About Polypropylene (PP) plastic

Polypropylene (PP) plastic is a thermoplastic polymer developed for commercial application in 1957. It is also known as polypropene and includes Homopolymer and copolymer grades.

As a popular engineering plastic, Polypropylene (PP) offers excellent chemical resistance to acids, alkalis, and solvents. It is also easily welded and machined. Therefore, polypropylene (PP) plastic is frequently used to lining structural tanks, plating barrels, orthotic and prosthetic devices, and pump and valve components. In addition, polypropylene (PP) plastic is commonly used in semiconductor and chemical industries due to its superior durability in corrosive environments.

Polypropylene (PP) doesn’t absorb moisture. It is stranger than High-Density Polyethylene (HDPE) and offers good abrasion resistance, moisture resistance, and formability. Homopolymer polypropylene (PP) plastic works well between -4°F (-20°C) to 212°F (100°C) and can be thermoformed into different shapes. Therefore, polypropylene (PP) plastic is found in medical, automotive, packaging, and consumer products.

Specification about Polypropylene (PP) Plastic

Profile/Shape

Grade

Color

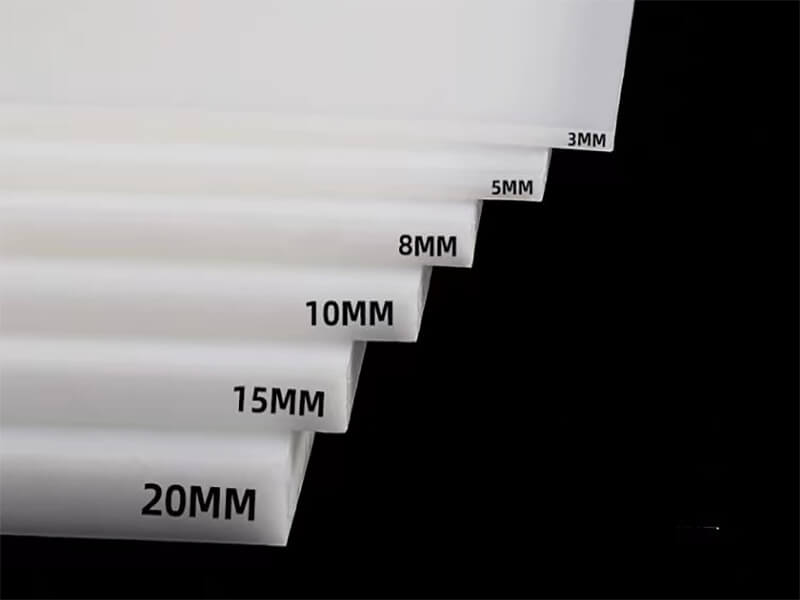

Sheet/Block

PP Film

PP Rod

PP Tube

Remark

Properties of Polypropylene plastic

Main Usage of Polypropylene Plastic

Main Feature of Polypropylene Plastic

Industry

Can’t find what you need? Or need a custom Polypropylene (PP) Plastic?

Leading Supplier of Polypropylene (PP) Plastic In China

As an ISO-certified company, UVTECO is one of the leading suppliers of high-quality Polypropylene (PP) Plastic Sheets/Rods in China. We stock standard colors and sizes for fast delivery. Meanwhile, UVTECO provides an integrated machining solution for PP-based parts/components. The main machining methods include cutting, drilling, 3-axis and 5-axis CNC milling, CNC Turning, injection molding, thermal forming, routing, etc.

Now, we provide high-quality PP Plastic Sheets/Rods and parts/components for more than 2,500 clients from more than 45 countries. They work in the environmental protection, wastewater treatment, automation, automobile, Food industry, shipbuilding, aerospace, appliance, electrical, and electronic industries.

Polypropylene (PP) product that UVTECO supply

Polypropylene (PP) Tube

Polypropylene (PP) Film

Contact UVTECO for machining Polypropylene (PP) plastic

Related Blogs about Polypropylene (PP) plastic

Frequently Asked Questions about Polypropylene (PP) plastic

Looking for a trustworthy Supplier

Need a Trustworthy Supplier of Plastic, Foam, Sponge, Rubber, Metal, and Machining Solution. Click the Button, We Will Be In Touch With You As Quickly As Possible.