PEEK vs PEK vs PTFE Materials: A Detailed Comparison Guide

Get the complete details about PEEK, PEK, and PTFE materials! Find out how they are different and which one you should choose for your industry needs.

If you are choosing the right material for your industrial needs, the three common options you might come across: PEEK, PEK, and PTFE. Each of these materials has its own unique characteristics that give it stability for different purposes, but the question remains: how do they compare?

PEK is famous for its strength and ability to handle extreme heat, while PEK competes with PEEK with its mechanical properties. Besides, PTFE, on the other hand, is known for its non-stick surface.

Don’t get confused. Read our comprehensive PEEK vs. PEK vs. PTFE guide and ensure the best material for your projects.

PEEK vs. PEK vs. PTFE Materials: A Quick Comparison Table

| Parameter | PEEK | PEK | PTFE |

|---|---|---|---|

| Tensile Strength | 170 Mpa | 120 MPa. | 25-35 Mpa |

| Elongation | 30-40% | 4% | 350-400% |

| Compressive Strength | 140 Mpa | 25–100 MPa | 30-40 Mpa |

| Coefficient of Friction | 3900 Mpa | 0.08 | 495 Mpa |

| Temperature Resistance | Up to 250°C | Up to 160°C | Up to 250°C |

| Dielectric Strength | 50 Kv/mm | 62 Kv/mm | 50-150 Kv/mm |

| Chemical Resistance | Affected by Sulphuric acid | Good chemical-resistant material | Virtually inert |

| Machine-ability | Very good | Good | Good |

What is PEEK Material?

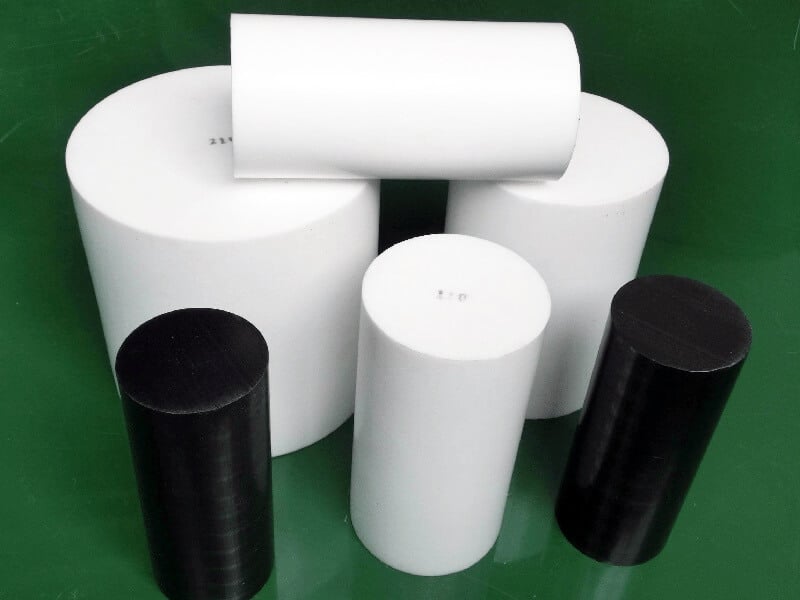

PEEK is a well-known semi-crystalline engineering thermoplastic. It features high-frequency mechanical and physical properties. Due to its exceptional mechanical strength, good dimensional stability, and excellent resistance, it is now a reliable choice for a wide temperature range of applications.

This means it keeps its rigidity and strength and is good at handling tough situations. This makes PEEK perfect for things that can tolerate high stress the most.

What is PEK Material?

PEK is another semi-crystalline thermoplastic known for its high thermal stability, chemical resistance, and mechanical properties. It is made from special materials called ketones, which ensure its solid balance in all environments. In almost every complex environment, it stays strong and maintains its stability.

Like PEK, it is widely used in various applications, including the aerospace and automotive industries, to make gears, shafts, bearings, and many other materials.

