Everything you need to know about Rapid Tooling

In the engineering product design process, rapid tooling is necessary for the low-volume manufacturing of plastic parts, these parts can be used for design validation. You may wonder how to make rapid tooling, and how it works. Today, we will discuss rapid tooling.

What is Rapid tooling?

Rapid tooling is a technology, which is used to make mold tooling fast, helping manufacturers to produce parts with actual production grade of material at a low cost and short time. It is also known as soft tooling which uses different tooling materials with mass production tooling.

4 methods for making Rapid tooling

Generally, there are four common methods to make rapid tooling in a short time, see the following.

Indirect molding tooling

The indirect tooling method uses a master pattern as the base and creates the tooling to surround this master pattern, the cavity and core of the tooling will be formed the same as the master pattern. Silicone mold is the common application created by this method to produce plastic parts.

Direct tooling

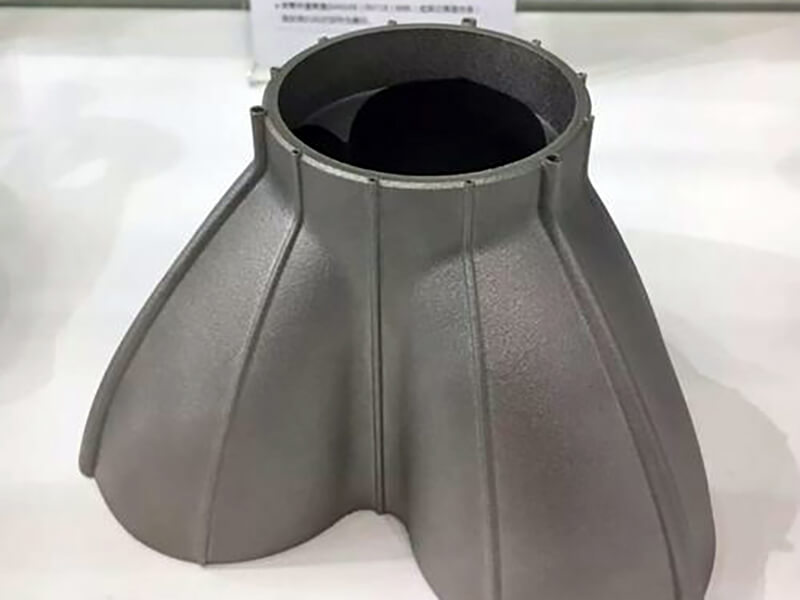

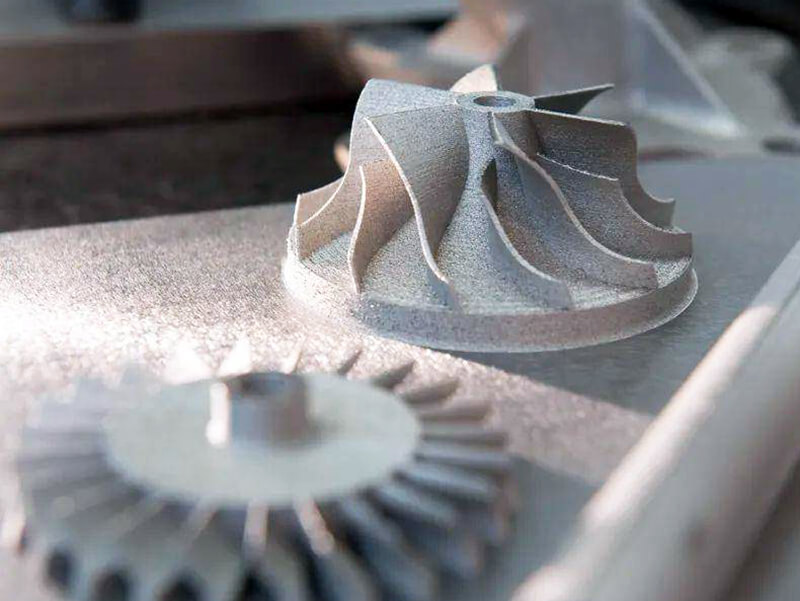

Metal 3D printing technology can be used for producing rapid tooling in a very short time directly based on the tooling 3D data. These 3D-printed toolings can be used for injection molding, vacuum forming, etc.

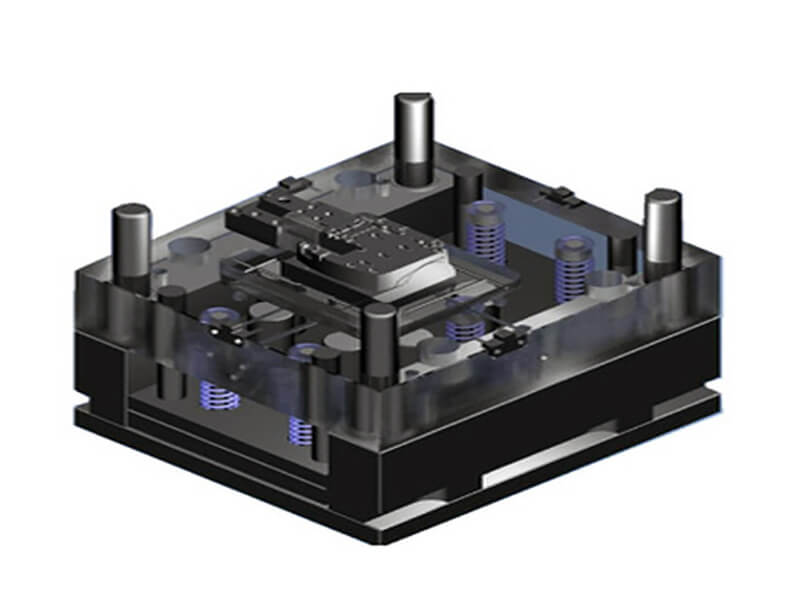

CNC Machined Rapid Tooling

CNC Machining is the method to create both rapid tooling and mass production tooling. Unlike traditional mass-production tooling typically made from robust metals like hard steel or nickel alloys, rapid tooling is often machined from materials such as aluminum alloys and soft steel.

