The Difference PETG Vs. Acrylic

PETG’s full form is Polyethylene Terephthalate Glycol. It is a versatile and widely used thermoplastic polymer. PETG is popular for its exceptional balance of strength, clarity, and ease of fabrication. On the other hand, Acrylic is a thermoplastic homopolymer. Its short form is PMMA. This material is widely used for enhanced weather resistance, chemical resistance, and appealing look.

Understanding the context of PETG vs. Acrylic assists professionals in material selection, evaluating product performance, and overall project success. The knowledge of the differences between these two materials allows the opportunity to get cost-effective solutions that embrace durability, design flexibility, etc.

PETG: Everything You Need to Know

In 1941, two British scientists named John Whinfield and James Dickson invented Polyethylene Terephthalate. Later on, after several kinds of research on this material, PET was glycosylated, producing Polyethylene Terephthalate Glycol, i.e., PETG.

PETG, the improved version of PET, is produced by the mixing of ethylene glycol and cyclohexane dimethanol. In this case, a two-page metal polycondensation process is involved. In the process, ethylene glycol and cyclohexane dimethanol are melted and blended. Then a bit of water is added to get the PETG. This stops PETG from forming crystals, which is different from PET.

Common Characteristics of PETG

The following are the core characteristics of PETG.

Common Applications of PETG

Below are the most common applications of PETG

Advantages of PETG

Here, we list the competitive benefits of using PETG.

Disadvantages of PETG

Below are the issues with this construction material.

Acrylic: Everything You Need to Know

Acrylic plastic was developed in the year of 1901 by a German chemist named Otto Röhm. Röhm innovated the process of polymerization methyl methacrylate producing Polymethyl Methacrylate, i.e., Acrylic. However, its commercial production started in 1933 in the name of “Plexiglas” In the USA, Plexiglas was patented in the 1930s by E.I. DuPont de Nemours & Company.

