A Guide for Machining Delrin

Effortless precision awaits! Explore the fundamentals of machining in Delrin with our concise guide. Master the basics and essential techniques.

The Delrin POM has some important and separate features from other thermoplastics. It comes in different colors and properties. On the other hand, Delrin ensured dimensional stability for manufacturing complex parts with precise dimensions. It also ensures super tensile strength to obtain stiff and wear-resistant consumer products.

Those essential features make this thermoplastic the alternative to metal in many cases. Here in this article we will try to figure out how this thermoplastic takes care of durable and tough part manufacturing with precise machining.

What is Delrin?

Derlin is a semicrystalline-engineered thermoplastic. It is also known as acetal homopolymer or Polyoxymethylene (POM). This engineered plastic ensures durability, tensile strength, good structural integrity and wear resistance with efficient low friction ability.

The melting point of Delrin is 175°C with 1.410–1.420 g/cm3 density. It is available in many colors and addled in its natural state. However, the crystallinity of this stiff plastic is 70-75%. These technical properties make Delrin the best alternative of metal to produce high tensile strength mechanical parts. Lots of manufacturers are replacing metallic safety restraints, door systems, conveyor belts, and gears with Polyoxymethylene (POM) or Delrin.

Popular Delrin Machining

This Polyoxymethylene (POM) plastic is only shot to replace metal for its precise machining features. Here we will explore the popular machining process to manufacture proper dimensional consumer products and parts.

3D Printing

3D printing is a popular part machining technology. Along with other plastic materials Delrin is also suitable for performing 3D printing product manufacturing. However, there are two POM filaments Gizmo Dorks Acetal and HobbyKing that are mostly used in 3D printing. Though this process has some challenges during machining, it can be efficient in some manufacturing projects.

Injection Molding

Injection molding is one of the most popular machining processes for plastic materials. As we know the Delrin is a highly productive plastic so it can be used in the injection molding process.

However, this machining process ensured high-quality surface finishing and super pressure tolerance capable of part manufacturing. Besides other facilities and limitations, POM plastic or Delrin are a suitable material for injection molding methods.

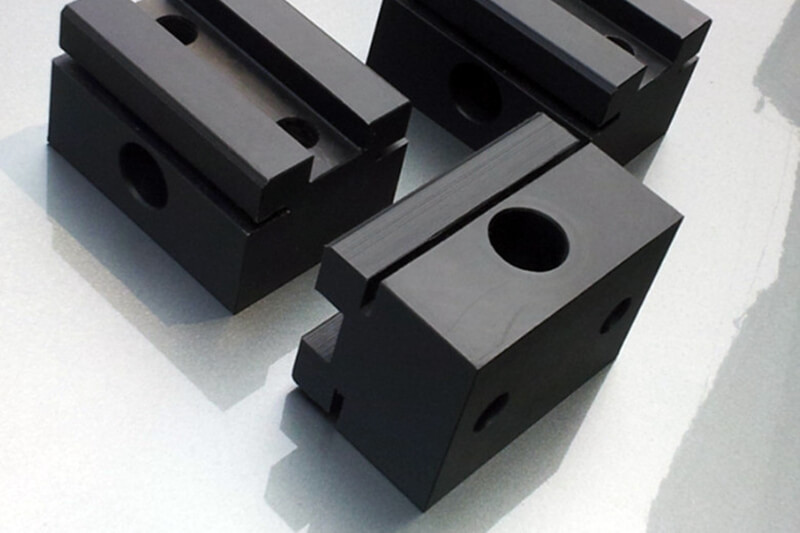

Delrin CNC Machining

As we already know, CNC is the most popular and advanced machining process for producing high quality and quality full surface finished consumer products. On the other hand, the Derlin thermoplastic ensures better dimensional stability.

Together the thermoplastic and the CNC machine can produce products and perts with the minimum tight tolerance of +/-0.005. Overall, POM CNC operations ensure the proper matching of the Delrin thermoplastic.

Surface Finishing of Machined Delrin

Proper surface finishing is an essential process after machining a part or product. In that case, there are two processes of the Delrin thermoplastic surface finishing.

