ABS Vs. Polyethylene Plastic – Exploring the Pros and Cons

ABS and Polyethylene plastics have carved niches in various industries due to their unique properties and versatility. Their adaptability allows them to excel in various manufacturing applications, from industrial uses to everyday household items.

This article will dive into the details of both plastics, clearing the path for a confident decision-making process. Whether you’re working on an industrial, or personal project, choosing the perfect plastic will no longer be a puzzle.

Let’s explore the pros and cons of ABS and polyethylene plastics, and set you on the path to plastic prowess.

ABS Plastic: Everything you need to know

ABS stands for Acrylonitrile Butadiene Styrene. It’s like a triple threat in the plastic world, made from three incredible ingredients: acrylonitrile, butadiene, and styrene. It is known for its versatility and wide range of applications.

ABS is a thermoplastic polymer possessing remarkable characteristics. It can be molded and shaped at high temperatures and solidified at cooler temperatures without significant degradation from thermal cycling. This unique quality allows ABS to be formed into various shapes, making it an excellent choice for various applications, products, and prototyping needs.

Common Characteristics of ABS Plastic

Some common characteristics of standard ABS plastic are given below:

Common Applications of ABS Plastic

ABS materials are extensively used in various industries. Here are some common applications of it:

Advantages of Using ABS Plastic

Disadvantages of using ABS Plastic

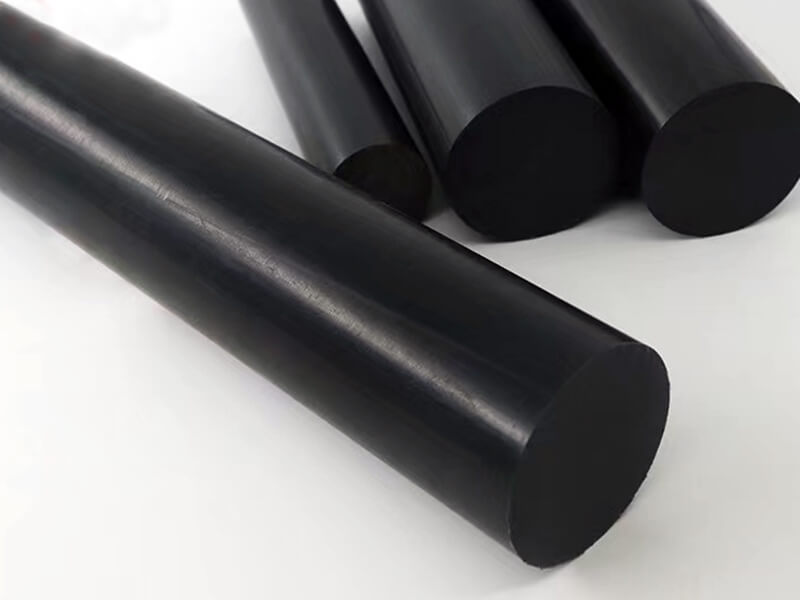

Polyethylene Plastic: Everything you need to know

Polyethylene plastic is a thermoplastic polymer with a wide range of applications across various industries. It is one of the most produced plastics in the world. From packaging and household items to industrial components and medical devices, polyethylene is practically everywhere these days.

Polyethylene Plastic is lightweight and durable. It is made from the polymerization of ethylene (or ethene) monomer, which contributes to its flexibility and resilience. In this part of the article, you will learn more about Polyethylene plastic, its usage, applications, and advantages.

Common Characteristics of Polyethylene Plastic

Common characteristics of polyethylene plastic include:

Common Applications of Polyethylene Plastic

Polyethylene plastic finds typical applications in various industries as following:

Advantages of Using Polyethylene Plastic

Disadvantages of Using Polyethylene Plastic

Comparison Between ABS and Polyethylene

| ABS | Polyethylene |

|---|---|

| Strong and durable plastic used in diverse industries. | A versatile thermoplastic used in various industries. |

| ABS is made of acrylonitrile, butadiene, and styrene. | Polyethylene is made from polymerization of ethylene monomers. |

| Used in automotive parts, Consumer products, Pipes and fittings, Protective equipment, Musical instruments | Used in Packaging materials, Pipes and fittings, Electrical insulation, Medical equipment, Agricultural films |

| Exceptional strength and long-lasting performance. | Highly Flexible |

| ABS tends to produce longer, stringy chips during machining. | Polyethylene produces shorter, more granular chips. |

| ABS is more expensive compared to polyethylene | Polyethylene is generally more cost-effective. |

Final Words

ABS and Polyethylene are similar plastics, but their prices are different. If both materials suit your parts/components, you can choose a cheaper one. If you don’t know how to choose, contact UVETCO, an expert in material and machining solutions.

Related Blogs

Looking for a trustworthy Supplier

Need a Trustworthy Supplier of Plastic, Foam, Sponge, Rubber, Metal, and Machining Solution. Click the Button, We Will Be In Touch With You As Quickly As Possible.