HDPE Vs. Polycarbonate: A Comparative Analysis for Material Selection

High-density polyethylene (HDPE) is a flexible polymer that has existed for a long time. It is made from hydrocarbons. HDPE has fewer side branches than other polyethylene (PE) types, making it denser. HDPE is often used to package chemicals like bleach and soap for use in the home.

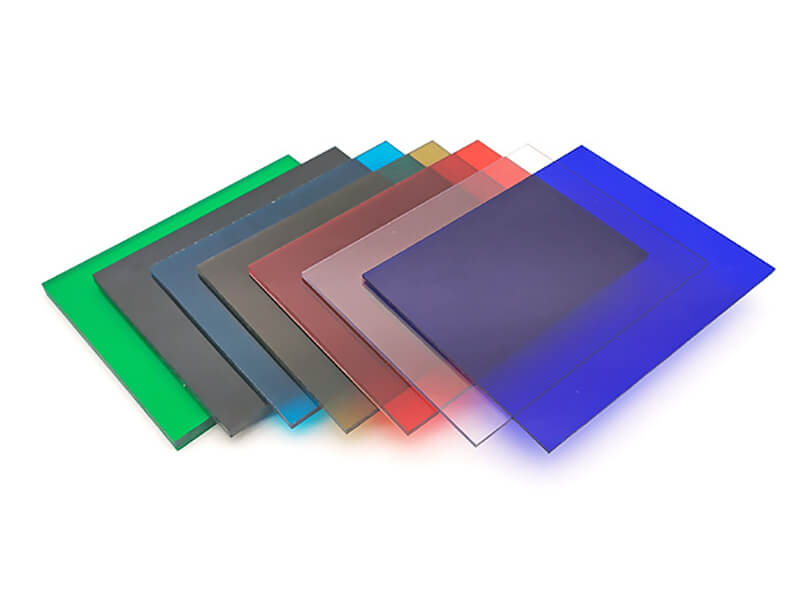

Polycarbonate plastic (PC) is a solid and durable material that lets light through very well. It allows more light through than glass because it is flexible, has a high refractive index, and absorbs light in the UV range. It is a suitable replacement for glass in many situations because it has these qualities and is hard to break.

This article will compare HDPE and polycarbonate in terms of applications, characteristics, advantages, and disadvantages.

HDPE Plastic: Everything you need to know

High-Density Polyethylene (HDPE) is a group of medium to high-density polyethylenes. They are all the same chemically, and the only things that make them different are the side-branched monomers’ number, regularity, and size. In a high-pressure reaction chamber, the byproducts of diazomethane are used to make repeated chains of CH2.

By controlling the polymerization process, HDPE becomes more substantial, stiffer, and challenging. It is often used to make filament for 3D printers, car fuel tanks, packing materials, and boat parts.

Common Characteristics of HDPE Plastic

Before understanding how it is used in business, you must know what it is. So, here are some Characteristics of HDPE Plastic:

Some grades are made to meet your unique needs, such as being resistant to environmental stress cracking (ESCR), stiff, not shrinking much, UV-stabilized, etc.

Common Applications of HDPE Plastic

Advantages of HDPE Plastic

HDPE plastic is famous for its advantages over other materials that make it stand out. Here is a short list of the benefits of HDPE:

Disadvantages of HDPE Plastic

HDPE has some disadvantages, just like every other material. Here is a short list of the disadvantages of HDPE plastic:

Polycarbonate Plastic: Everything you need to know

Polycarbonate (PC) is the best material for uses that must be clear and strong enough to withstand a hit. Even though it scratches easily, the use of various hard coats compensates for this. This could make the surface one of the most scratch-resistant of all plastics. Because it has a refractive value of 1.58, it is an excellent choice for optics and corrective lenses.

Even though the material doesn’t hold up well to UV light, using hard coats and adding antioxidants during molding make up for this.