Machined Finish

The machined finish is also known as “as-machined” finish. That means in this process the part finished will remain in the same state after finishing manufacturing. In other words, there will be no after-machining surface finishing process to soften the machining texture or rough surface. So, this process is suitable for manufacturing parts that require proper grip.

Bead Blast Finish

This machining process is applied when the thermoplastic needs a smooth surface and polished look. In addition, bead blast finishing is performed to finish the surface to reduce friction and improve the durability of that certain product or part. However, this process maintains a good surface finish to hide any manufacturing defects with precise finishing.

Real-Life Delrin Machining Tips

Here are some important tips during Delrin thermoplastic machining.

Ensure Wall Thickness

Maintaining the wall thickness is important for part design in Delrin thermoplastic. The thickness also ensures easy large-part wrapping.

Control Temperature

POM thermoplastic is sensitive to high temperatures above 121°C. So, you have to apply cooling methods properly. For instance, air-based coolant works better in POM than liquid coolants.

Use Clean Tool

While applying coolants to the machining, it is also essential to remove the material chips properly. Otherwise, the machining might reduce the surface finishing by damaging the part.

Avoid Contamination

Ensure you are not using the same cutting tool that you used in the aluminum and other materials machining.

Light Clamping

The Delrin thermoplastic is not suitable for tight clamping during machining. To avoid inconvenience while machining, ensure the workpiece is clamped lightly.

Sharp Cutting Tool

The cutting tool is the main part of CNC machining. Hence using a sharp cutting tool will increase part manufacturing without any design flow.

Advantage Of CNC Machining Delrin

Delrin or Polyoxymethylene (POM) thermoplastic comes with different types of advantages. Here are the advantages of the Delrin machinings.

Dimensional Stability

How well a workpiece can manage stress during machining ensures dimensional stability. In that case, the POM thermoplastic has exceptional dimensional stability as it remains in the same state while machining. In other words, Delrin does not change the shape and size of its stationary position during CNC machining.

Better Machinability

Machinability advancement of the POM thermoplastic is at the upper level. This plastic is a free-cut material that provides top-notch machinability to manufacture complex geometrical parts.

Lightweight

Delrin is a lightweight thermoplastic regarding other metals. However, this material might be lightweight but provides high tensile strength as other metals. So, this plastic can work as a high-stress material like several metals.

Moisture Absorption

Apart from other engineered thermoplastics, Delrin provides a low moisture absorption facility. That means, it will withstand any moisture conditions like tight water seals or manufacture marine products.

Popular Delrin Applications

Here are some popular Delrin applications that are replacing metals.

Medical

Manufacturing medical instruments like inhalers, insulin pens, surgical staplers, etc are made with POM thermoplastic.

Automotive

In the automotive part manufacturing the Delrin thermoplastic is used to produce fuel sender units, articulated shells, door lock systems, hinged housing, etc.

Furniture

Plastic has become one of the finest materials for durable plastic furniture. So, the POM thermoplastic material is used to produce furniture parts like handles, locks, hinges, and other related hardware.

Industrial

Delrin has plenty of industrial advancement for producing parts like scraper blades, valves, bearings, rollers, gears, housings, springs, fan wheels, etc.

Electrical

Consumer electrical part manufacturing is also one of the popular applications of the Delrin thermoplastic. It helps to manufacture insulators, connectors, bobbins, and other electrical parts.

Top Supplier of Delrin Plastic parts

UVTECO is a leading supplier of Delrin Parts in China. Normally, we stock Delrin Plastic in Sheet/Rod/Tube with common sizes and colors for fast delivery to global clients. Meantime, we provide machining services. Contact us now if you are looking for a trustworthy supplier of Delrin parts/components.

Final Word

The acetal homopolymer or Polyoxymethylene (POM) thermoplastic has similar features according to other metals. This material provides necessary part manufacturing advancements with similar metal properties. That is why the Delrin part manufacturing process established a good impression in the industrial world.

Related Blogs

Looking for a trustworthy Supplier

Need a Trustworthy Supplier of Plastic, Foam, Sponge, Rubber, Metal, and Machining Solution. Click the Button, We Will Be In Touch With You As Quickly As Possible.