Polypropylene Vs Acrylic: Selecting the Perfect Material for Your Needs

Polypropylene is a thermoplastic polymer. It is often addressed by a short-form name –”PP.” This construction material is highly popular in various industries due to its strength, chemical resistance, recyclability, and cost-effectiveness. On the contrary, Acrylic is a thermoplastic homopolymer. It is also known asPolymethyl Methacrylate (PMMA). Weather resistiveness and durability are the two prime properties of this material.

Both of the materials have their unique properties, applications, advantages, and disadvantages. A sound understanding of the differences in terms of Polypropylene vs Acrylic can assist the experts in selecting the right construction material for the product construction. Here, we detail this so you can select the perfect material for your needs.

Polypropylene: Everything You Need to Know

Polypropylene was invented by two Italian chemists, Giulio Natta and Karl Ziegler, in 1954. They independently discovered the polymerization process for propylene by employing catalysts. Here, the catalysts were invented by Karl Ziegler. For these remarkable inventions, Natta and Ziegler both received the Nobel Prize in 1963.

The production process of Polypropylene is a critical chemical process known as polymerization. In this process, propylene gas undergoes a transformation in the presence of a Ziegler-Natta or metallocene catalyst. Here, factors like temperature, pressure, etc., are carefully controlled as per the desired grade of Polypropylene output.

Common Characteristics of Polypropylene

The following are the core characteristics of Polypropylene.

Common Applications of Polypropylene

Below are the highlighted applications of Polypropylene.

Advantages of Polypropylene

Here, we list some advantages of using Polypropylene as a construction material.

- Polypropylene does not accommodate any static electricity.

- It is highly cost-effective.

- It is considered a non-toxic solution to produce high-quality final products.

- Polypropylene is considered food safe.

- It can be bent easily. In recovery, it retains its original shape without breaking.

Disadvantages of Polypropylene

Below are the associated disadvantages of Polypropylene.

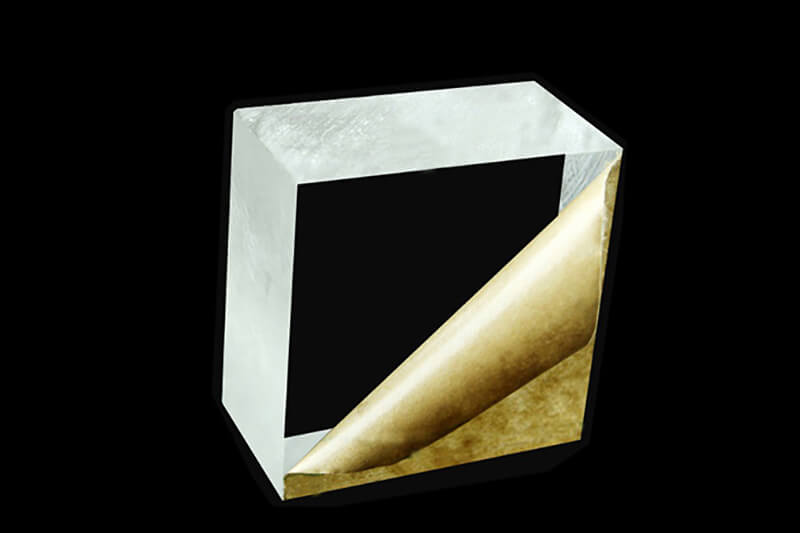

Acrylic: Everything You Need to Know

Acrylic was invented by the German chemist Otto Röhm. In 1901, Röhm discovered the process for methyl methacrylate polymerization forming PMMA. But, its commercial journey started later in 1933 under the trademark “Plexiglas.”

The process of forming Acrylic is known as Bulk polymerization. In this process, this material is made by mixing methyl methacrylate with a special substance called a catalyst. The mixing happens in a mold. Following this, a chemical reaction takes place in the mold under sealed and heated conditions.

Common Characteristics of Acrylic

Below are the must-know properties of Acrylic.

Common Applications of Acrylic

Here is the use of Acrylic.

Advantages of Acrylic

Here are the advantages of using Acrylic.

Disadvantages of Acrylic

Below is a list of issues associated with Acrylic use.

Comparison Between Polypropylene Vs Acrylic

| Type | Polypropylene | Acrylic |

|---|---|---|

| Short description | Polypropylene is a thermoplastic polymer | Acrylic is a thermoplastic homopolymer |

| What ingredients used to make this | Propylene gas, Ziegler-Natta or metallocene catalyst | Methyl methacrylate, catalyst |

| Applications | Polypropylene is used to manufacture car parts, geotextiles, outdoor furniture, pipes, storage boxes, etc. | skylights, domes, canopies, lenses, LCD displays, paints, etc. |

| Characteristics | It can deal with extreme temperatures. Semi-rigid. Low-density. Recyclable. | Impact, weather, and UV resistance. Lightweight. Easy to process. |

| Trade Name | Proteus, Propylux, etc. | Crylux, Hesalite, Plexiglas, etc. |

| Price | Per Ton Polypropylene price ranges from $1,700 to $2,000 | Per Ton price is $2,000 to $2,500. |

Final words

Polypropylene and acrylic are the popular engineering plastic, they offer different performance and suitable for different applications. If you don’t know how to choose them for your project and looking for a trustworthy supplier, contact us now!

Related Blogs

Looking for a trustworthy Supplier

Need a Trustworthy Supplier of Plastic, Foam, Sponge, Rubber, Metal, and Machining Solution. Click the Button, We Will Be In Touch With You As Quickly As Possible.