HDPE Vs. PVC Sheets: Choosing the Best Material for Your Project

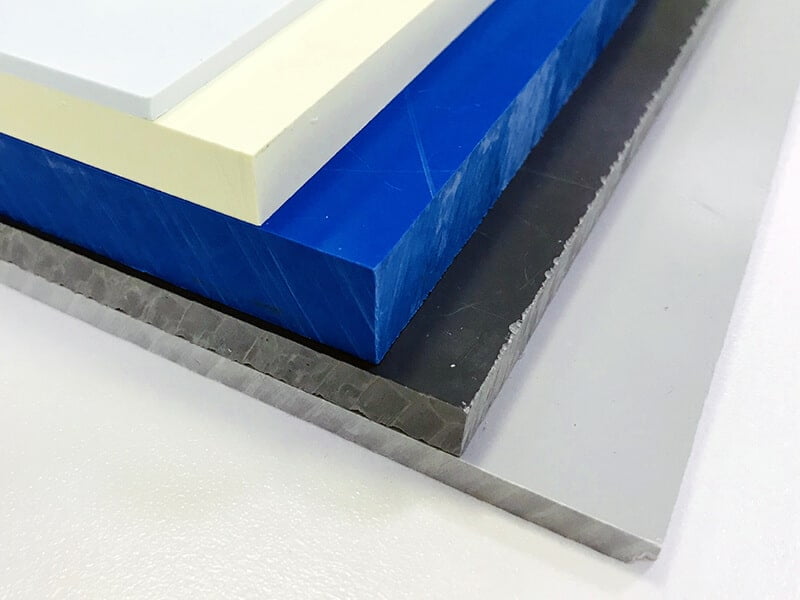

HDPE is a popular thermoplastic polymer because it offers superior properties in terms of versatility, strength, and durability. This construction material’s full form is high-density Polyethylene and has a high strength-to-density ratio. On the other hand, PVC is a polymer, and its full form is Polyvinyl Chloride sheets. This material is equipped with excellent properties, durability, resistivity, and flexibility.

Understanding various aspects of HDPE and PVC sheets allows professionals to make well-informed decisions in the construction material selection process. Knowing these construction materials’ properties, applications, pros, and cons assists you in choosing the best material for your project. Here, we detail the relevant aspects while differentiating the materials.

HDPE: Everything you need to know

HDPE was developed by Nobel Prize winner Karl Ziegler in 1953. To produce commercial-use HDPE, Karl used the concept of the polymerization process of producing polypropylene which was invented by Paul Hogan and Robert Banks in 195.

Today, in general, HDPE is produced by using a technique named slurry polymerization. This process starts with the application of intense heat to petroleum. Here, ethylene gas is formed. Following this, a catalyst and a small quantity of liquid ethylene are placed in a reactor to form a slurry. To finalize the polymerization, the previously produced ethylene gas is inserted into the reactor, which causes monomers to polymerize. Finally, the HDPE is extracted.

Common Characteristics of HDPE Plastic

Common Applications of HDPE

Below are the most common uses of this material.

Advantages of HDPE Plastic

Here, we detail the advantages of using HDPE.

Disadvantages of HDPE

Below are the disadvantages of HDPE.

PVC Sheets: Everything You Need to Know

PVC was accidentally invented by German chemist Eugen Baumann when he tried to polymerize vinyl chloride gas in 1872. However, he failed to recognize the importance of this material. Later, in 1912, Fritz Klatte, a German chemist, introduced the process of forming PVC commercially. However, to make PVC sheets popular, Waldo Semon, a chemist in USA-based B.F. Goodrich Company, is considered a pioneer.

The first step in producing a PVC sheet is to form ethylene dichloride by combining chlorine and ethylene. Then, under high temperatures, this mixture forms vinyl chloride monomers, which are the base of PVC. After appropriate polymerization of vinyl chloride monomer, the final PVC is formed. Finally, PVC is produced in various sheet sizes to supply ready-to-use PVC sheets in the market.

PVC plastic includes rigid and soft PVC plastic, but we only provide rigid PVC plastic, including sheets and rods.

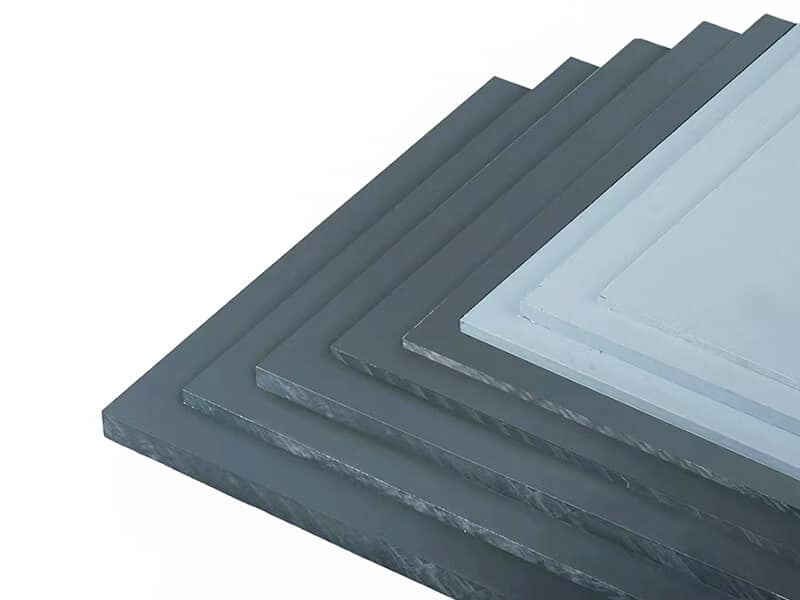

Common Characteristics of PVC Sheets

The following are the base characteristics of PVC sheets.

Common Applications of PVC Plastic

Here, we list some common applications of PVC sheets.

Advantages of PVC Plastic

Here are some must-know advantages of this material.

Disadvantages of PVC Plastic

Two issues we would like to mention here about this material.

Comparison Between Product HDPE Vs. PVC Sheet

| Type | HDPE Sheet | PVC Sheets |

|---|---|---|

| Short description | HDPE is high-density Polyethylene | PVC is a polymer |

| What ingredients used to make this | Liquid and gas ethylene from petroleum, catalysts | Chlorine and ethylene |

| Applications | HDPE is used to manufacture pipes, bottles, lids, auto parts, trash bins, etc. | PVC sheets are used to make vehicles’ roofs, decorating items, furniture, display boards, etc. |

| Characteristics | It provides a higher degree of strength, stiffness, and durability. It has a low moisture absorption rate. It is also recyclable. | Non-flammable, weather-resistant, high tensile strength. |

| Trade Name | HiTec, Paxon, King Colorboard, etc. | Anwidur, Apex, etc. |

| Price | Per Ton HDPE price ranges from $1,143 to $1,250 | The per-square-foot price is $0.30 to $1.34. It depends on quality, color, thickness, etc. |

Final Words

Although some plastic parts/components can be made from HDPE and PVC plastic, they are different engineering plastics. If you don’t know how to choose for your project, please contact UVTECO. UVTECO is a trustworthy supplier of HDPE and PVC plastic from China, and we can help you.

Related Blogs

Looking for a trustworthy Supplier

Need a Trustworthy Supplier of Plastic, Foam, Sponge, Rubber, Metal, and Machining Solution. Click the Button, We Will Be In Touch With You As Quickly As Possible.