3D Printed Rapid Tooling

Direct tooling means creating the tooling directly on a metal block with machining techniques such as CNC machining, Wire EDM cutting, and 3D printing to shape the metal block to be tooling components. This method usually requires creating the tooling 3D data with CAD software and then using the data for machining.

Four Tips for Making a Rapid Tooling

Even creating rapid tooling is much easier than creating mass production molding tooling, but there are also lots of techniques during the manufacturing process to save cost and improve tooling quality. Here are some tips for making a rapid tooling as below:

3D Printing Rapid Tooling Vs. Machining Rapid Tooling

| Item | Conventional Molds & Tooling | 3D Printed Plastic Molds & Tooling | 3D Printed Metal Molds & Tooling |

|---|---|---|---|

| Cost | High | Low | low |

| Leading time | Long | Short | short |

| Cooling time | long | Long | Short |

| Durability | High | Low | High |

| Flexibility | Low | High | High |

Rapid Tooling vs Rapid Prototyping

Rapid prototyping uses a set of techniques to create a physical model or final part according to 3D data created in CAD software. The techniques include CNC machining, 3D printing, vacuum casting, dyeing technology, polishing process, etc.

On the other hand, rapid tooling uses machining processes not for producing the actual parts directly, but for creating tooling components like molds, dies, or patterns. rapid tooling will be used for producing the final parts.

Hard Tooling vs. Soft Tooling

Hard tooling is made of hard steel for injection molding which can support high volume production. However, it has significantly higher costs compared to soft tooling or most rapid tooling methods.

Soft tooling usually means silicone molds for the urethane casting process. it is used to create prototypes and low-volume parts to make sample tests. The urethane has similar properties to the original material.

frequently asked questions

What is the lead time for you to make a rapid tooling?

Around 2 to 4 weeks, we can produce silicone mold in less than 2 weeks, and produce aluminum and soft steel tooling in less than 4 weeks.

What materials are used in rapid tooling?

Plastic, silicone rubber, and urethane are commonly used in rapid tooling to create parts with injection molding and casting process.

Applications of Rapid Tooling

Injection molding

Injection molding is widely used for manufacturing plastic, silicone, and rubber components. Rapid tooling with soft steel is created mostly for this application to inject parts with the same materials used in the hard tooling, but the rapid tooling offers a better price.

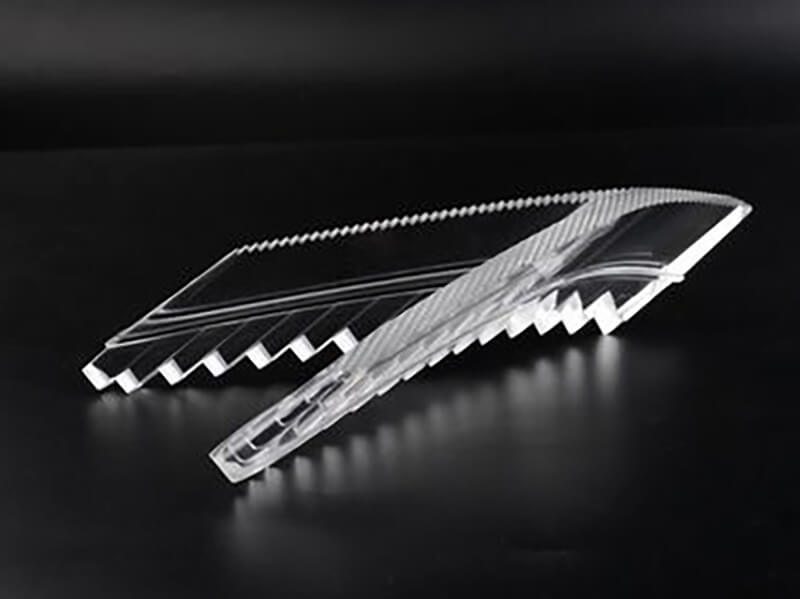

Thermoforming

Rapid tooling with low-cost tooling material can be used for thermoforming to create products that are easier to make with the thermoforming process. The common materials of thermoforming molding tools are wood, fiberglass, aluminum, etc.

Sheet Metal Forming

Rapid tooling is also used a lot in forming metal sheets to make quick tooling for sheet metal bending with an accurate result.

Final words

When you need a small volume of products from 100 pieces to 1000 pieces of plastic parts, Injection molding with rapid tooling is a perfect choice. UVTECO provides low-volume injection molding services and can help produce your products within a very short time and at a very low cost.

Related Blogs

Looking for a trustworthy Supplier

Need a Trustworthy Supplier of Plastic, Foam, Sponge, Rubber, Metal, and Machining Solution. Click the Button, We Will Be In Touch With You As Quickly As Possible.