Common Characteristics of Polycarbonate Plastic

Here are some common vital Characteristics and specifications to give you an idea of what to expect:

Common Applications of Polycarbonate Plastic

Advantages of Polycarbonate Plastic

Some advantages of Polycarbonate:

Disadvantages of Polycarbonate Plastic

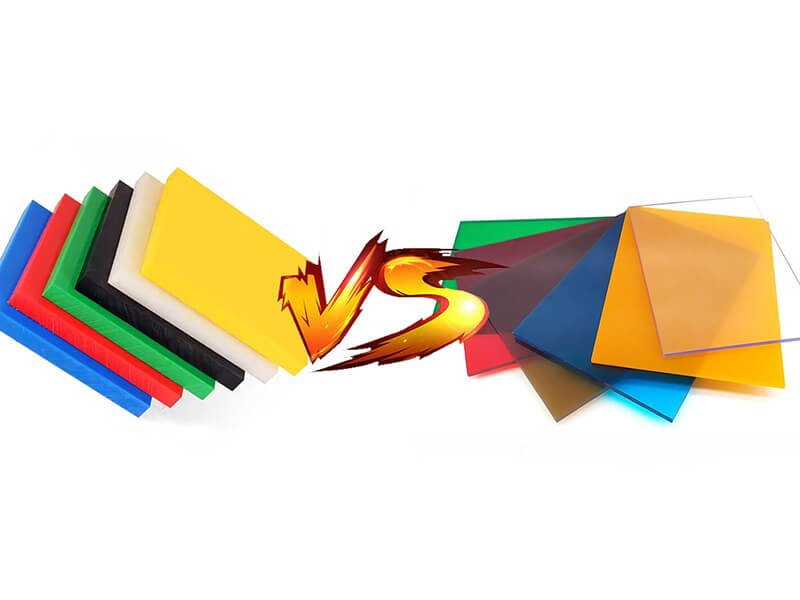

Comparison Between HDPE Vs. Polycarbonate Plastic

| Type | HDPE Plastic | Polycarbonate Plastic |

|---|---|---|

| Short description | High-Density Polyethylene (HDPE) is a petroleum-based thermoplastic material. | Polycarbonate is a strong, clear plastic that is very stiff and can take a lot of force without breaking. |

| What ingredients used to make this | High-density polyethylene (HDPE) is the linear form of polyethylene, a light, flexible resin that combines ethylene molecules. | Most of the time, Polycarbonate is made when bisphenol A and carbonyl chloride combine at the surface of a liquid. |

| applications | HDPE was used to make many things, like containers for food and drinks, boxes for cleaning products, pipes, cutting boards, and some shoe parts. | Some of the most popular uses are compact discs, safety helmets, bullet-proof glass, car headlamp lenses, baby feeding bottles, roofing, glazing, etc. |

| characteristics | Flexible, precise, or waxy, waterproof, strong at low temperatures (down to -60°C), easy to work with in most ways, cheap, and resistant to chemicals. | Polycarbonates are engineering thermoplastics that are strong, stiff, complex, rigid, and transparent and can stay stiff up to 140°C and tough down to -20°C or even lower in some grades. |

| Pros | HDPE is more rigid and lasts longer. It comes in different shades, from clear to dark, and is chemical resistant. | Fireproof, vandal-proof, durable, protective, and light. Simple to use in a machine. |

| Cons | HDPE is flammable, breaks easily under stress, and can’t be broken down by nature. | The main problem with plastic is that it’s easy to scratch. |

Final Words

HDPE plastic is different from polycarbonate plastic, but some plastic parts/components can be made from either. If you don’t know which to choose for your project, please contact UVTECO. UVTECO, as an expert in material and machining solutions, will be a trustworthy supplier of HDPE and polycarbonate plastic from China, and we can help you with that.

Related Blogs

Looking for a trustworthy Supplier

Need a Trustworthy Supplier of Plastic, Foam, Sponge, Rubber, Metal, and Machining Solution. Click the Button, We Will Be In Touch With You As Quickly As Possible.