Teflon Vs. UHMW: Exploring the Battle of High-Performance Polymers

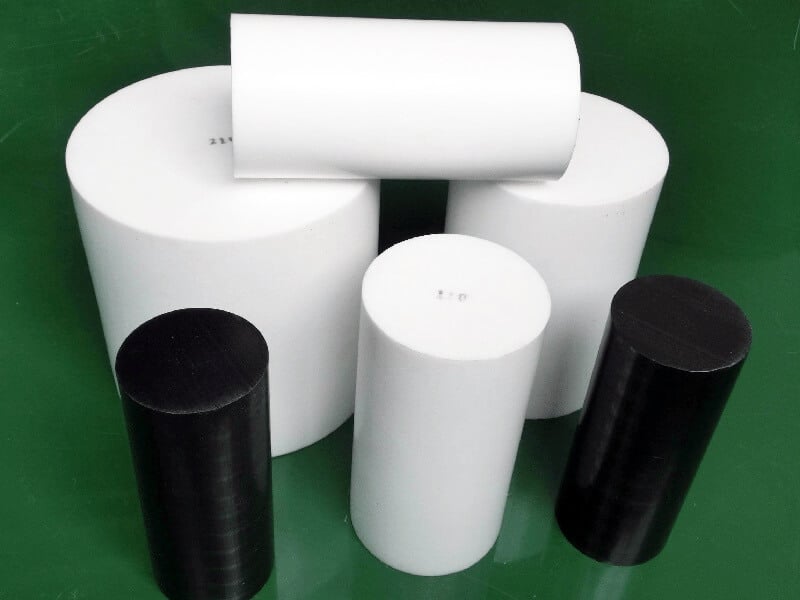

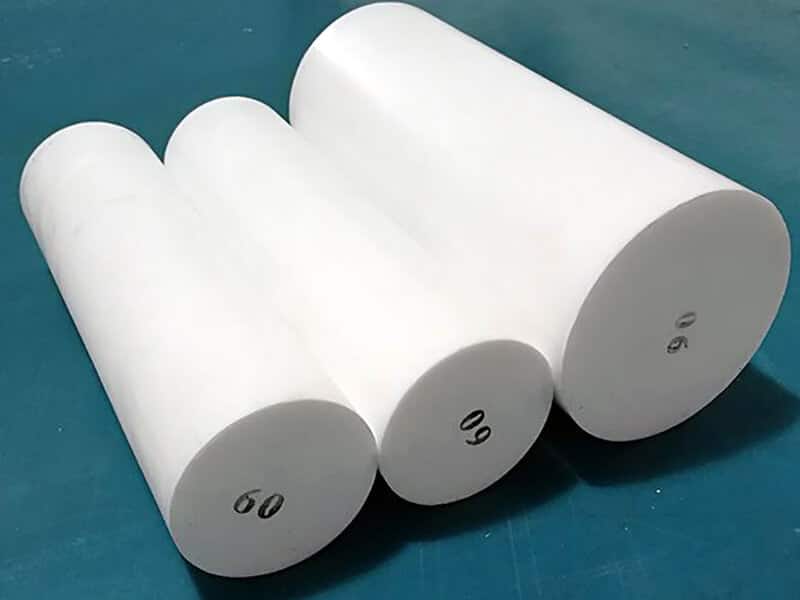

UHMW (ultra-high molecular weight polyethylene) and Teflon, a brand name for PTFE (Polytetrafluoroethylene), are smooth, white plastics.

Both can come into close contact with food and don’t soak up water. Teflon and UHMW are also very resistant to the cleaning solutions and lubricants commonly used in conveyors and packing machines. This is the last point where they are the same.

Teflon: Everything you need to know

Teflon, or PTEE (Polytetrafluoroethylene), is a soft fluoropolymer with low friction that is resistant to chemicals and the weather. PTFE is stable up to 500 ° F and is often used in places where temperatures are high. PTFE is also very good at keeping electricity from going through it.

