ABS Plastic: Exploring Its Wide Range of Uses

Unlock the potential of ABS plastic! Explore its wide-ranging applications, from everyday items to industrial solutions.

ABS plastic is undoubtedly the most successful engineered thermoplastic. It comes in versatile colors and necessary features. Most importantly, this plastic is strong, durable, flexible, chemical resistant, impact resistant, shock resistant, and moisture resistant, making it suitable for versatile applications. Here, we gathered how versatile ABS plastics are and explored their wide range of usability.

Versatile ABS plastic Applications

Here are the most popular applications that use ABS plastic sheets for their products and equipment.

Computer Parts

ABS plastics have a good reputation for shock resistance. This plastic material is also lightweight but strong enough to survive in rough conditions. That is why computer parts like monitor cases, mouse frames, keyboards with keys, laptop cases, fans, CPU casing, etc., are made with ABS plastic.

Most of them are manufactured using injection moulding and 3D printing. However, ABS plastic has a strong electricity isolation capability, making it suitable for electronic devices like computer parts.

Medical Equipment

The biocompatibility of this plastic is the main reason for its high usability in medical sectors. ABS plastic is usually an engineered thermoplastic, which means it is made for different applications in a compatible environment.

However, ABS plastics are strong, thermal compatible, and don’t react while coming in contact with human tissue and fluid. So, manufacturers use this plastic for medical devices and equipment like syringes, valves for ventilators, tendon prostheses, drug-delivery systems, tracheal tubes, non-absorbable sutures, masks, etc. In addition, ABS plastic has the chemical and mechanical advancement to withstand gamma radiation and ethylene oxide.