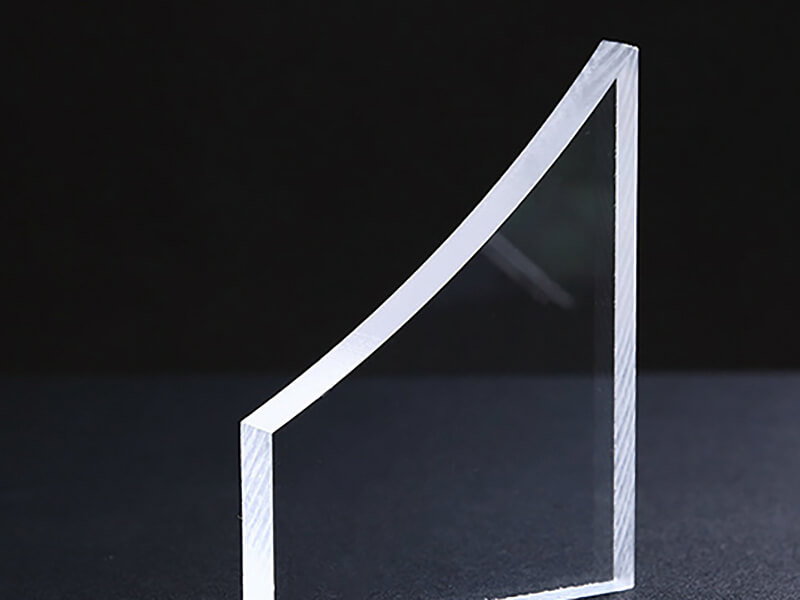

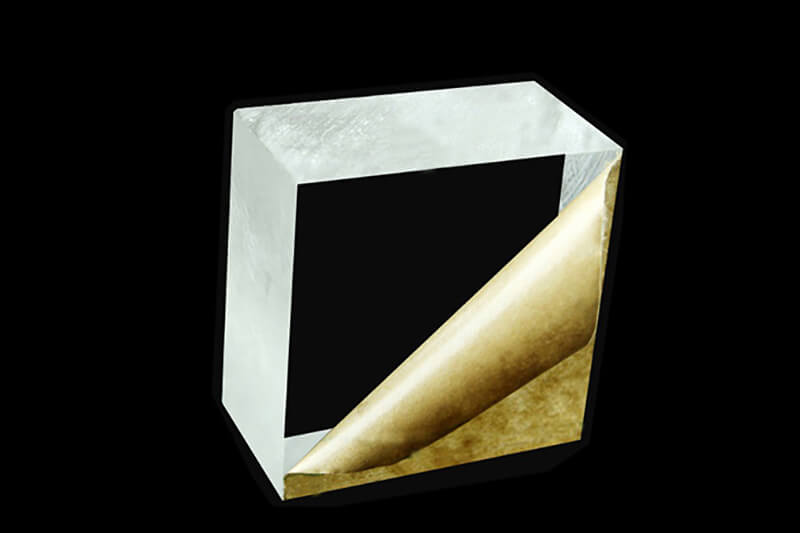

In general, a bulk polymerization process is used to produce Acrylic. In this process, methyl methacrylate and catalysts like organic peroxide are placed in a mold. Then, the mold is sealed to impose controlled heating. Due to the in-mold chemical reaction, Acrylic is formed.

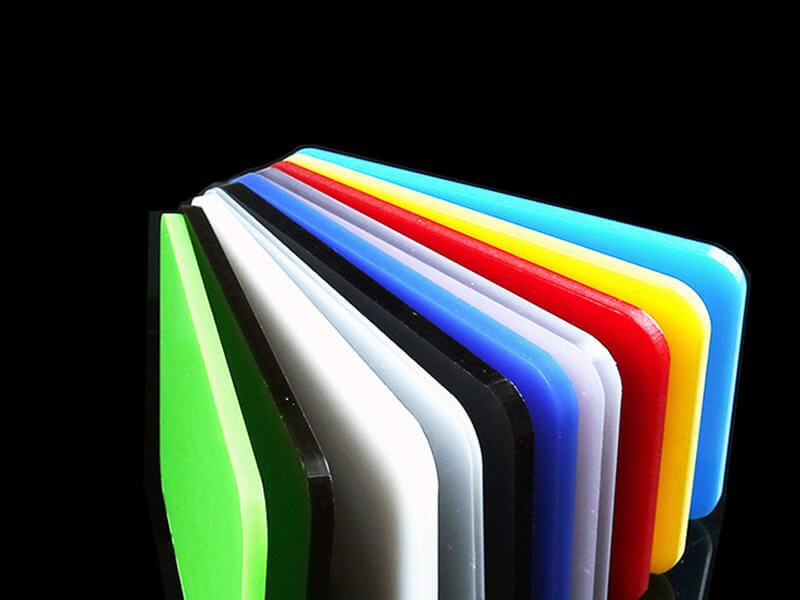

Common Characteristics of Acrylic

The following are the base properties of Acrylic.

Common Applications of Acrylic

Here we list the most popular applications of this material.

Advantages of Acrylic

The following are the competitive advantages of using Acrylic.

Disadvantages of Acrylic

The issues with Acrylic are listed below.

Comparison Between PETG Vs. Acrylic

| Type | PETG | Acrylic |

|---|---|---|

| Short description | PETG’s full form is Polyethylene Terephthalate Glycol. It is a thermoplastic polymer. | Acrylic is known as Polymethyl Methacrylate. It is a thermoplastic homopolymer. |

| What ingredients used to make this | Ethylene glycol and cyclohexane dimethanol | Methyl methacrylate, catalyst |

| Applications | PETG is used for 3D printing, windows, ad displays, food packaging, beverage bottles, etc. | Acrylic is used in producing furniture, canopies, lenses, LCD displays, paints, etc. |

| Characteristics | It offers enhanced thermal stability and easy fabricability. It is recyclable. | Impact, weather, and UV resistance. Lightweight. Easy to process. |

| Trade Name | Spectar, etc. | Crylux, Hesalite, Plexiglas, etc. |

| Price | Per M. Ton PETG price ranges from $725 to $890. However, the price varies significantly depending on brand, quality, etc. | Per Ton price is $900 to $1,200. |

Final Words

Although PEGT and Acrylic are transparent plastics, they offer different performances and are used in different applications.

UVTECO is a leading supplier of PETG and Acrylic material, sheets, rods, and tubes in China. We know more information about PETG, acrylic, and machining solutions. If you are looking for a trustworthy for your project, contact us now!

Related Blogs

Looking for a trustworthy Supplier

Need a Trustworthy Supplier of Plastic, Foam, Sponge, Rubber, Metal, and Machining Solution. Click the Button, We Will Be In Touch With You As Quickly As Possible.