ABS Vs. Acrylic – Choosing the Right Plastic

Discover the key differences between ABS and acrylic plastics and make an informed decision for your specific needs.

ABS and Acrylic plastic are fine materials built for durability and optimum performance. But when shopping for plastic, you have to know the right properties and applications of each one to ensure you are getting the right material for your individual needs.

Understanding the properties, advantages, disadvantages, and applications of these materials will enable you to make an informed decision and ensure you are getting the most out of your investment.

In this article, we will discuss the details of both items so you don’t have to make a decision in confusion. Whether you are working on a recreation, industrial, or personal project, this article will empower you to make the right decision by choosing the right material.

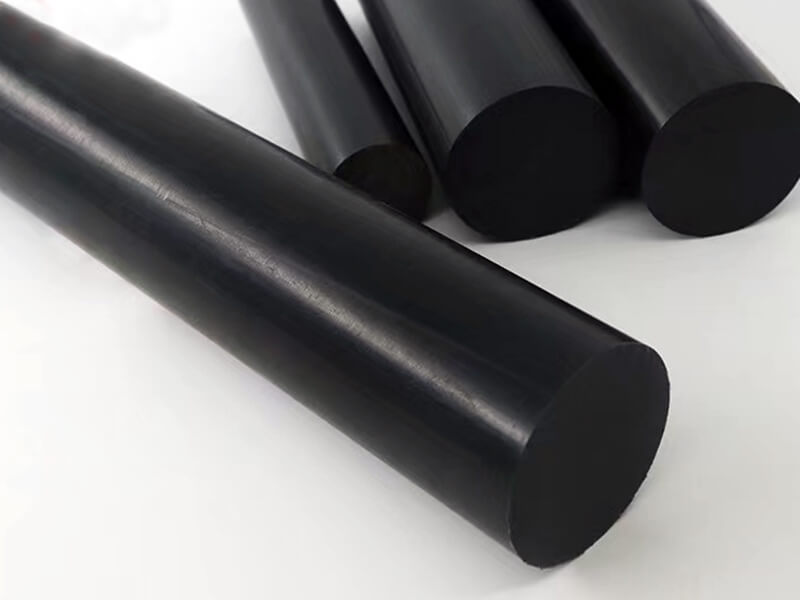

ABS Plastic: Everything you need to know

ABS is the short form of Acrylonitrile Butadiene Styrene. As the name suggests, this plastic is made from acrylonitrile, butadiene, and styrene.

The combination of these three great materials makes ABS one of the best kinds of plastics in the market, suitable for a wide range of applications and industries. So whether you are looking for industrial, artistic, or other needs, ABS can be a perfect fit, based on what you are looking for in the material.

Common Characteristics of ABS plastic

Here are some common characteristics or properties of standard ABS plastic:

Common Applications of ABS Plastic

Due to its wide range of great properties and characteristics, ABS plastic has numerous applications in various industries.

Advantages of Using ABS Plastic

Disadvantages of using ABS Plastic

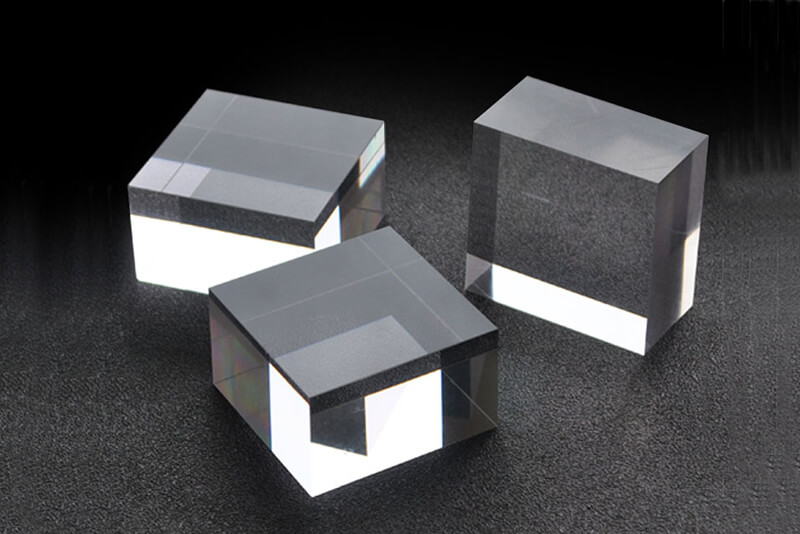

Acrylic plastic: Everything you need to know

If you read this article, you probably already know about acrylic plastic. Acrylic plastic is a common plastic material used in many applications indoors and outdoors.