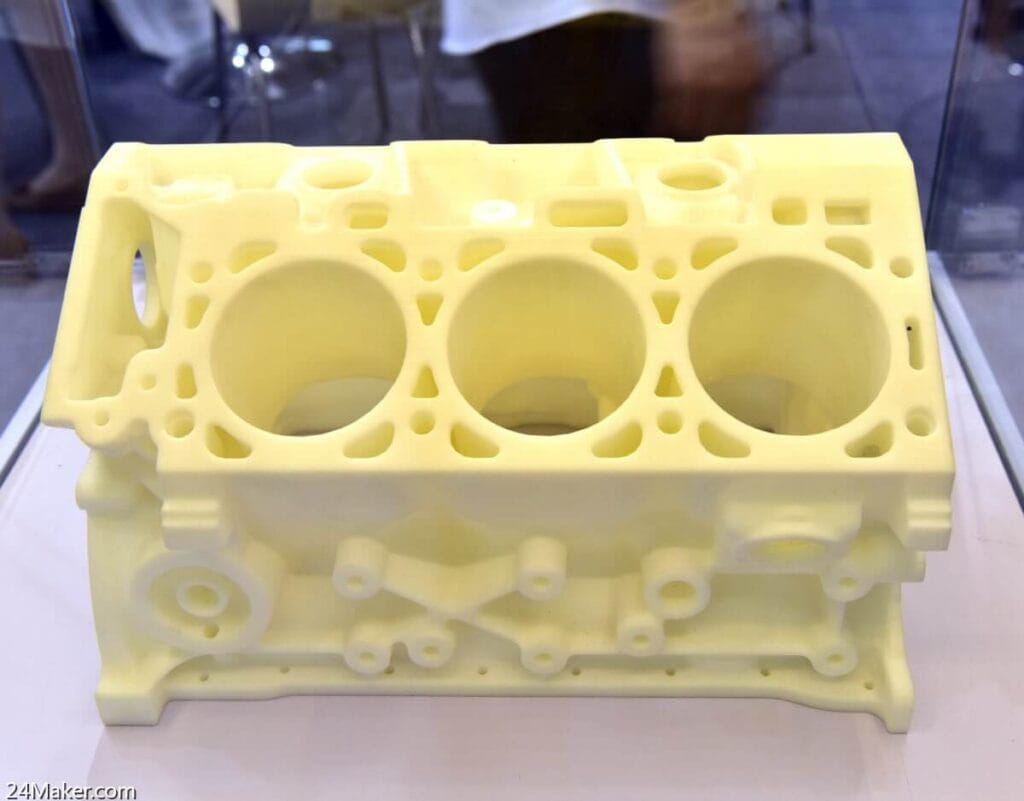

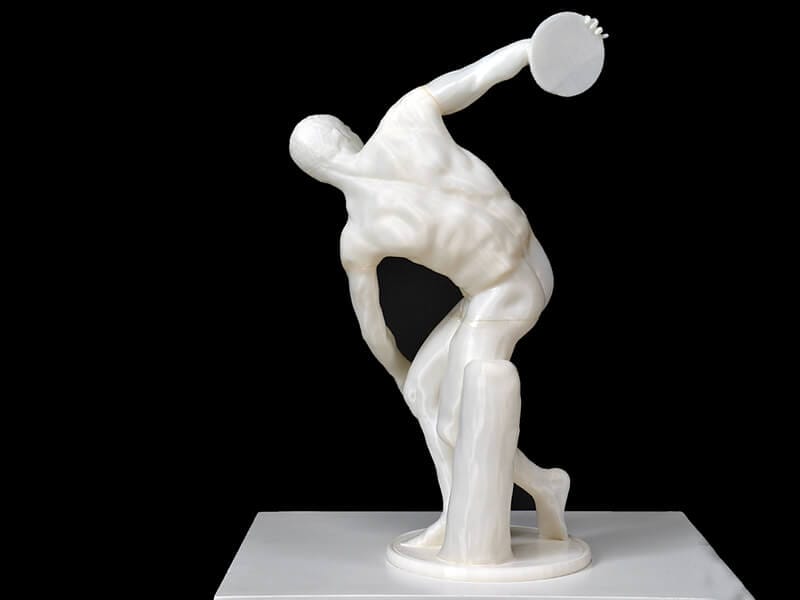

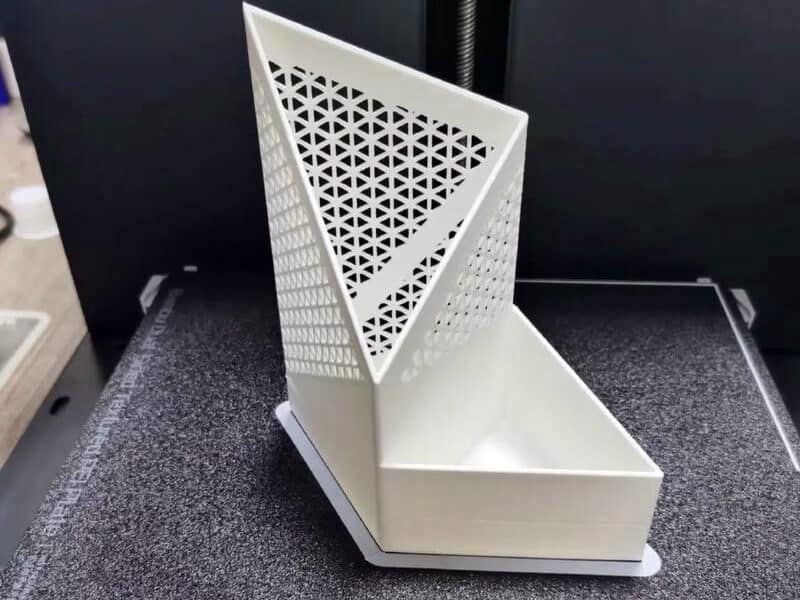

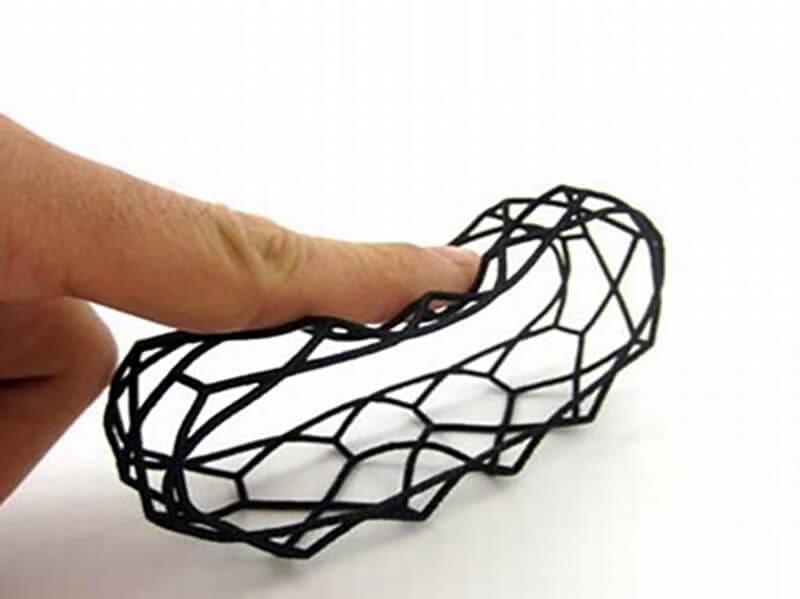

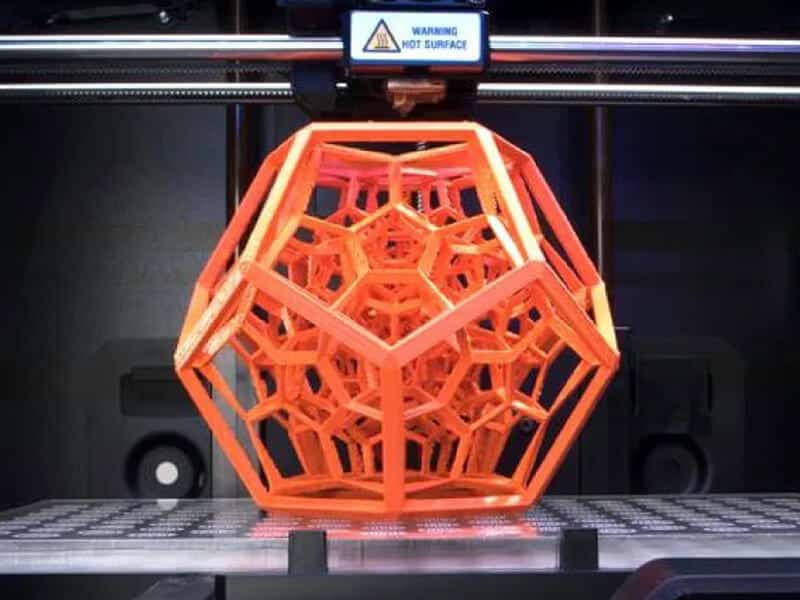

3D Printing Objects

ABS plastic is flexible and durable. It is kind of a soft but strong material. It comes with different colours that make it versatile and suitable for home-based 3D printing projects. However, plenty of plastics are suitable for 3D printing but the ABS material has exceptional benefits.

Considering the flexibility, craftspeople called it Lego plastic. On the other hand, ABS plastic materials maintain the precise geometry of the product. That’s one of the most important parts of using ABS plastics in 3D printing to make toys, vases, sticks, stickers, jewellery, prototypes, etc.

Automotive Parts

The ABS thermoplastic is mechanically strong with lightweight features. This material possesses a good quality of sturdiness with shock resistance that makes it suitable for withstand extreme pressure. Those qualities qualify ABS as the better choice for making automotive parts.

However, manufacturers use this plastic to create most of the interior of a vehicle. It’s easy to create different colour parts with desired capabilities with precise geometrical dimensions. Therefore, car parts like handles, seat backs, seat belt components, instrument panels, door loners, car lamp housings, chassis, pillar trim, and dashboard components are proudly made with ABS thermoplastic.

Aerospace Components

While we are going to talk about aerospace components, we have to consider the feature of solidity with vibration or electric resistance and anti-cracking. ABS thermoplastic is engineered with different components to withstand those possible threads that the aeroplane may face.

