Understanding G10 and FR-4 Glass Epoxy_ Essential Properties and Applications

Learn about G10/FR-4 glass epoxy, its essential properties, and versatile applications in electronics, aerospace, and industrial manufacturing.

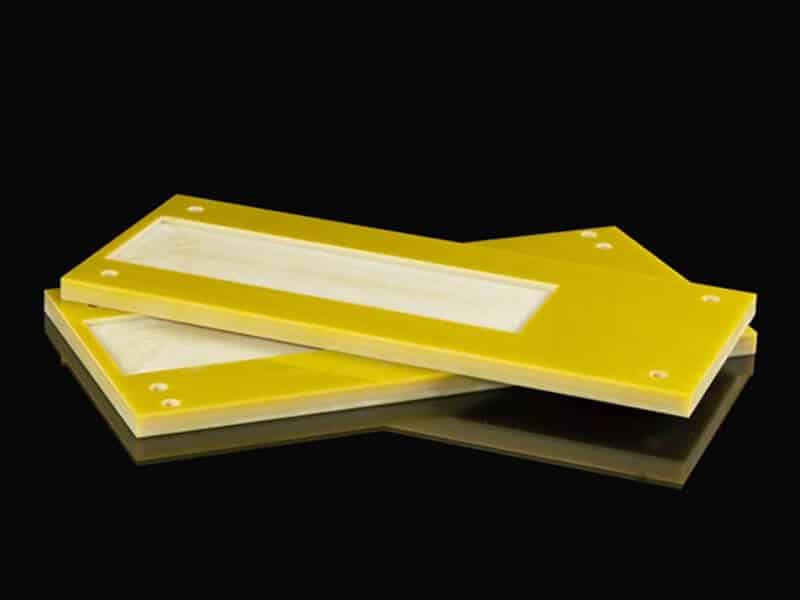

G10/FR-4 epoxy glass remains a staple material in modern engineering. It combines woven fiberglass with epoxy resin to create a strong component. This versatile laminate is transforming everything from electronics to aerospace applications through its outstanding combination of strength and insulating properties; while industrial Development continues and beyond, the G10/FR-4 continues to be essential for innovative design and manufacturing solutions.

Essential Properties of G10/FR-4 Glass Epoxy

The combination of a wide range of properties makes G10/FR-4 epoxy glass versatile and suitable for using in different applications for various industries.

Mechanical Properties

G10/FR-4 has excellent mechanical strength and dimensional stability. Having a tensile strength of 275-540 MPa and a flexural strength of about 380-480 MPa, the structural integrity is excellent. It maintains its shape under compressive stress with a compressive strength of about 415 MPa. Its great resistance to wear and low moisture absorption of about 0.1% ensure long-term reliability.

Electrical Properties

As an efficient electrical insulator, G10/FR-4 boasts notable dielectric properties. It maintains a dielectric electricity of 20 kV/mm and a dielectric constant of four. 8 at 1 MHz, making it ideal for electrical packages. The fabric’s volume resistivity exceeds 10^16 ohm-cm, making sure of regular performance in electronic additives. Its low dissipation is zero. 02 at 1 MHz, which minimizes strength losses in excessive-frequency applications.

Thermal Properties

G10/FR-4 demonstrates remarkable thermal stability across a wide temperature variety. With a warmth deflection temperature of one hundred forty°C and non-stop working temperature functionality up to one hundred thirty°C, it maintains its structural integrity underneath thermal strain. Its low thermal enlargement coefficient (X-Y axis: 14-17 ppm/°C) ensures dimensional stability through temperature fluctuations.

Chemical Resistance

The material exhibits excellent resistance to numerous chemical environments. It successfully withstands publicity to oils, fuels, and plenty of solvents without degradation. Its moisture resistance prevents delamination in humid situations, while its flame-retardant properties (UL ninety-four V-zero rating) make it suitable for packages requiring fireplace safety compliance. The material additionally resists salt spray and weathering, extending its provider life in harsh environments.

