Polypropylene Rods In Stock

Homopolymer, Flame retardant, Glass-filled, Diameter from 4mm to 400mm, Machining Service…About Polypropylene Rods

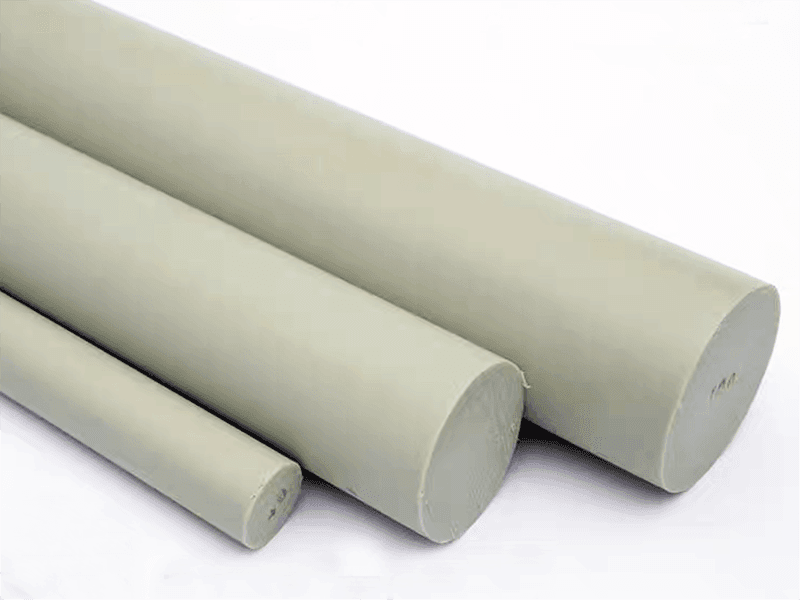

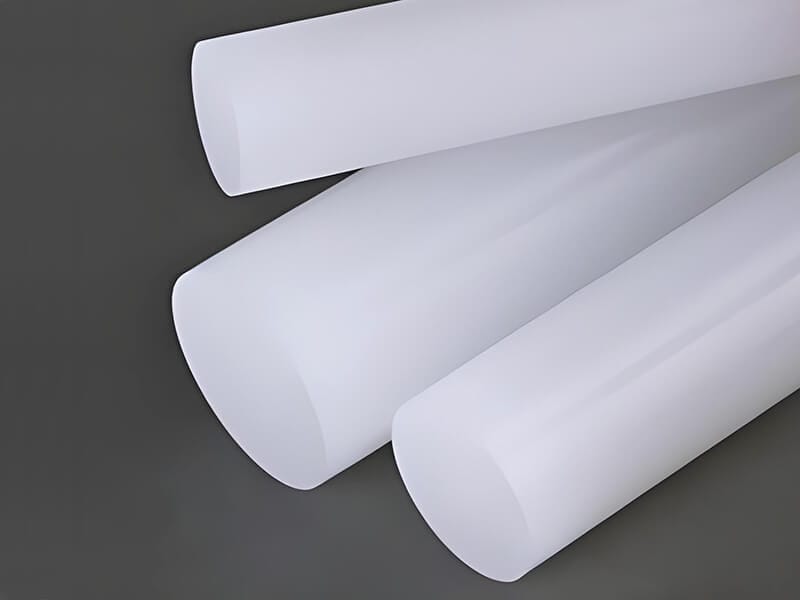

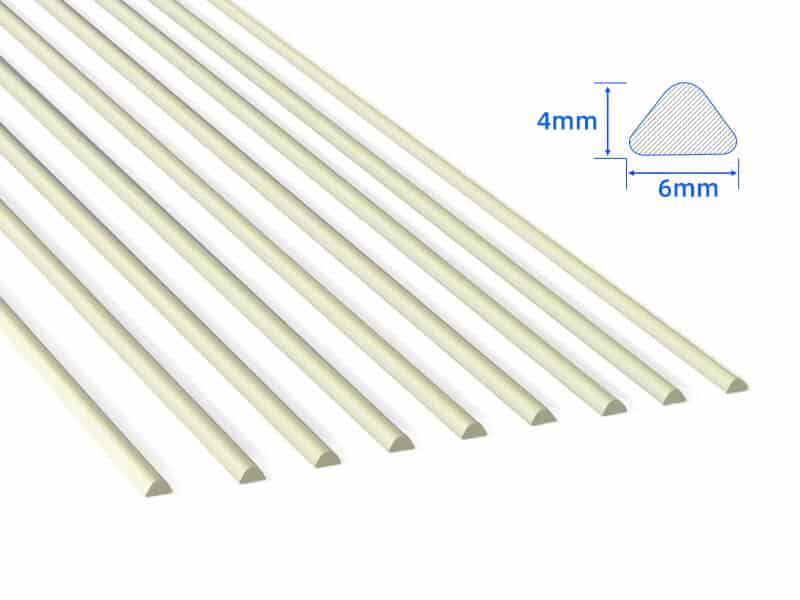

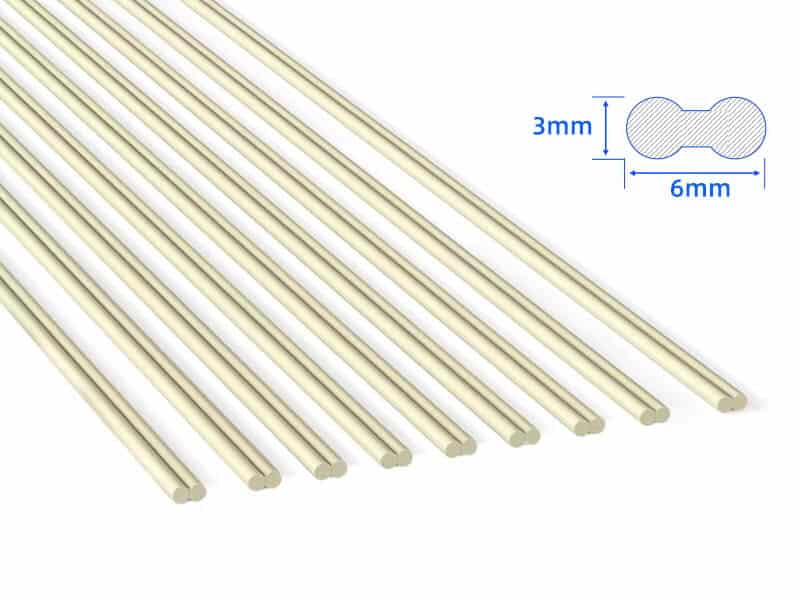

Polypropylene Rods are produced with high-quality polypropylene homopolymer plastic by the extrusion process. The common colors are translucent, white, grey, and black. Normally, the diameter is from 4mm to 400mm, and the standard length is 1000mm or 2000mm.

Polypropylene rods offer good hardness and excellent chemical resistance. It is an economical plastic rod as an alternative to HDPE rods or ABS rods.

Normally, it can be machined by a CNC lathe turning machine. It is the right material for chemical processing and storage applications.

Specification about Polypropylene Rods

Polypropylene Rods in stock

UVTECO stocks Polypropylene Rods from 0.5mm to 400mm in diameter. The colors include Translucent, Grey, White, and Black. Otherwise, we can machine Polypropylene rods according to drawings.

Grade

color

Properties of Polypropylene Rod

Main Usage of Polypropylene Plastic

Main Feature of Polypropylene Plastic

Industry

Can’t find what you need? Or need a custom Polypropylene Rods?

Leading Supplier of Polypropylene Rods In China

As an ISO-certified company, UVTECO is one of the leading suppliers of high-quality Polypropylene Rods in China. We stock Polypropylene Rods with various colors and diameters for fast delivery. Meanwhile, UVTECO provides an integrated machining solution for PP-based parts/components. The main machining methods include cutting, lathe turning, drilling, 3-axis and 5-axis CNC milling, routing, etc.

Now, we provide high-quality Polypropylene Rods and parts/components for more than 2,500 clients from more than 45 countries. They work in environmental protection, wastewater treatment, automation, automobile, Food industry, shipbuilding, aerospace, appliance, electrical, and electronic industries.

Contact UVTECO for machining Polypropylene Rods

Related Blogs about Polypropylene Rods

Frequently Asked Questions about Polypropylene Rods

Looking for a trustworthy Supplier

Need a Trustworthy Supplier of Plastic, Foam, Sponge, Rubber, Metal, and Machining Solution. Click the Button, We Will Be In Touch With You As Quickly As Possible.