Polypropylene Vs. ABS Plastic: Decoding the Properties

Polypropylene or ABS Plastic? This article helps to discover the differences in properties, uses, and benefits of the two materials.

Polypropylene plastic is basically a thermoplastic made of Polypropylene. This semi-crystalline polymer is widely used in various industries to produce high-quality products. On the other hand, the full form of ABS plastic is Acrylonitrile Butadiene Styrene. It is also known as graft copolymer and contains three particular monomers; acrylonitrile, butadiene, and styrene. ABS plastic is usually used in various molding and injecting applications.

However, having an in-depth knowledge of the properties, applications, advantages, and disadvantages of these plastics assists professionals in selecting the right material. In this article, we detail Polypropylene Plastic vs ABS Plastic while covering the related aspects to differentiate these two competing materials.

Polypropylene Plastic: Everything You Need to Know

Polypropylene plastic was invented in 1951 by two Phillips Petroleum scientists, Paul Hogan and Robert L. Banks. Giulio Natta and Paolo Chini developed isotactic polypropylene in 1954. Finally, the commercial production of Polypropylene plastic started in 1957.

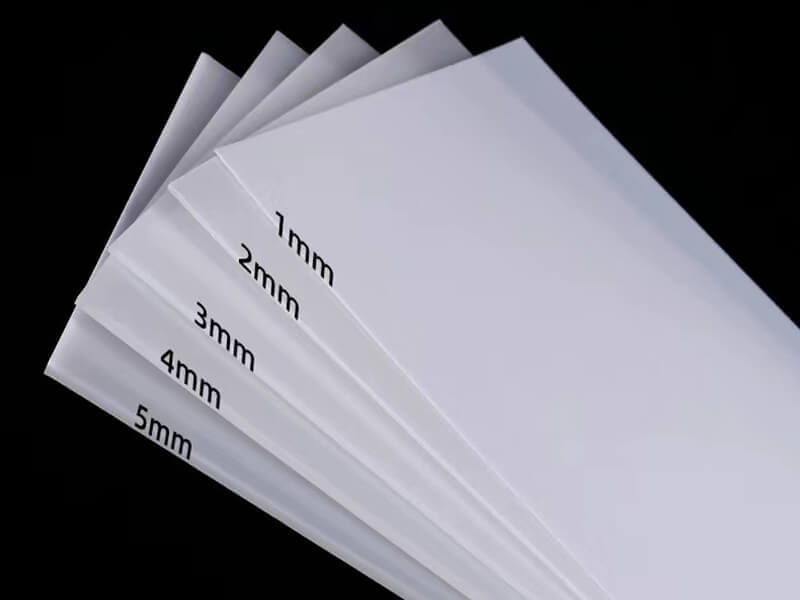

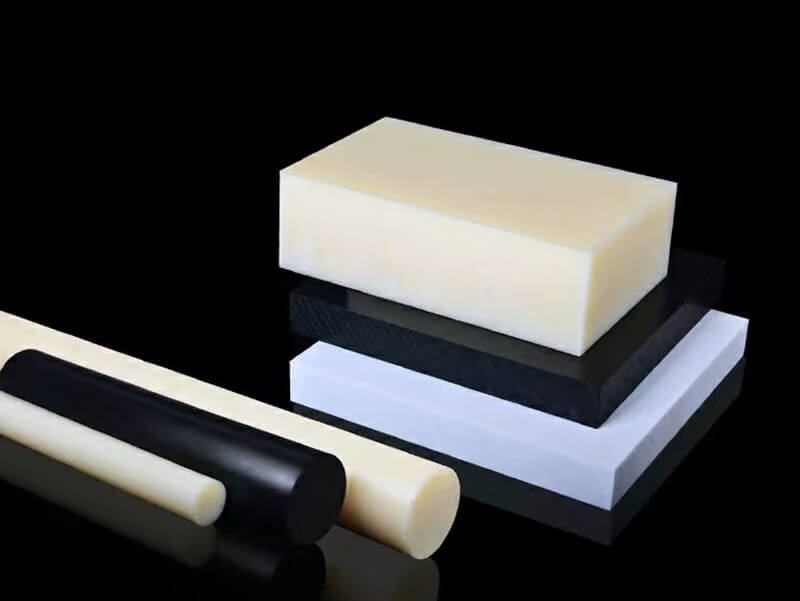

The manufacturing of Polypropylene (PP) is a complex polymerization process. Here, propylene gas undergoes a controlled transformation in the presence of a Ziegler-Natta or metallocene catalyst. Later, the PP pallets are placed in a large cylindrical barrel, and an appropriate amount of heat and pressure is applied. This causes them to melt and form a homogenous molten mass. Finally, the molten mass is framed in different shapes like sheets, Films, Rods, Etc.

Common Characteristics of Polypropylene Plastic

Here are the basic properties of this plastic material.

Common Applications of Polypropylene Plastic

We list the most common applications of Polypropylene plastic.

Advantages of Polypropylene plastic

The below benefits are offered by Polypropylene plastic:

Disadvantages of Polypropylene Plastic

The following are the common issues of this material.

ABS Plastic: Everything You Need to Know

ABS plastic was developed in 1948, and it is a US-based patent. The Borg Warner Corporation brought it to the commercial market in 1954. However, in general, there are two processes available to produce ABS plastic. In the first process, chains of polybutadiene are combined with a backbone chain of styrene-acrylonitrile copolymer (SAN). Finally, the respective complex molecular structure forms ABS plastic.

