ABS Vs. PVC – A Comprehensive Guide

ABS or PVC? Explore the comparative strengths and weaknesses in our quick guide, helping you make an informed decision for your specific needs.

ABS and PVC are two pioneer plastic materials with nearly the same properties in terms of durability, stiffness, hardness, etc. These similar properties challenge professionals in their selection of the most effective and suitable construction material.

Moreover, in 2023, the market value of ABS and PVC plastics was $23 and $45 billion, respectively. These market propositions are growing with a CAGR above 4.9%.

All these demand that manufacturers, product designers, and engineers understand the context of ABS Vs. PVC. We evaluate these two materials by considering properties, applications, costs, etc. Let’s start

Understanding ABS Plastic

ABS plastic is also known as Acrylonitrile Butadiene Styrene as it contains monomers of acrylonitrile, butadiene, and styrene. It has been used for product production since the 1930s, with some degraded properties, such as brittle and low melting point.

As soon as the scientists improved this plastic’s capacity, it became a popular construction material and was patented in 1948. Finally, the Borg-Warner Corporation started its mass commercial use in 1954.

ABS plastic’s annual production is 14.22 million metric tons, expected to hit 19.52 metric tons within 2027.

How ABS Plastic Is Produced

In its production process, styrene and acrylonitrile undergo a polymerization process, forming shorter chains of polystyrene-co-acrylonitrile. After the addition of butadiene in the polymerization process, long chains of ABS are formed.

Finally, the solidification and termination of polymerization processes occur to develop industrial-use ABS plastic by adding influencing agents like colorants.

Pros and Cons of ABS Plastic Use

The following are the most competitive advantages and disadvantages of ABS plastic used in various end-items.

Pros

Cons

Understanding PVC Plastic

PVC, Polyvinyl Chloride, is the third-most produced plastic material. Each year, more than 40 million tons of PVC is produced globally. Historically, this plastic material was invented two times, in 1838 and 1872, by French physicist Henri Victor Regnault and German chemist Eugen Baumann, respectively. But both failed to understand its importance and so did the industries of that time.

Later, in 1913, the scientist Friedrich Heinrich August Klatte from Germany patented it. However, PVC’s commercial journey began in 1950 with improvements in its properties, production process, etc.

How PVC Plastic Is Produced

First, vinyl chloride is extracted from ethylene, hydrochloric acid, and oxygen chemical reactions in the presence of copper catalysts. The vinyl chloride monomers produced go through a polymerization process to form PVC chains.

Finally, depending on the desired quality, grade, and industrial requirements, additives are blended with the raw PVC produced. There are two types of PVC, including rigid and soft.

Pros and Cons of PVC Plastic Use

We list the most essential advantages and disadvantages associated with PVC use.

Pros

Cons

Side-by-Side Comparison of Properties of ABS and PVC

The table below showcases the differences between the physical, mechanical, and thermal properties of PVC and ABS plastics.

| Property Category | Properties | ABS | PVC |

|---|---|---|---|

| Physical Properties | Density | 1.3-1.58 g/cm³ | 1.38-1.45 g/cm³ |

| Chemical resistance | High | Moderate | |

| Moisture absorption | 0.05-1.80 % weight | 0.08-0.29 % weight | |

| Mechanical Properties | Tensile strength | 40-60 MPa | 45-60 MPa |

| Impact strength | 8-50 kJ/m² | 10-20 kJ/m² | |

| Hardness | Rockwell R 80 to R 114 | Rockwell R 80 to R 110 | |

| Thermal Properties | Thermal conductivity | 0.150 – 0.200 W/m-K | 0.120 – 0.190 W/m-K |

| Melting point | 230-260 °C | 80.0 – 196 °C |

Other Critical Aspects of PVC Vs. ABS

Here, we evaluate some critical aspects of both plastics, such as price, processing ease, environmental issues, etc.

Costs

According to Statista, in August 2023, the global price of PVC was $760 per metric ton, and it is still nearly the same. On the other hand, in the fourth quarter of 2023, the price of ABS plastic per metric ton was $1,280.

Recyclability

The PVC and ABS are recyclable. However, we observe that PVC is more recycled than ABS. This context vitally depends on the local recycling plant’s number and facilities.

Environmental Consideration

Apart from recyclability, other critical factors are associated with considering both plastics’ environmental impact. For instance, the PVC production process includes the generation of several harmful gases, which results in degraded human health and environmental pollution. On the contrary, the production of ABS does not generate such gases.

Processing Ease

ABS plastic is more easily processed than PVC. It is more suitable for injection molding and extrusion processes than PVC plastic.