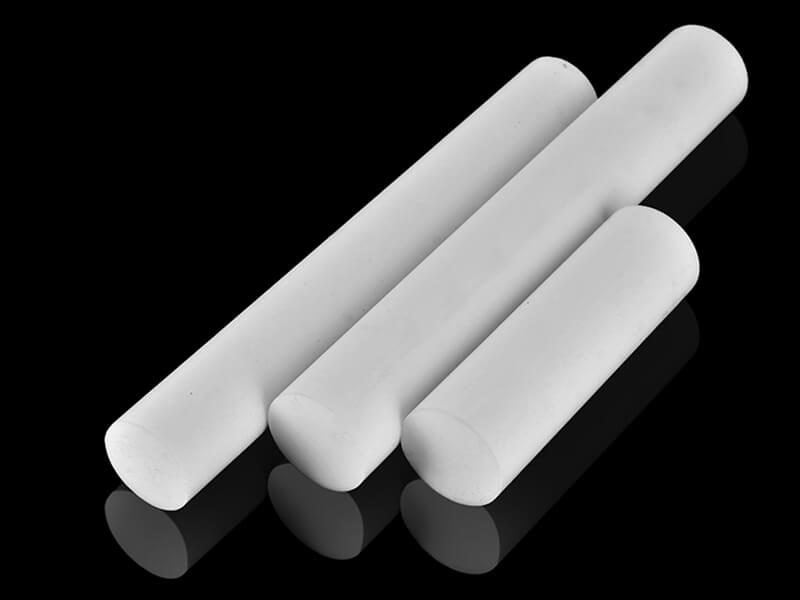

What is PTFE Material?

PTFE is a synthetic fluoropolymer material known by its trade name Teflon®. The material mainly features non-stick properties, which help it stay dry in all conditions. Plus, its thermal stability and chemical and mechanical stability are also superior.

This material is commonly used in non-stick coatings for cookware. It is also used to make rollers, seals, seal rings, and many heated hair tools.

Key Differences Between PEEK, PEK, and PTFE Materials

To get the right difference between PEEK, PEK, and PTFE, here are some key factors to pick the right materials for your needs.

1. Tensile and Impact Strength

PEEK is a strong plastic that can easily handle excessive forces before it starts to break or crack. Its tensile strength is 170 MPa. It tells us that the polymer can withstand 170 million Pascals of pressure, and after that, it might break down.

Due to its superb strength, it is effectively used in many harsh environments, like cars, airplanes, or even medical tools. PEK is also a strong material, though not as strong as PEEK. It can easily handle pulling or stretching forces up to 120 MPa.

Though moderate, it is used in things like car parts or electrical insulation. Compared to both polymers, PTFE is much weaker, with a tensile strength of around 25-35 MPa.

2. Temperature Resistance

PEEK is a high-tolerance thermoplastic. It shows excellent thermal stability with a temperature range between -40°C to 250°C and short-term peaks up to 300°C. Its melting point is around 341°C or 646°F, and after that, it starts melting down.

PEK also offers an impressive resistance to temperature environments that work from -300°F to +500°F. Its melting point is around 341°C or 646°F, and it starts melting down.

PEK also offers impressive resistance to temperature environments from -300°F to +500°F. Its melting temperature is about 343°C or 662°F, which is similar to PEEK.

3. Wear Resistance

PEEK is a high-quality thermoplastic with very low wear and friction characteristics, which gives it stability in all harsh conditions. However, under dry conditions, its COF rate is low and wears out at 1.52 × 10⁻¹⁴ m²/N.

But it shows impressive resistance under water-lubricated conditions where the wear rate drops to 4.55 × 10⁻¹⁵ m²/N. Coming to PEK, it also offers higher wear resistance. As a high-quality resin, a PEK coating doesn’t wear out much, even when things slide against it.