Common Applications of G10/FR-4 Glass Epoxy

G10/FR-4 glass epoxy is applied in many industries because of its versatility and durability. Some of the most common applications of this composite material are given below:

Electronics and Electrical Components

G10/FR-4 is considered the backbone of the electronics industry because it is mainly used as a base material for printed circuit boards. It finds ideal use in multilayer boards for computers, smartphones, and telecommunications equipment due to its excellent electrical insulation and dimensional stability. The material is also widely used in transformer parts, terminal boards, and switchgear components where reliable electrical insulation is crucial.

Industrial Applications

In industrial settings, G10/FR-4 is widely used in machine components and structural components. It’s generally employed in electrical panels, bushings, washers, and gaskets. The fabric’s excessive mechanical power and chemical resistance make it perfect for industrial tooling, gears, and wear strips. Manufacturing facilities utilize G10/FR-4 for conveyor components and meeting line elements wherein precision and durability are critical.

Aerospace and Defense

Aerospace and defense applications utilize G10/FR-4 for its extremely high strength-to-weight ratio and dependability. It is utilized for aircraft interior panels, radar components, and missile guidance systems. The material’s low moisture absorption and thermal stability allow it to function well at high altitudes. G10/FR-4 is also used in military communication devices and protective housings for sensitive electronic equipment.

Marine and Outdoor Applications

G10/FR-4’s resistance to water and harsh environments makes it suitable for offshore applications, in boat hulls, boat parts and underwater camera housings. This material retains its properties even after prolonged exposure to the sea. This makes them useful in offshore equipment and marine navigation systems. Its weather resistance also makes it suitable for exterior powder coatings and structural aids.

Recreational Equipment

In the sporting goods industry, G10/FR-4 is popular for its durability and performance. Used for knife handles, arrowheads, and the thickest parts of fishing gear. Skateboard manufacturers use it for fixing the plates. While snowboard and ski manufacturers bundle them with harnesses. This material is impact resistant and lightweight. This makes it ideal for protectors and equipment holders.

Comparison with Alternative Materials

Cost-effectiveness

G10/FR-4 provides a balanced cost in the market. This is despite a higher initial cost than traditional materials such as aluminum or phenolic alloys. But long service life and minimum maintenance requirements often result in lower life cycle costs. For example, a G10/FR-4 circuit may cost 20-30% more than an FR-2, but its performance And the circuit’s robustness justifies the investment for critical applications.

Performance Metrics

In terms of performance, the G10/FR-4 offers excellent quality in many areas. Its dielectric strength is higher than others, making it a good choice for electrical applications. Although carbon fiber composites have a high strength-to-weight ratio, G10/FR-4 offers outstanding electrical insulation and ease of handling. compared to aluminum It has better corrosion resistance and is lighter in weight. Even though it absorbs little heat.

Environmental Considerations

The environmental impact of G10/FR-4 presents both benefits and challenges. In contrast to pure thermoplastics, the nature of G10/FR-4s makes them more difficult to cycle. However, their outstanding durability means fewer replacement parts and reduced wear over time. Modern manufacturing processes have introduced halogen-free formats, which address concerns about traditional fireproof helmets.

Durability Comparison

The durability of the G10/FR-4s stands out among its alternative materials. While stainless steel offers better absolute strength, G10/FR-4 offers superior resistance to chemical corrosion and electrical interference. Compared with polyamide composites, it shows better dimensional stability under temperature changes. This material is superior to phenolic composites in terms of bending resistance and mechanical strength. Although phenols provide nutritional benefits for areas with less need.

Wrapping Up

G10/FR-4 offers a unique combination of strength, insulation and durability for various applications. This makes them irreplaceable in modern production. Although there are other options. But its proven versatility and cost-effectiveness continue to make it the preferred material for demanding applications around the world.

UVTECO is a leading supplier of G10 or FR-4 epoxy sheet in China, provides sheet, rod and tube. If you are looking for a trustworthy supplier of G10 or FR-4, Contact UVTECO now!

Related Blogs

Looking for a trustworthy Supplier

Need a Trustworthy Supplier of Plastic, Foam, Sponge, Rubber, Metal, and Machining Solution. Click the Button, We Will Be In Touch With You As Quickly As Possible.