For instance, aircraft interior components and the cabin metal covering are made with ABS plastic sheets. Those sheets protect the interior in many tough situations. However, every aircraft has so many plastic components, and most of them are made with strong and durable plastics like ABS Plastic.

Household Items

Plastic has a wide range of popularity in household items. Every house has plenty of kitchen components that are made of plastic. However, ABS plastic has several properties that meet the requirements for becoming a household product.

In that case, household products need to be multiple-drop surviving and shock-resistant. Therefore, plastic items meet all the requirements. The ABS thermoplastic provides durable household items including bed covers, nuts & boots for TV mounting, toys, furniture, washing machine casings, etc.

Electronic Items

As we know ABS plastic material is good with electric insulations. That means it is not conductive with an electric connection. That made it the ideal material for making electrical components. Nowadays, every electrical application uses thermoplastics like ABS to provide safe and durable service.

However, plenty of electrical equipment is made with this plastic including electric circuit holders, switches, connectors, wire covering, phone casings, printer casings, handheld device casings, speaker casings, etc.

Consumer Equipment

This thermoplastic has a reputation for impact resistance and durability. It also prevents chemical contamination and provides stiffness. Therefore, ABS plastics are used in many consumer equipment including food packaging, luggage, metal covering, toys, electronic housing, laptop stands, mobile casings, food supply packing, control panels, vacuum cleaners, shavers, refrigerator liners, etc.

As we know consumer products have some regulations that need to be maintained like biocompatibility. In that case, ABS doesn’t do chemical reactions while in contact with the human tissue. So, consumer equipment like food packing is safe with ABS thermoplastic.

Office Supplies

ABS plastic is getting popular for office supplies for its versatile colour migration and design capabilities. It not only increases the decoration possibilities but also provides the necessary equipment. However, office supplies like date stamps, mobile holders, mobile covers, strip staplers, memorizers, notebook covers, pen holders, table accessories, calculators, furniture, etc are made with colour-customised ABS thermoplastic.

Therefore, ABS plastics are lightweight, strong, impact resistant, and better surface finishing capable. Those features made it suitable for small items that are used as office supplies.

Building Supplies

The construction industry is a huge market for plastic items. In that industry, concrete and wood are side by side but a plastic item keeps them together. However, this industry needs strong equipment that can withstand extreme impact and survive UV rays with rough environmental conditions.

For instance, ABS thermoplastic meets the requirements of stability and durability. Nowadays, however, building doors, window frames, pipe fittings, plumbing items, etc., are made with impact-resistant ABS thermoplastic.

Sports Equipment

ABS plastic is super moldable, has precise geometry, and is lightweight. That means it can be used in the sports industry to make rackets, bats, jet skis, boots, safety pads, nets, bicycles, helmets, guards, kits, etc.

Therefore, sports equipment has versatile colour requirements that ABS easily meets. This thermoplastic can make an outstanding entry for its great impact resistance and shock resistance ability. Also, it can perform to its best in unwell environmental conditions.

Marine Equipment

In the marine industry, it is important to be moisture-resistant, impact-resistant, and chemical-resistant. ABS thermoplastic covers all the requirements with top-class performance. Despite the versatility, this thermoplastic provides better safety from rough weather and UV rays.

It can be used in the metallic parts of the yacht. It increases the aesthetic appeal with its strong knitting and colour customization ability. However, ABS plastic is used in the marine industry to make interior components like the dashboard, handles, steering, cabinets, seats, etc. It also provides up to 1000 lbs screw retention.

Final Word

Plenty of plastics are introduced to us in many industries. ABS is one of them, with so many possibilities. Continuous research is expanding the possibility of manufacturing a wide range of applications. Some manufacturing experts have pointed out that plastic is the future.

If you are looking for a trustworthy supplier of ABS parts, you can contact UVTECO, which is an expert in engineering ABS plastic in China.

Related Blogs

Looking for a trustworthy Supplier

Need a Trustworthy Supplier of Plastic, Foam, Sponge, Rubber, Metal, and Machining Solution. Click the Button, We Will Be In Touch With You As Quickly As Possible.