At the same time, PEEK wears down by 105 micrometers. It is clear that both PEK and PEEK are equally slippery, but PEK lasted longer. PTFE is a comparatively poor wear-resistant polymer that is even more affected by rising temperatures.

4. Chemical Resistance

PEEK shows exceptional chemical resistance compared to other polymers. It can effectively work against organic and inorganic compounds and shows stability. For example, up to 37% of hydrochloric acid can stay strong for up to 48 hours.

The same applies for pH levels up to 1-12.5. PEK also delivers very good chemical resistance to almost all common non-oxidizing acids and solvents. Virgin PTFE is good at resisting harsh chemicals, with some exceptions, like liquid alkali metals and fluorine.

So, when choosing these polymers’ solid chemical resistance, PTFE wins as virtually inert.

5. Mechanical Strength

When it comes to mechanical strength, PTFE is super stretchy. It can stretch 350-400%, which tells us that if you have a 1-meter PTFE, it can stretch up to 4 to 5 meters long without any damage.

On the contrary, PEEK is not as stretchy as PTFE, though its elongation can only stretch up to 30-40%. Unfortunately, PEK is the least stretchy of the three. It can only stretch 4% and may break down if you apply enough pressure or a high load.

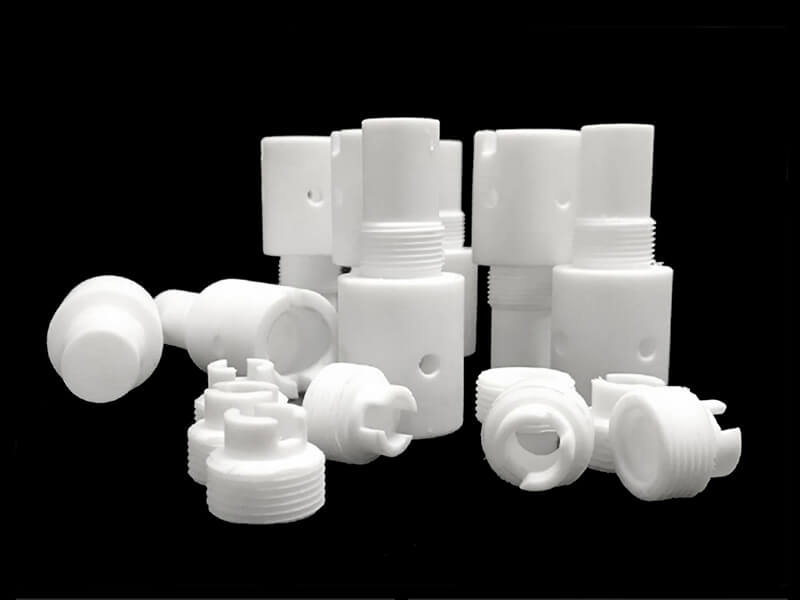

6. Machine-Ability

PEEK is a high-quality machinable thermoplastic that can be molded or machined to your desired shape. From machining to injection molding, it offers superior stability and maintains its configuration.

It can easily handle the high tool infeeds and high feed rates and produce quality results. PTFE is also a high-performance machinable polymer that provides exceptional wear, impact, and fatigue throughout the machining process. But due to machining stability, it stays more stable than PTFE. Also, due to improved toughness and strength, you can also use PEK for machining.

Conclusion

Sometime, you can use one of three materials for you project, because PEEK, PEK and PTFE offers good Temperature Resistance, therefore, choosing cheapest material is the best solution.

Most project, you need to choose PEEK Material, although it is very expensive, because it is a perfect material for impact resistance, temperature resistance, wear resistance, chemical resistance, etc.

If you don’t know the best material, and need a partner for your project, UVTECO as a leading supplier and expert in engineering plastic in China, will help you. Contact us now!

Related Blogs

Looking for a trustworthy Supplier

Need a Trustworthy Supplier of Plastic, Foam, Sponge, Rubber, Metal, and Machining Solution. Click the Button, We Will Be In Touch With You As Quickly As Possible.