G10 Epoxy Sheet: Features and Applications Explained

Understand what is a G10 epoxy sheet to ensure effective use of the materials. Also, knowing its features assists professions in the right material selection.

G10, also called “Garolite Grade 10” is a high-performance composite material. With exceptional mechanical strength, electrical insulation, resistance to moisture and chemicals, etc. G10 is widely desired in many prominent industries including aerospace, automotive, electronics, and so on.

Following these, industry professionals, designers, and manufacturers must know what a G10 epoxy sheet is for effective use. Moreover, understanding G10 features assists stakeholders in the correct material selection, cost control, application suitability identification, and many more. Here, we are about to cover all these aspects in detail.

Basics of G10 Fiberglass Epoxy Laminate Sheet

This section elaborates on the basics of the G10 epoxy sheet by discussing its production process, advantages associated with use, appearance, and most common applications.

Production Process of G10 Epoxy Sheet

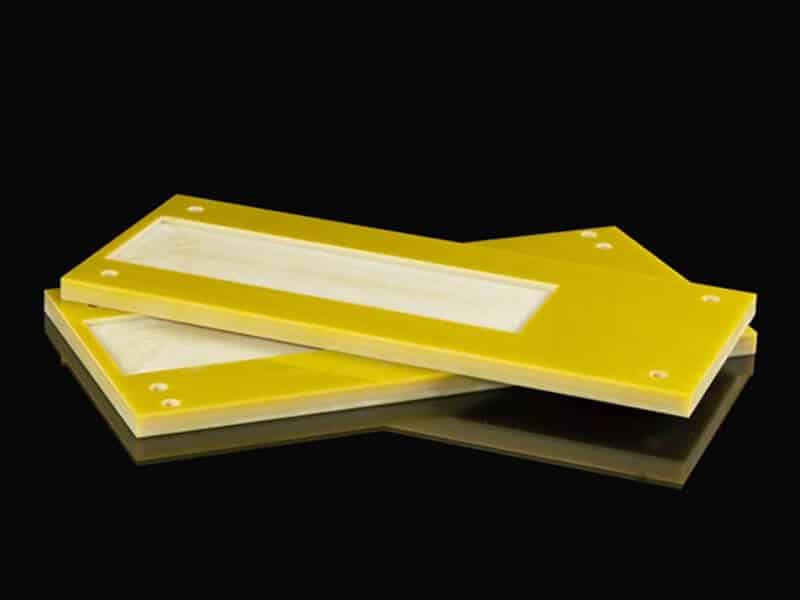

Appearance of G10 Epoxy Sheet

In general, G10 epoxy sheets are naturally greenish and black. However, as per the order’s requirements, the manufacturers can produce G10 sheets in a wide variety of colors. The surface finish of G10 sheets is smooth and glossy. Again, many manufacturers add additional coatings or polishings to enhance the aesthetics of the sheets.

Most Common Applications of G10 Sheets

Key Features of G10 Epoxy Sheets

The following are the details.

Superior Mechanical Strength

The tensile and compressive strengths of G10 sheets are 40,000 PSI and 65,000 PSI. These higher levels of mechanical strength make G10 critically suitable for structural and load-bearing applications.

Excellent Electrical Insulation

With 550 Volts/mil dielectric strengths and a non-conductive nature, G10 is considered superior for electrical insulation. Due to its composite formation, this material does not conduct electricity readily.

Promising Thermal Properties

As per ASTM C177, G10’s thermal conductivity is 0.288 W/m-k, and the maximum service temperature is 140 °C. However, by imposing extended efforts and specialized procedures, G10’s service temperature can touch 330 °C.

Most importantly, its thermal property of withstanding subzero temperature makes it suitable for cryogenic applications.

Exceptional Chemical Resistance

G10 epoxy sheets showcase remarkable chemical resistance properties. It is resistant to strong acids and alkalis. Also, G10 can resist the contaminations triggered by many solvents, bases, and hydrocarbons.

Remarkably Lightweight

The G10 sheets’ associated strength-to-weight ratio is considered superb. This lightweight nature makes G10 an easy-to-handle and easy-to-install material. The associated lightweightness also allows professionals to use it in the production of a diverse range of items.

Cost-effective Machining

The inherited compositeness of G10 allows easy cutting, drilling, and shaping of the G10 sheet. In this case, industry professionals can give it a customized form without affecting its integrity.

Most importantly, G10’s CNC machining is highly cost-effective due to low resource requirements.

Competitive Advantages of Using G10

The following are the competitive advantages of using G10 in parts and parts components manufacturing.

Expert Tips on Using G10 Epoxy Sheets in Applications

The following tips are provided by our experienced and skilled experts.

Final Words

G10 epoxy sheet is a versatile, durable, and reliable material. It offers higher mechanical strength, chemical and moisture resistance, electric insulation, thermal stability, and so on. These qualities make G10 sheets highly desired for applications in marine, aerospace, automotive, electric, etc. industries.

Finally, we suggest professionals consider this elaboration on what is G10 epoxy sheet to incorporate the full potential of G10 fiberglass epoxy laminates.

UVTECO is a leading supplier of G10 epoxy sheet in China, provides sheet, rod and tube. If you are looking for a trustworthy supplier of G10, Contact UVTECO now!

Related Blogs

Looking for a trustworthy Supplier

Need a Trustworthy Supplier of Plastic, Foam, Sponge, Rubber, Metal, and Machining Solution. Click the Button, We Will Be In Touch With You As Quickly As Possible.