For various reasons, acrylic, or polymethyl methacrylate, is a common choice among users and manufacturers. These plastics are known for their optical clarity, high impact resistance, and versatility to name just a few of their great properties.

These lightweight, light-transmitting, weather-resistant, and UV-protective qualities make them a great choice for industrial and household applications.

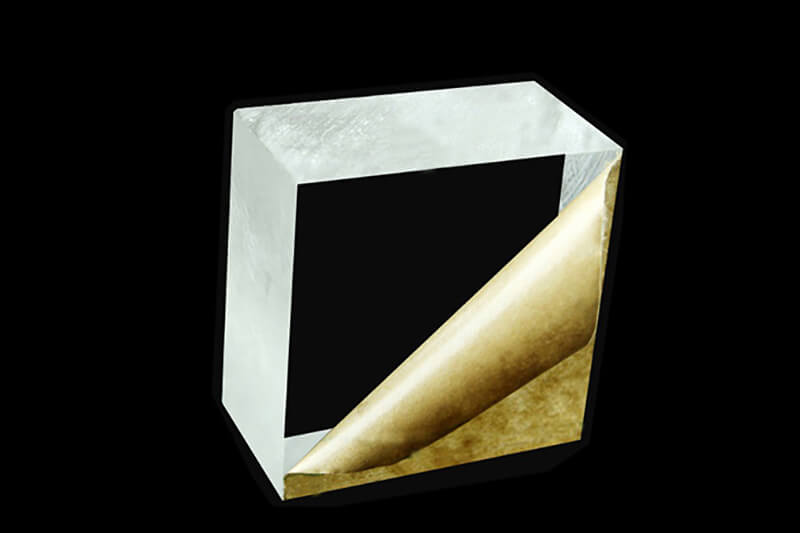

For manufacturing uses, acrylic is a great choice and a perfect fit for a lot of applications. They are easily machinable and can be thermoformed or molded into shapes easily.

Which makes them one of the most flexible and versatile plastics of all. We will learn more about the uses, applications, and advantages of using acrylic plastic below.

Common Characteristics of Acrylic Plastic

Acrylic or PMMA plastic has many characteristics and properties that make it popular in various industries. Let’s look at some of the most common properties that make it the first choice for most users.

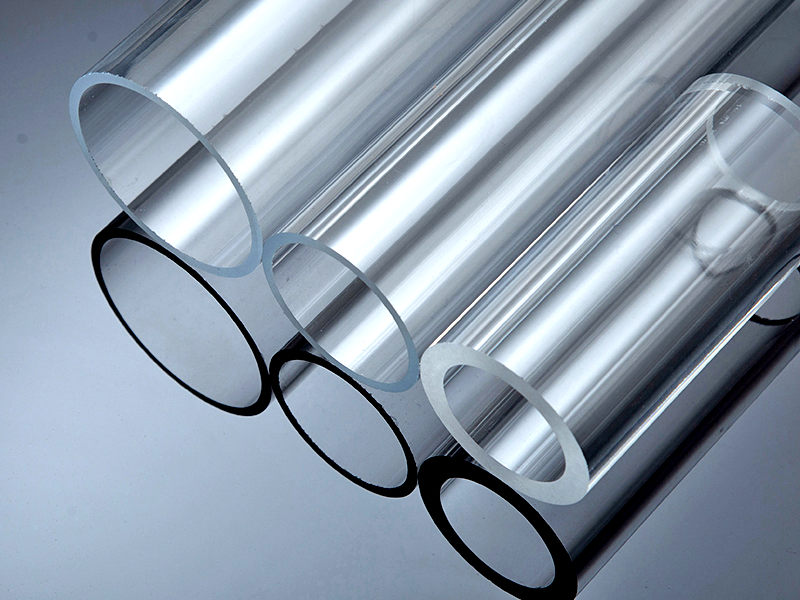

Common Applications of Acrylic Plastic

Acrylic plastics have a wide range of applications in various industries and uses. Starting from in-house personal projects to industrial or manufacturer needs, acrylic is a great option for all. Let’s explore some of the most well-known applications of acrylic plastic below.

Advantages of Using Acrylic Plastic

Disadvantages of Using Acrylic Plastic

Related Blogs

Looking for a trustworthy Supplier

Need a Trustworthy Supplier of Plastic, Foam, Sponge, Rubber, Metal, and Machining Solution. Click the Button, We Will Be In Touch With You As Quickly As Possible.