A Beginner’s Guide: How to Identify Polypropylene Plastic

A wide variety of plastics are available in the market, and each has unique characteristics, advantages, disadvantages, etc. In this case, identifying the plastic type is crucial for professionals and users.

By considering the higher degree of importance and use of polypropylene plastic, we will inform you how to identify polypropylene plastic in this article. You can correctly differentiate Polypropylene Plastic from others using this beginner’s guide.

Basics of Polypropylene Plastic

Polypropylene, also known as PP plastic, is a versatile thermoplastic polymer belonging to the polyolefin family. The polymerization of propylene monomers creates it. Due to its superior characteristics, polypropylene is widely used in various industries.

Characteristics of Polypropylene

A Comparison between PP, PE, and PVC

| Differential Criteria | PP | PE | PVC |

|---|---|---|---|

| Density | Ranges from 0.895 and 0.92 g/cm³ | Ranges between 0.910 and 0.940 g/cm3 | Ranges between 1.1 to 1.45 g/cm³ |

| Chemical Resistance | Higher than PE and lower than PVC | Lower than PP and PVC | Higher in this group |

| Heat Resistance | Higher than PE and lower than PVC | Lower than PP and PVC | Higher in this group |

| Flexibility | Higher than PVC and lower than PE | Higher in this group | Lower in this group |

| Recyclability | Resin identification code #5 | Resin identification code #1 | Resin identification code #3 |

How to Identify Polypropylene Plastic

To correctly identify polypropylene plastic, consider performing at least two examination methods, as mentioned below.

Method 01: Physical Inspection

In this plastic identification method, your first task is to look for the “International Code” on the plastic. This code consists of three arrows forming a triangle (often known as a recycling sign), and in between it is a symbol indicating the plastic’s name. Note the below symbols to identify Polypropylene.

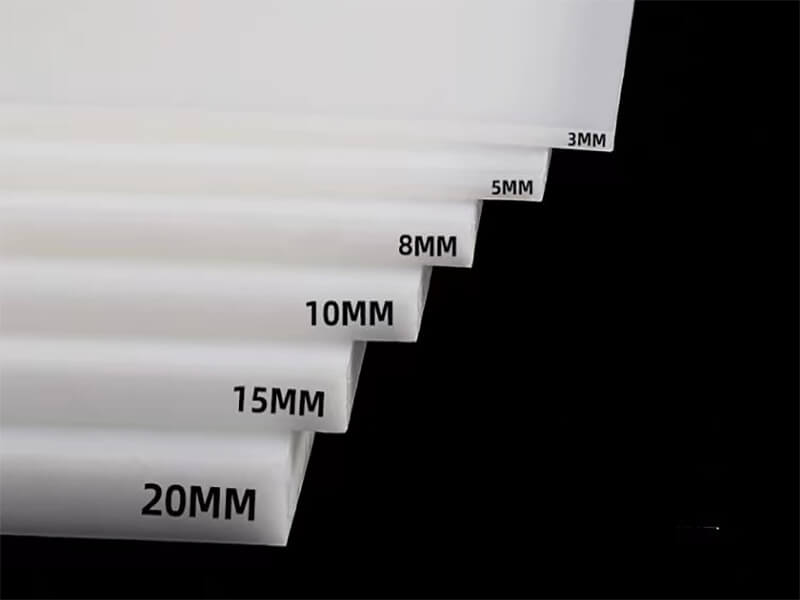

Next, check the color and appearance of the respective plastic. In general, Polypropylene plastic is translucent or semi-translucent. It comes in various colors; white, black, and various shades of blue, green, or beige.

Finally, check the flexibility of the plastic material. If it is made of Polypropylene, it will bend without breaking easily. Below are the two points that need to be considered.

Method 02: Identification of Polypropylene Plastic Using Float Method

Follow the stepwise guidelines.

Step 01: Arrange a clean container.

Step 02: Fill the container with clean water. We suggest the water be free of impurities, which increases its density.

Step 03: Take a small piece of the respective plastic.

Step 04: If the plastic is made of polypropylene, it will float due to its low density. Most essentially, low-density polyethylene even remains above the water.

Method 03: Testing the Plastic Chemically

This method consists of two approaches: burning and solvent tests.

Burning Test: Take a piece of examining plastic and fire it up. If it generates dirty engine oil and undertones of candle wax, it indicates that the material is Polypropylene Plastic. However, upon burning, PP produces water vapor and CO2.

Solvent Test: At first, put a piece of the examining plastic in isopropyl alcohol or mineral spirits. If the plastic is made of Polypropylene, it won’t get dissolved or react with the solvent. Again, to be more sure, Second, put a piece of the respective plastic in benzene and acetone. Polypropylene plastic will get dissolved in the solvents of benzene and acetone.

Method 04: Laboratory Test

Many laboratories and survey companies perform plastic identification testing on individual clients. They usually use Fourier-transform infrared (FTIR) spectrometers, Gas Chromatography-Mass Spectrometry (GC-MS) machines, etc., to identify the plastic category. However, this testing method is subject to a fee.

Final Words

Understanding how to identify Polypropylene plastic is certainly essential. This knowledge facilitates the correct use of construction materials, responsible recycling, etc. You can confidently differentiate polypropylene from other plastics using the abovementioned methods, such as visual inspection, density, float, and chemical tests.

Finally, UVTECO has the rich experience in plastic material use and handling also contributes to its identification process. If you don’t know how to identify Polypropylene, contact UVTECO, an expert in material and machining solutions. We can help you.

Related Blogs

Looking for a trustworthy Supplier

Need support in Plastic, Foam, Sponge, Rubber, metal and machining solutions. Click the button, and we will be in touch with you as quickly as possible.