Anti Static polycarbonate Sheet

Electrostatic Dissipative Polycarbonate with 106 or 108 Ohm Surface ResistanceAbout Anti-static Polycarbonate

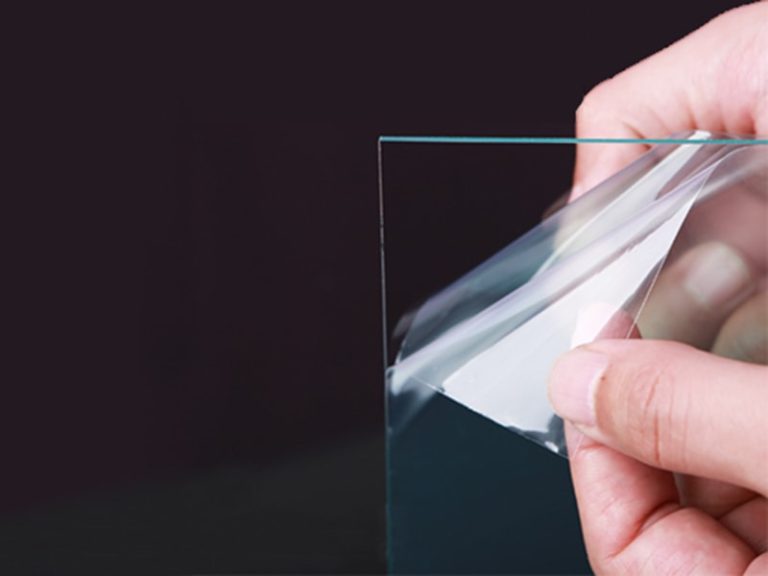

Anti-static polycarbonate is designed to prevent and control the generation of static electricity on the surface. It is produced by coating an electrostatic dissipative layer on the surface of a plastic sheet. Therefore, the surface resistance stabilizes from 106 to 108 Ohm. Antistatic polycarbonate is also known as “ESD Polycarbonate” or “Electrostatic Dissipative Polycarbonate.”

This electrostatic dissipative layer is usually coated on a transparent plastic sheet. It won’t change the original plastic sheet’s physical properties or light transmittance. Common materials include polycarbonate, acrylic, Rigid PVC, etc.

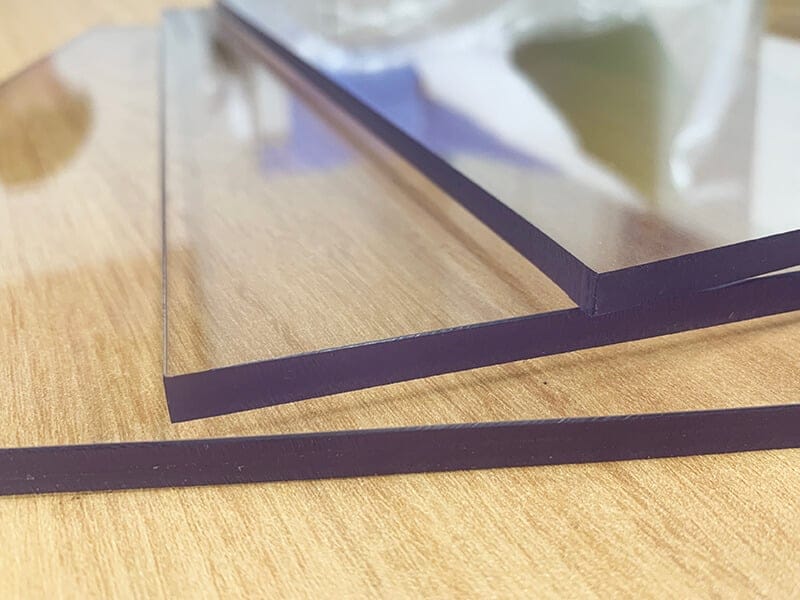

Compared with the original polycarbonate sheets, Anti-static Polycarbonate offers the same impact resistance, light transmittance, and flame resistance but better surface hardness and wear resistance. It is used in semiconductors, electronic equipment’s safety cover, and machines’ enclosures in specific environments.

