About UHMW Plastic

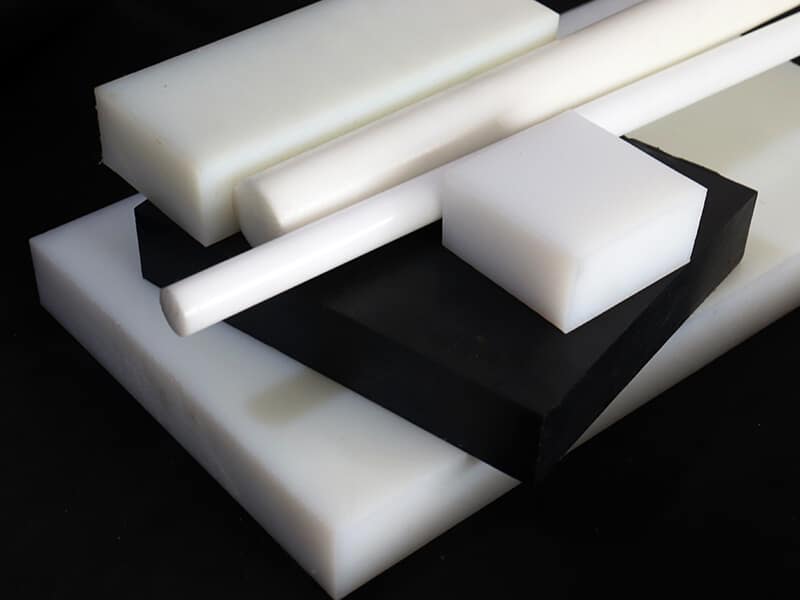

UHMW or UHMW-PE, full name is Ultra-high Molecular Weight Polyethylene, It is one of the most popular engineering plastics, some people call it “PE1000”. The molecular weight ranges from 3.5 million to 100 million grams per mole. UHMWPE plastic is tasteless, nontoxic, and odorless. It is a highly cost-effective engineering plastic with excellent comprehensive physical properties, including toughness, wear resistance, and chemical resistance.

Compared with HDPE (high-density polyethylene), UHMW plastic has all the characteristics of HDPE. It offers the enhanced capability to be resistant to concentrated acids, alkalis, numerous organic solvents, and oxidizing acids. It is self-lubricating and has extremely low moisture absorption and a very low coefficient of friction, in some forms being 15 times more resistant to abrasion than carbon steel.

Compared with Nylon and Acetal, UHMW plastic has a significantly lower coefficient of friction. And comparing with PTFE or Teflon (polytetrafluoroethylene), UHMW plastic has better abrasion resistance.

UHMW-PE plastic works well from -40°C to 80°C (from -40°F to 176°F). The extrusion process produces sheets, rods, tubes, and special profiles, which can easily be fabricated and machined into UHMW parts by CNC machining centers, turning lathes, milling machines, etc.

Specification about UHMW Plastic

Profile/Shape

Grade

Color

Production process

UHMW sheet

UHMW Film

UHMW Rod

UHMW Tube

Custom Profile

Remark

Properties of UHMW Plastic

Main Feature of UHMW Plastic

Main Usage of UHMW Plastic

Main Industry

Can’t find what you need? Or need a custom UHMW PE?

Leading supplier of UHMW Plastic and machining service

Since 2003, UVTECO has begun to be active in UHMW Plastic by machining UHMW Sheets/Rods/Tubes. We know more about UHMW plastic, including raw materials, additives, production processes, machining solutions, etc. With unremitting efforts, we have become a leading supplier of UHMW Sheets/Rods/Tubes/Films in China.

We stock the frequently used UHMW sheets/rods/tubes/films for fast delivery to global clients. In the meantime, UVTECO provides integrated machining solutions for UHMW-based parts/components. The main machining methods include cutting, 3-axis and 5-axis CNC milling, CNC Turning, injection molding, thermal forming, engraving, etc.

Today, UVTECO provides high-quality UHMW parts/components for over 2,500 clients from more than 45 countries. They are active in aerospace, agriculture, food, beverage, medical industry, mining industry, Oil & Gas industry, etc,

Contact UVTECO for machining UHMW PE Plastic

Related Blogs about UHMW PE Plastic

Frequently Asked Questions about UHMW PE

Looking for a trustworthy Supplier

Need a Trustworthy Supplier of Plastic, Foam, Sponge, Rubber, Metal, and Machining Solution. Click the Button, We Will Be In Touch With You As Quickly As Possible.