ABS Vs. PVC Applications

| Industry | ABS | Rigid PVC |

|---|---|---|

| Plumbing | Drain, waste, and vent (DWV) systems | Water supply, drainage, sewerage systems |

| Automotive | Bumpers, trim panels, dashboard parts, interior trim | Floor modules, underbody coatings, and sealants |

| Packaging | Compact cases, caps, closures | Shrink wrap, cling film, and blister packaging |

| Consumer items | Toys, luggage, sporting equipment, furniture | Shoes, bank cards, bags |

| Household appliances | Vacuum cleaners, kitchen appliances, electronic enclosures | Light shades, wall and floor coverings, etc. |

Final Thoughts

This article covers every aspect of ABS Vs. PVC, which will help professionals select the best-suite material for product manufacturing.

Finally, ABS should be used in products that operate in low UV exposure, moderated temperature, etc., environments while incorporating impact resistance, sound dampening, etc. On the contrary, PVC plastic should be used outdoors while incorporating fire safety, easy installation, etc.

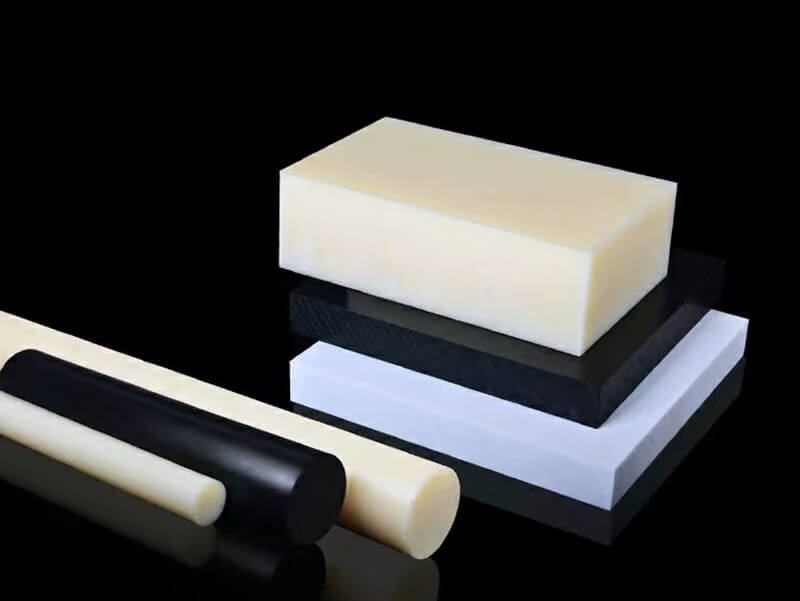

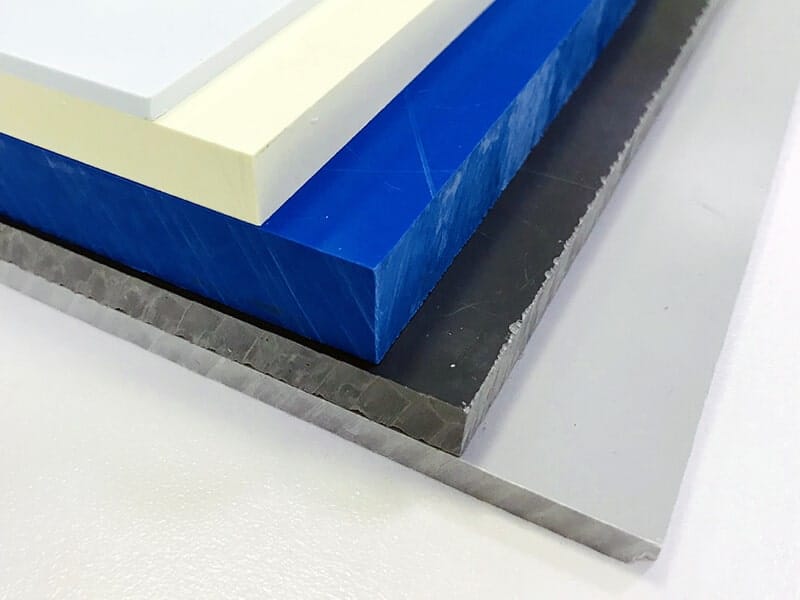

Reliable Supplier of ABS and PVC Plastic

UVTECO is an expert in engineering plastics, including ABS and PVC Plastic, in China. If you need ABS and PVC plastic sheets, rods, tubes, or machining services, please contact UVTECO and tell us your requirements.

Related Blogs

Looking for a trustworthy Supplier

Need a Trustworthy Supplier of Plastic, Foam, Sponge, Rubber, Metal, and Machining Solution. Click the Button, We Will Be In Touch With You As Quickly As Possible.