Specification of Anti-static Polycarbonate

Anti Static polycarbonate

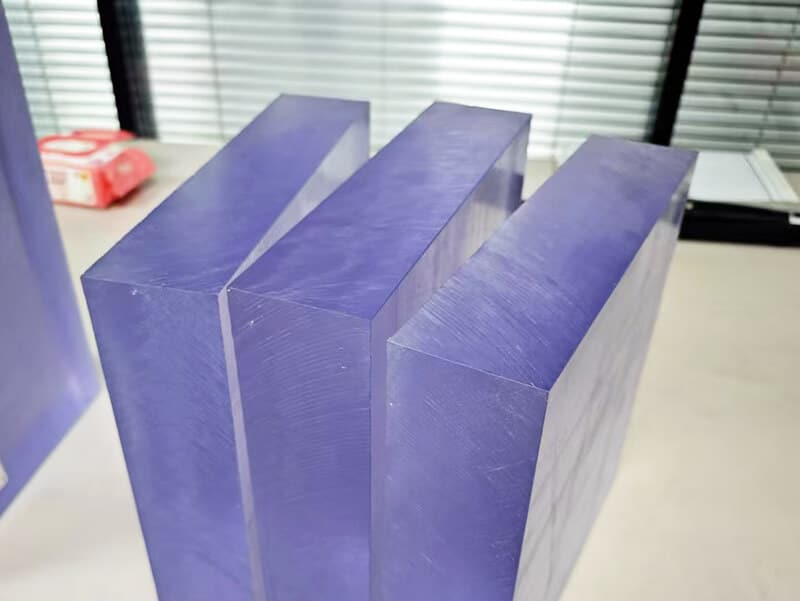

UVTECO stocks polycarbonate films in different grades, surfaces, and thicknesses. Otherwise, we can provide the part by machining polycarbonate film by UV printing, silk-screen printing, routing, cutting, die-cutting, vacuum molding, etc.

Product Range

| Grade | Model | Thickness | Width | Length |

|---|---|---|---|---|

| General Purpose | UTPC-ESD-GP | 1mm to 15mm | 1180mm, 1220mm | 2440mm |

| Durable | UTPC-ESD-D | 1mm to 15mm | 1180mm, 1220mm | 2440mm |

| Bendable | UTPC-ESD-B | 1mm to 15mm | 1180mm, 1220mm | 2440mm |

Properties of anti static Polycarbonate

Main Usage of Anti Static Polycarbonate

Main Feature of Anti Static Polycarbonate

Can’t find what you need? Or need a Support From Engineer?

Leading Supplier of Anti-Static Polycarbonate in China

UVTECO is a leading supplier of anti-static polycarbonate in China and provides it to global clients. By using high-quality polycarbonate plastic and advanced coating technology, we can manufacture high-quality anti-static polycarbonate sheets with different grades, satisfying most clients from different industries. Otherwise, UVTECO can machine the Anti-static polycarbonate Sheets according to requirements from global clients by various processes, including cutting, bending, drilling, CNC milling, etc.

UVTECO is one of the wholly owned subsidiaries of UVPLASTIC, which has been active in the engineering plastic field since 1995 and began manufacturing polycarbonate sheets in 2003. Today, UVTECO provides high-quality polycarbonate sheets, parts, and components for over 2,500 clients from more than 45 countries. They work in the automobile industry, semiconductors, microelectronics, machine vision, inspection equipment, medical devices, food machinery, metaverse, aerospace industry, safety equipment, security glass, agriculture, architecture, etc.

Contact UVTECO for machining Anti Static Polycarbonate service

Related Products about Anti-Static Polycarbonate

Related Blogs about Anti-Static Polycarbonate

Frequently Asked Questions about Anti-Static Polycarbonate

Looking for a trustworthy Supplier

Need a Trustworthy Supplier of Plastic, Foam, Sponge, Rubber, Metal, and Machining Solution. Click the Button, We Will Be In Touch With You As Quickly As Possible.