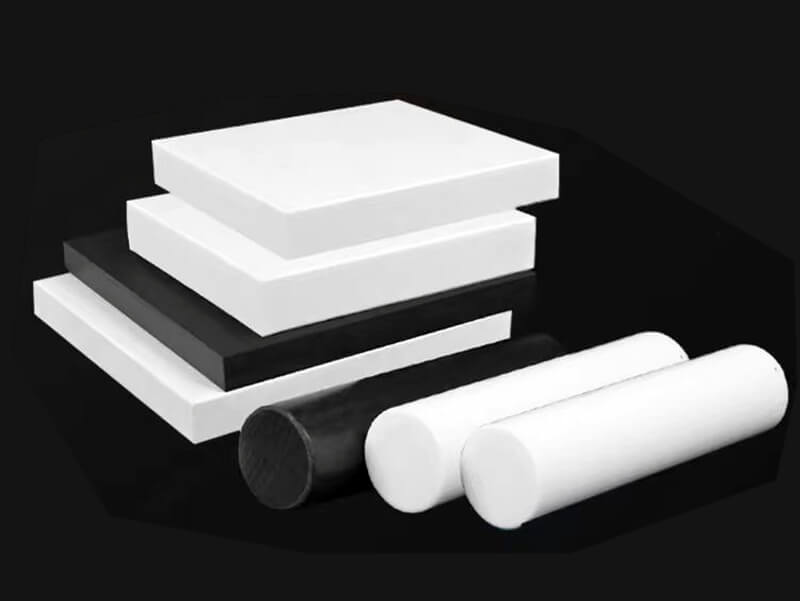

PTFE (Teflon) plastic in all forms

PTFE (Teflon) Sheet, PTFE (Teflon) Rod, Machining PTFE (Teflon) Parts…About PTFE (Teflon) plastic

PTFE is a semi-crystalline fluoropolymer widely used in many industries because it offers many excellent characteristics. Its chemical name is polytetrafluoroethylene, and DuPont discovered it in 1938. Therefore, PTFE is known as the brand name Teflon®.

PTFE (or Teflon) is an incredibly versatile material with many applications because it offers many excellent characteristics. For example, it provides extreme chemical resistance and thermal stability, making it suitable for seals and gaskets. PTFE also provides a very low coefficient of friction, excellent electrical resistance, and a non-stick surface. However, PTEF provides mechanical strength, but it can be improved by adding glass fiber, carbon, metal, mineral, etc.

PTFE (or Teflon) is usually formed into sheets, rods and tubes by compression and extrusion. It can also be made into some complicated parts/components by injection molding and CNC machining.

Specification about PTFE (Teflon) plastic

Grade

Profile/Shape

Production Process

Color

PTFE Sheet/Block

PTFE Rod

PTFE Tube

PTFE Film

Remark

Properties of PTFE/Teflon plastic

Main Usage of PTFE Plastic

Main Feature of PTFE Plastic

Industry

Can’t find what you need? Or have a technical question?

Leading Supplier of PTFE (Teflon) Plastic in China

UVTECO began to supply PTFE sheets/rods/films in 2003. In the meantime, we provide machining services according to client’s requirements. With more than 20 years of experience in PTFE, we know more about this material. We provide standard PTFE products and Modified PTFE plastics to meet different requirements from global clients.

For fast delivery to global clients, UVTECO stocks high-quality PTFE sheets, rods, tubes, and films in standard sizes. Meanwhile, UVTECO provides an integrated machining solution for PTFE-based parts/components. The main machining methods include cutting to size, drilling, 3-axis and 5-axis CNC milling, CNC Turning, injection molding, engraving, etc.

Today, UVTECO, an ISO-certified company, provides high-quality PTFE-base products/parts/components for over 2,500 clients in more than 45 countries.

Contact UVTECO for machining PTFE (Teflon) service

Related Blogs about PTFE (Teflon) Plastic

Frequently Asked Questions about PTFE

Looking for a trustworthy Supplier

Need a Trustworthy Supplier of Plastic, Foam, Sponge, Rubber, Metal, and Machining Solution. Click the Button, We Will Be In Touch With You As Quickly As Possible.