Acetal Vs. ABS Plastic: A Comprehensive Comparison

Knowing the key differences between the two plastics is crucial when trying to figure out the right one. Discover the main variations between Acetal plastic and ABS plastic and make the correct choice.

Before choosing your material, it is very important to know about the properties, strong points, advantages, and weaknesses of different plastics. This is because rigidity, impact strength, machinability, and several other properties vary from plastic to plastic. Without knowing them throughout, it will be hard to make informed decisions, making you unable to make the most out of your investment.

As for Acetal and ABS, they are high-quality plastics known for their durability. However, they also do have distinctive differences. Thus, in this article, we will explain in detail about both the products, so you are not confused and can make the most out of your purchase.

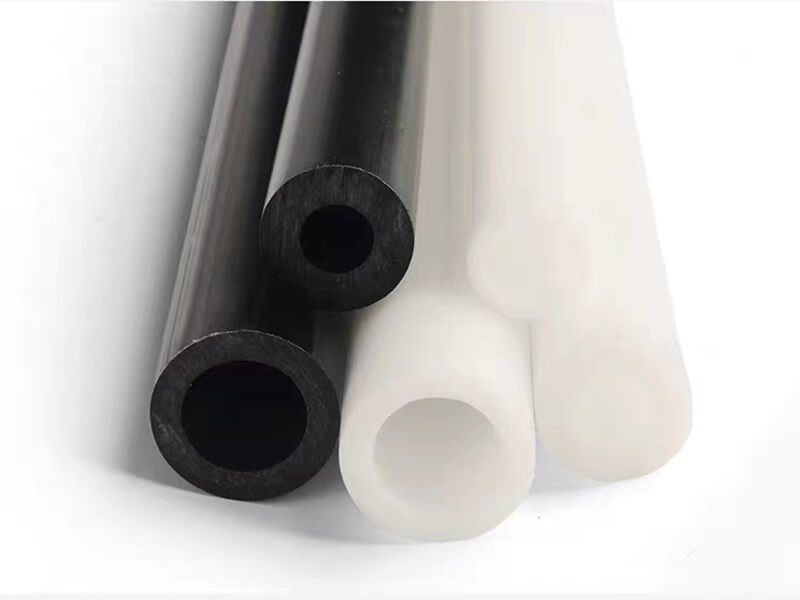

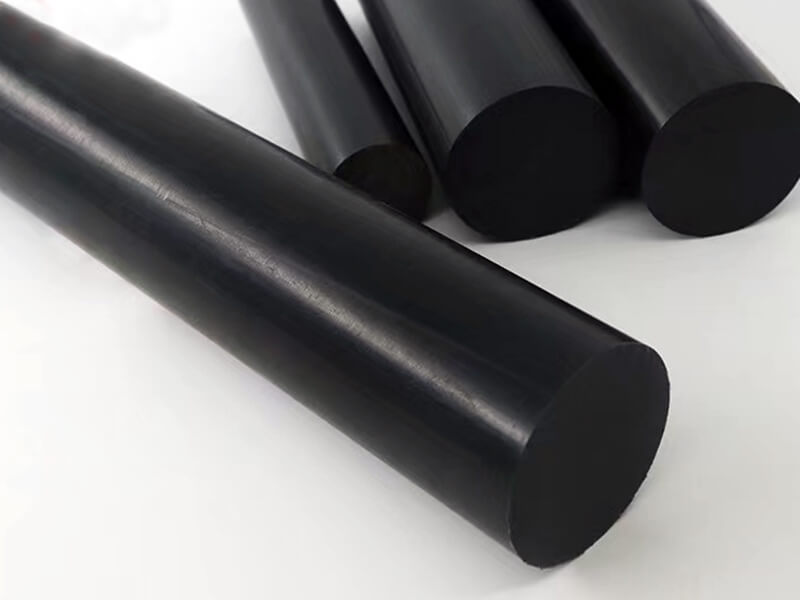

Acetal Plastic: Everything You Need To Know

Acetal plastic is a semi-crystalline thermoplastic known as POM plastic (polyacetal). It is primarily based on formaldehyde molecules. The plastic can also be found in other variants, such as polyformaldehyde, polyethylene glycol, or polyoxymethylene glycol.

This leads to acetal plastic being used as an alternative to metal due to its impressive durability. Moreover, the combination of compounds allows the plastic to have good mechanical and chemical properties. Overall, it is suitable for various applications and industrial uses.

Common Characteristics Of Acetal Plastic

Here are some common characteristics of standard Acetal Plastic

Common Applications of Acetal Plastic

Due to the multipurpose characteristics of this plastic, it is used for a variety of causes in both general purpose and industrial sectors. Here are some of its uses

Advantages of Using Acetal Plastic

Disadvantages of Using Acetal Plastic

ABS Plastic: Everything You Need to Know

ABS, short for Acrylonitrile butadiene styrene, is a type of thermoplastic polymer mainly made with the three components in its name.

The compound structure of this plastic makes it superior to most other manufacturing plastics. ABS plastic is known for its high structural strength, thermal endurance capacities, impact resistance, and much more. This leads to plastic being a common material in several industries nowadays. Not only that, its easy-to-use features make it an ideal material for personal or artistic use too.

Common Characteristics of ABS Plastic

Here are some characteristics of ABS plastic that differentiate it from other available plastics.

Common Applications Of ABS Plastic

Due to such versatile properties, it is a common material in terms of use in several industries.

Advantages of Using ABS plastic

Disadvantages Of Using ABS Plastic

Comparison Between Acetal vs ABS Plastic

| Item | Acetal Plastic | ABS Plastic |

|---|---|---|

| Short Description | Acetal is rigid, durable, and has high tensile strength. It has excellent dimensional stability and chemical resistance. | ABS is a thermoplastic polymer |

| What ingredients were used to make this | Several toolbox instruments, automobile, food industry, and medical sector instruments are made using it. | Several toolbox instruments, such as automobile, food industry, and medical sector instruments, are made using it. |

| Applications | Acetal is rigid, durable, and has high tensile strength. It has excellent dimensional stability and chemical resistance. | Toys, keyboards, protective housing for tools, and car parts are made using ABS |

| Characteristics | Acetal is rigid, durable, and has high tensile strength. It has excellent dimensional stability and chemical resistance. | ABS provides great structural and thermal stability. High electrical insulating capabilities and corrosion and abrasion resistance. |

| Tensile Strength | 10,000 | 6500 |

| Coefficient of linear thermal expansion | 6.8 | 6.3 |

related Blogs

Looking for a trustworthy Supplier

Need a Trustworthy Supplier of Plastic, Foam, Sponge, Rubber, Metal, and Machining Solution. Click the Button, We Will Be In Touch With You As Quickly As Possible.