shaped into precise parts. Its low friction and excellent wear resistance make it ideal for machining, especially in applications that require smooth surfaces and high-performance components.

No, PET is not UV resistant. So you can’t use it in outdoor applications. It absorbs UV waves with wavelengths between 300 nm and 330 nm. When exposed to light and air, it goes to photochemical aging, which degrades its upper surface. Due to long exposure, it loses its mechanical and thermal stability and deforms altogether.

The high-grade electrical insulating properties, wear, and chemical resistance make it a perfect go-to plastic solution for electrical applications. Mostly, it works as an insulator in electrical applications where it protects circuit safety by isolating current. Plus, PET has low water absorption, which means it effectively maintains its insulating properties even in humid environments.

Looking for a trustworthy Supplier

Need a Trustworthy Supplier of Plastic, Foam, Sponge, Rubber, Metal, and Machining Solution. Click the Button, We Will Be In Touch With You As Quickly As Possible.