The second process is called the emulsion process. Here, polybutadiene is prepared as a watery latex in the first step. Then, styrene and acrylonitrile are added to this latex. The three constituents – polybutadiene, styrene, and acrylonitrile – undergo a copolymerization process in controlled condition. Finally, ABS plastic is produced.

The full name of ABS plastic is Acrylonitrile Butadiene Styrene, a common thermoplastic polymer derived from acrylonitrile, butadiene, and styrene. The glass transition temperature is approximately 105 °C (221 °F), and it is amorphous and, therefore, has no true melting point.

Common Characteristics of ABS Plastic

Below is a list of the base characteristics of ABS Plastic:

Common Applications of ABS Plastic

Some of the general use of ABS plastic we inform you in this section.

Advantages of ABS Plastic

Here are some must-know advantages of this material.

Disadvantages of ABS Plastic

Below are the issues with ABS plastic.

Comparison Between Polypropylene Plastic Vs. ABS Plastic

| Type | Polypropylene Plastic | ABS Plastic |

|---|---|---|

| Short description | Polypropylene plastic is a thermoplastic | ABS plastic is Acrylonitrile Butadiene Styrene and is known as graft copolymer |

| What ingredients used to make this | Propylene gas, Ziegler-Natta or metallocene catalyst | Polybutadiene, styrene, and acrylonitrile |

| Applications | Polypropylene plastic is used to manufacture furniture, toys, boards, signages, etc. | ABS Plastic is used to make 3D building materials, prototypes, keyboard keys, various tools, autobody components, etc. |

| Characteristics | It provides a higher degree of strength and durability. It has chemical and stress resistance capabilities. It is also flexible. | It has corrosion, strain, abrasion, and direct impact resistance capabilities. Easy to process. Low melting point. |

| Trade Name | Proteus, Propylux, etc. | Cycogel, etc. |

| Price | Per Ton Polypropylene plastic price ranges from $1,283 to $1,350 | The per pound price is $1.50 to $2.34. |

Final Thoughts

Many people can’t identify Polypropylene and ABS plastic if they are the same color. They are different materials, including working temperatures, physical properties, applications, features, etc.

If you don’t know how to choose a suitable material for your project, please contact UVTECO. As an expert in material and machining solutions, UVTECO is a trustworthy supplier of Polypropylene plastic and ABS plastic from China, and we will help you choose the right material for your projects.

Related Blogs

Looking for a trustworthy Supplier

Need a Trustworthy Supplier of Plastic, Foam, Sponge, Rubber, Metal, and Machining Solution. Click the Button, We Will Be In Touch With You As Quickly As Possible.