Common Characteristics of Teflon

Teflon is made up of molecules of tetrafluoroethylene that repeat. Single bonds hold the carbon atoms together, and each fluorine atom is joined to a carbon atom. This makes a chain of carbon atoms where every other carbon atom is bound to a fluorine atom. Weak Van der Waals forces hold this chain together. Some other characteristics are:

Common Applications of Teflon

Advantages of Teflon

Using Teflon has a lot of advantages. Some of the benefits are:

Disadvantages of Teflon

UHMW: Everything you need to know

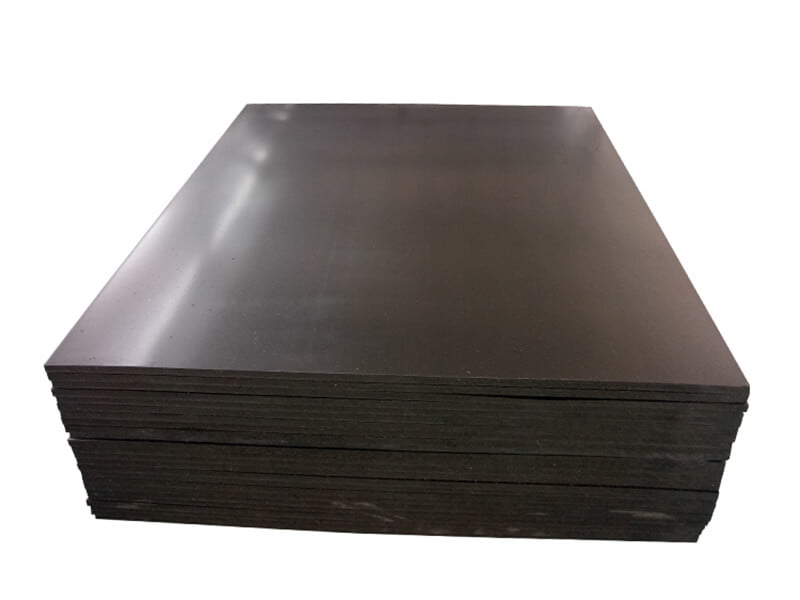

UHMW means “Ultra High Molecular Weight Polyethylene.” “Ultra High Molecular Weight Polyethylene” is the name for polyethylene with a molecular weight of 3.1 million or more.” This material that can be cut with a machine is known for being very tough, resistant to wear, and having a very low coefficient of friction. It also has a high impact strength and is very immune to chemicals.

UHMW is a great all-purpose material because it can be used in almost any setting and has many different properties.

Common Characteristics of UHMW

Common Applications of UHMW

Advantages of UHMW

Ultra-high molecular weight (UHMW) plastics that are affordable and immune to abrasion. Some of the advantages of UHMW are:

Disadvantages of UHMW

Comparison Between Product Teflon Vs. UHMW

| Type | Teflon | UHMW |

|---|---|---|

| Short description | Teflon is made of a flexible polymer. At room temperature, it is a white solid weighing about 2.2 g/cm3. | Ultra-High Molecular Weight (UHMW) is an industrial polymer that has a different average molecular weight, with a average chain length than high-density polyethylene (HDPE). |

| What ingredients were used to make this | There are also worries about its safety and environmental impact. There may be better choices for some uses. | Thermoplastic polyethylene includes ultra-high-molecular-weight polyethylene (UHMWPE or UHMW). UHMWPE doesn’t smell, taste, or hurt you in any way. |

| applications | It is used to make pots and pans that don’t stick. It is used to make something that reduces friction. | UHMW is often used to make gears, belt scrapers, chain guides, idler wheels, sprockets, and parts for packaging machines. |

| characteristics | At room temperature, it is a solid that is white. It takes 600 K to melt. | UHMW is rugged, smooth, and long-lasting, and it has a high tensile strength. |

| Pros | Its low friction, ability to not stick, resistance to heat and chemicals, and resistance to chemicals. | There are also worries about how safe it is and how it affects the environment. There may be better choices for some uses. |

| Cons | UHMW is more potent, lasts longer, wears better, and works better in challenging situations than other materials. | Because of its thermal instability, it might not be the best material for making things that need to be very precise. |

Final Words

Although Teflon and UHMW can be used for the same application in many fields, they offer different characteristics. If you don’t know how to choose a suitable material, please contact UVTECO.

Related Blogs

Looking for a trustworthy Supplier

Need a Trustworthy Supplier of Plastic, Foam, Sponge, Rubber, Metal, and Machining Solution. Click the Button, We Will Be In Touch With You As Quickly As Possible.